Fermented garlic paste and preparation method thereof

A technology for fermenting garlic and garlic sauce, which is applied in food science, food preservation, application, etc., can solve the problems of undiscovered patent publications, loss of garlic nutrients, and reduction of food health care, so as to enhance food health care and shorten production time. cycle, the effect of promoting absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

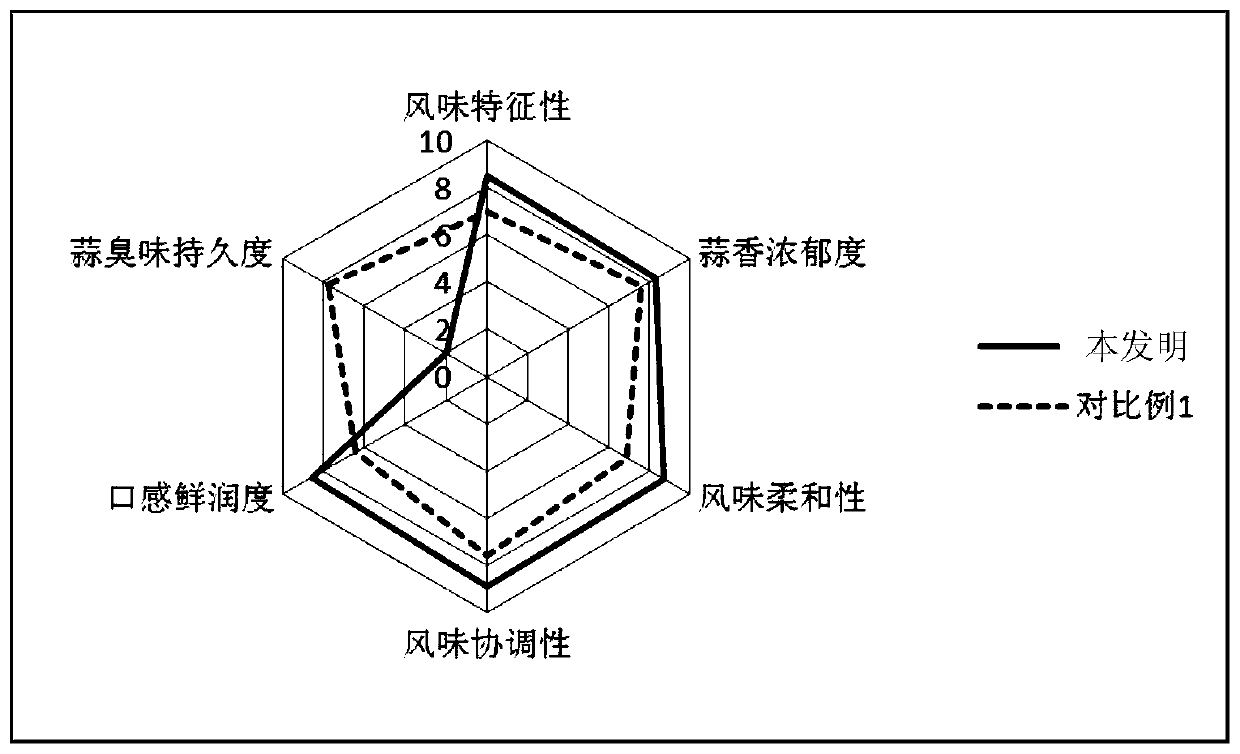

Image

Examples

Embodiment 1

[0032] A kind of fermented garlic paste, its composition and parts by weight are as follows:

[0033] 100 parts of fermented garlic, 4 parts of monosodium glutamate, 6 parts of white sugar, 2 parts of sodium gluconate, 1.5 parts of chicken stock powder, 0.8 parts of molasses, and 0.3 parts of sodium dehydroacetate.

[0034] Wherein, the composition also includes chili oil.

[0035] Wherein, the sodium gluconate is food grade sodium gluconate.

[0036] Wherein, the preparation steps of described fermented garlic are as follows:

[0037] ⑴ Pickling:

[0038] Take fresh garlic, store it at 0-10°C for 15 days, peel the garlic, wash it with water, and dry it for later use;

[0039] After cleaning and dicing the apples, beat them, then add vinegar, rock sugar, and yeast, and place them in an altar for 3-4 days to obtain a pickling solution; wherein, the mass ratio of apple: vinegar: rock sugar: yeast is 5: 5:2:1;

[0040] Soak the processed garlic in the pickling solution, and ...

Embodiment 2

[0049] A kind of fermented garlic paste, its composition and parts by weight are as follows:

[0050] 100 parts of fermented garlic, 3-5 parts of monosodium glutamate, 5-8 parts of white sugar, 1-3 parts of sodium gluconate, 1-2 parts of chicken stock powder, 0.5-1 part of molasses, and 0.1-0.5 parts of sodium dehydroacetate.

[0051] Preferably, the composition also includes chili oil.

[0052] Preferably, the sodium gluconate is food grade sodium gluconate.

[0053] Preferably, the preparation steps of the fermented garlic are as follows:

[0054] ⑴ Pickling:

[0055]Take fresh garlic, store it at 0-10°C for 15 days, peel the garlic, wash it with water, and dry it for later use;

[0056] After cleaning and dicing the apples, beat them, then add vinegar, rock sugar, and yeast, and place them in an altar for 3-4 days to obtain a pickling solution; wherein, the mass ratio of apple: vinegar: rock sugar: yeast is 5: 5:2:1;

[0057] Soak the processed garlic in the pickling s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com