Pectin oligosaccharide containing fine dried noodles and preparation method thereof

A technology of pectin oligosaccharides and dried noodles, which is applied in the field of food processing, can solve the problems of low utilization rate of raw materials, low pectin extraction rate and yield, lack of formula technology for nutritional and health-type dried noodles, etc., to ensure cooking performance, The effect of enriching variety and increasing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

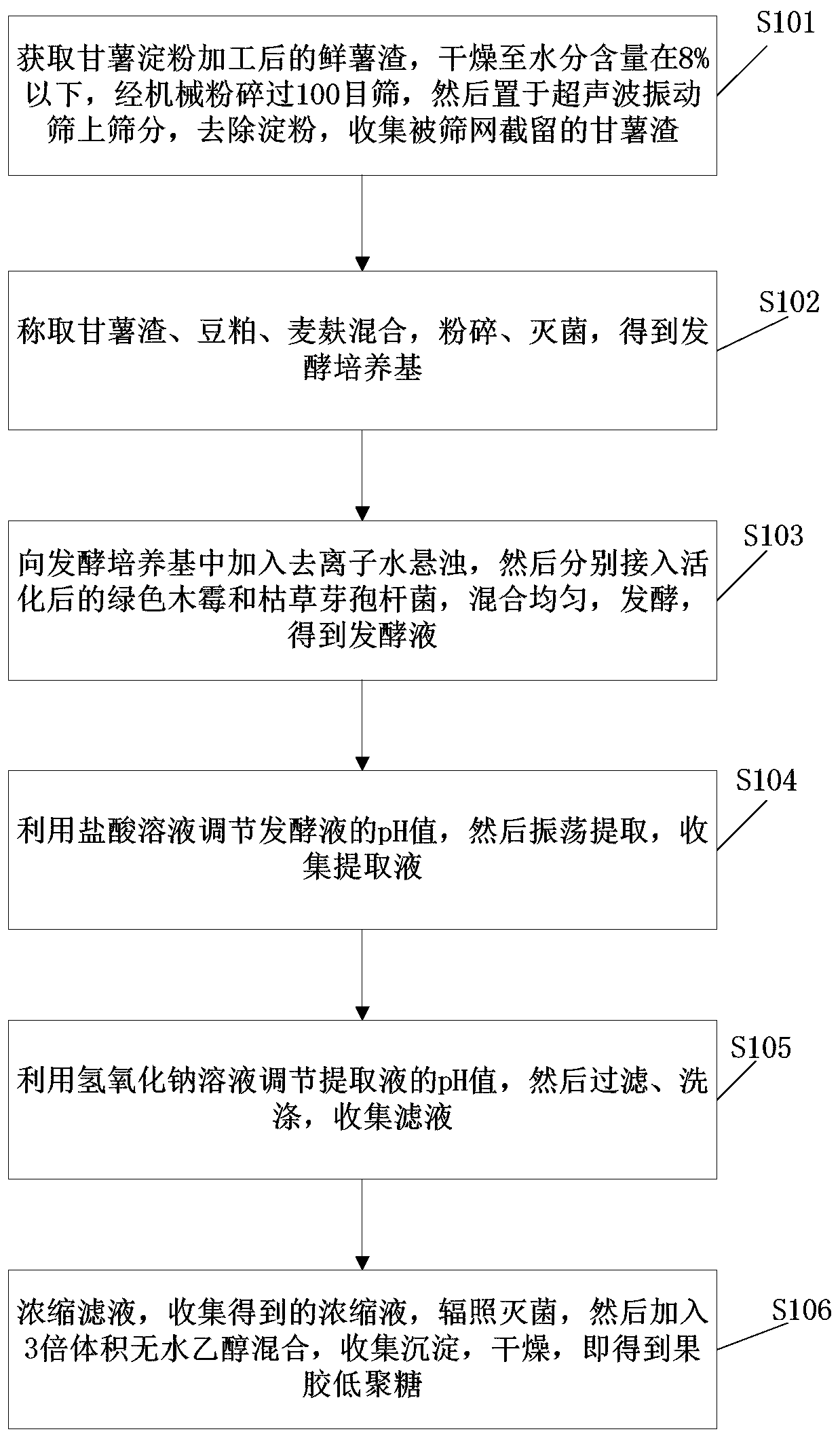

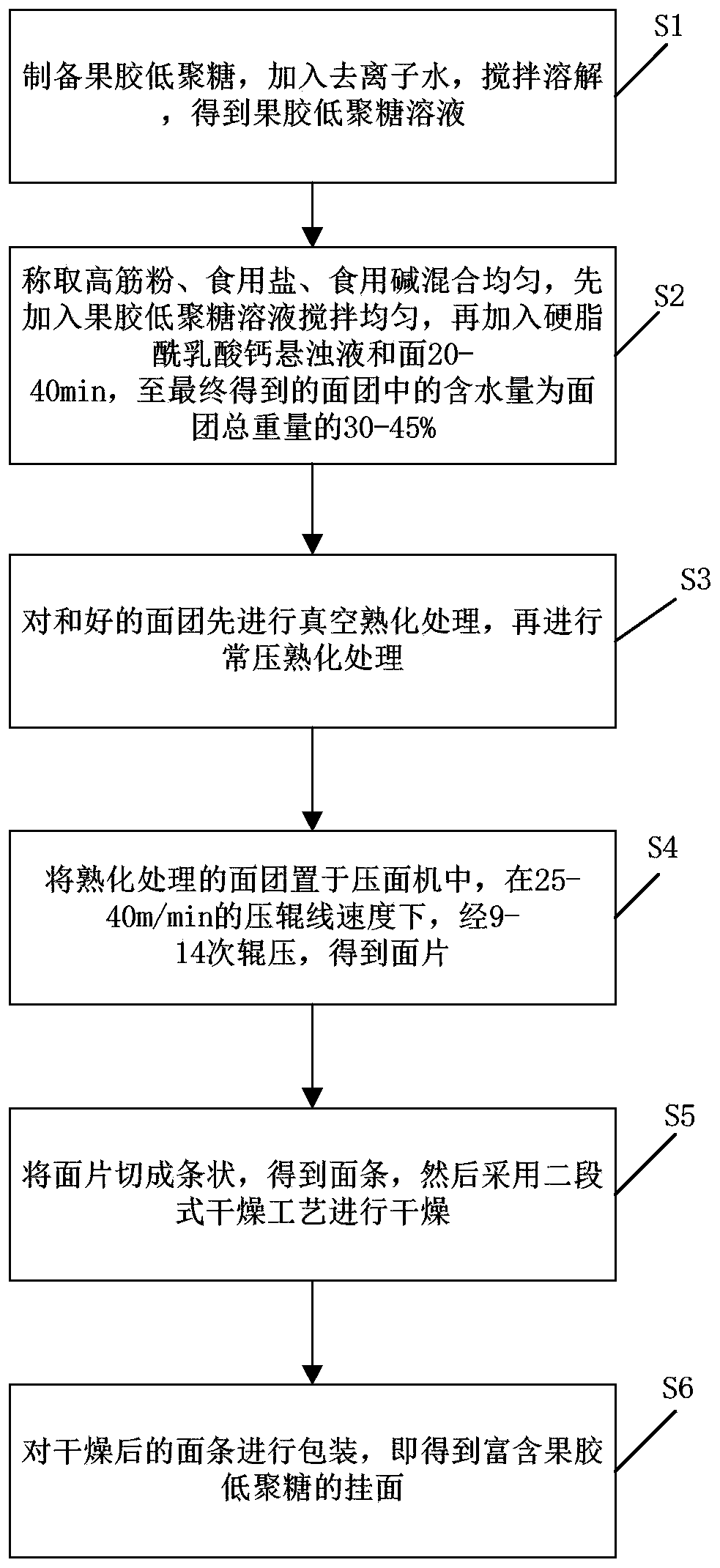

[0051] refer to figure 2 , the embodiment of the present invention also provides a kind of preparation method that is rich in pectin oligosaccharides dried noodle, comprises the following steps:

[0052] Step S1, after mixing the prepared pectin oligosaccharides with deionized water, fully stir and dissolve to form a pectin oligosaccharide solution at 30°C;

[0053] Step S2: Weigh high-gluten flour, edible salt, and edible alkali and mix evenly, first add pectin oligosaccharide solution at 30°C and stir evenly, then add calcium stearoyl lactylate suspension at 30°C and noodles for 20-40min, The water content in the finally obtained dough is 30-45% of the total weight of the dough; the calcium stearoyl lactylate suspension is obtained by mixing the calcium stearoyl lactylate with deionized water and fully stirring at 30°C; wherein, Based on the weight of high-gluten flour, the added amounts of edible salt, edible alkali, pectin oligosaccharides, and calcium stearoyl lactylate...

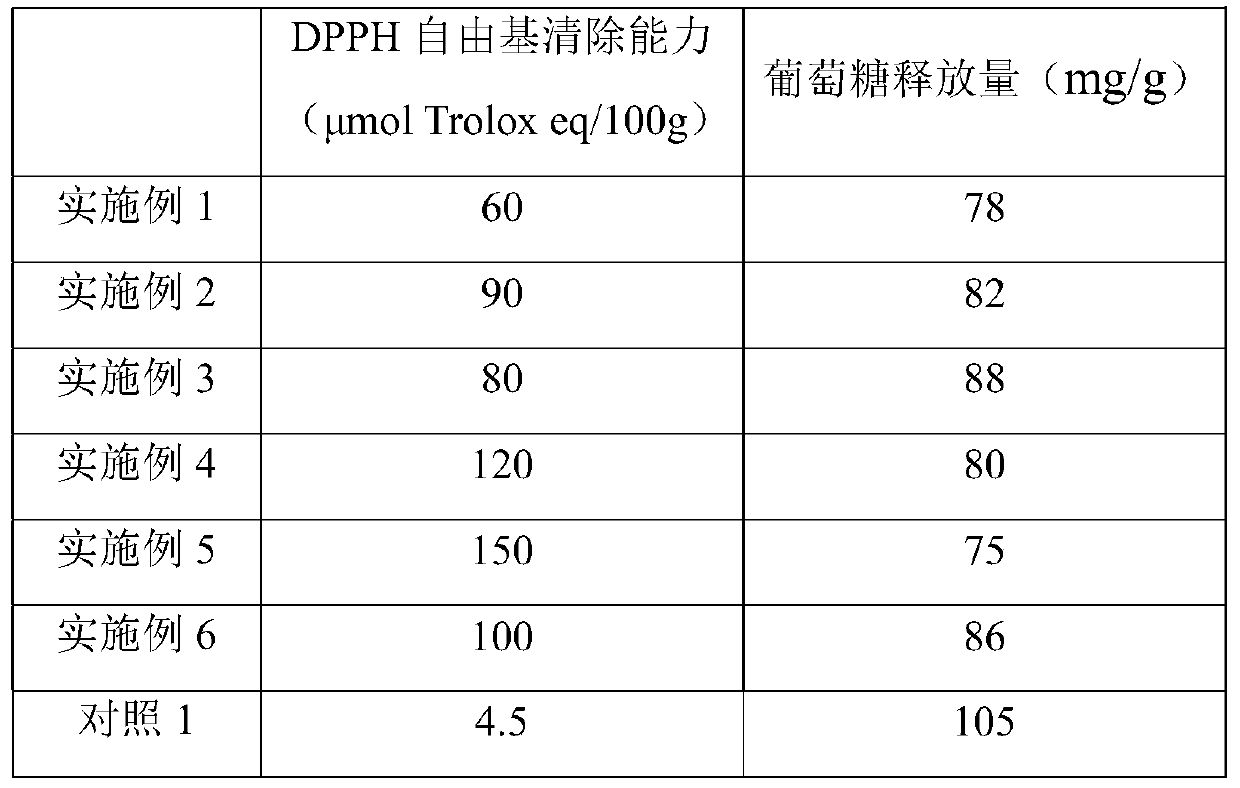

Embodiment 1

[0061] Preparation of pectin oligosaccharides:

[0062] Dry the fresh potato dregs after sweet potato starch processing to a moisture content below 8%, mechanically crush them through a 100-mesh sieve, and then sieve them on an ultrasonic vibrating sieve to remove the starch and collect the sweet potato dregs intercepted by the screen. The ultrasonic power is 100W, the rotating speed of the vibrating screen is 30r / min, and the aperture of the mesh screen is 100μm;

[0063] In parts by weight, take 100 parts of sweet potato dregs after sieving and interception, fully mix them with 10 parts of soybean meal and 6 parts of wheat bran, ultrafinely pulverize them to a particle size of 25 μm, and sterilize at 121 ° C for 20 minutes to obtain the fermented Culture medium;

[0064] According to the weight volume ratio of 1:1.5, the fermentation medium was suspended with deionized water, and then the activated Trichoderma viride and Bacillus subtilis were added according to the inoculu...

Embodiment 2

[0077] Preparation of pectin oligosaccharides:

[0078] Dry the fresh potato dregs after sweet potato starch processing to a moisture content below 8%, mechanically crush them through a 100-mesh sieve, and then sieve them on an ultrasonic vibrating sieve to remove the starch and collect the sweet potato dregs intercepted by the screen. The ultrasonic power is 150W, the rotating speed of the vibrating screen is 20r / min, and the aperture of the mesh screen is 80μm;

[0079] In parts by weight, take 90 parts of sweet potato dregs that have been sieved and intercepted, fully mix them with 12 parts of soybean meal and 8 parts of wheat bran, ultrafinely pulverize them to a particle size of 30 μm, and sterilize at 121°C for 25 minutes to obtain the fermented Culture medium;

[0080] According to the weight volume ratio of 1:2.0, the fermentation medium was suspended with deionized water, and then the activated Trichoderma viride and Bacillus subtilis were added according to the inoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com