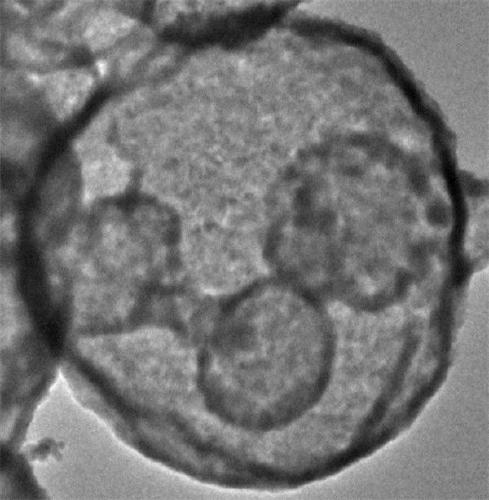

Preparation method of lanthanum carbonate micro-nano material with multi-core nested structure

A technology of nested structure and lanthanum carbonate, which is applied in the field of preparation of lanthanum carbonate micro-nano materials, can solve the problems of complex structure and difficult control of multi-core nested lanthanum carbonate micro-nano materials, and achieve mild conditions, large specific surface area, and reaction low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Step S1: Dissolve 4 g of galactose in 30 mL of secondary water, and stir magnetically for 20 min to form a solution;

[0015] Step S2: Dissolve 0.01 mol of lanthanum chloride in 20 mL of secondary water, stir magnetically for 20 minutes, then add to the solution obtained in step S1, and stir magnetically for 10 minutes;

[0016] Step S3: Add 0.1 g of urea to the solution obtained in Step S2, stir magnetically for 30 min, then sonicate for 10 min, transfer to a 100 mL polytetrafluoroethylene reactor, raise the temperature to 180 °C at a heating rate of 5 °C / min and keep it for 12 h, then Naturally cooled to room temperature, centrifuged and washed, dried at 80°C for 12 hours to obtain a complex of carbon spheres and lanthanum ions;

[0017] Step S4: After grinding the composite of carbon spheres and lanthanum ions obtained in step S3, heat up to 500°C for 3 hours at a heating rate of 1°C / min and calcinate in an air atmosphere, and then cool naturally to room temperature ...

Embodiment 2

[0020] Step S1: Dissolve 5 g of galactose in 30 mL of secondary water, and stir magnetically for 20 minutes to form a solution;

[0021] Step S2: Dissolve 0.02 mol of lanthanum chloride in 20 mL of secondary water, stir magnetically for 20 minutes, then add to the solution obtained in step S1, and stir magnetically for 10 minutes;

[0022] Step S3: Add 0.2 g of urea to the solution obtained in Step S2, stir magnetically for 30 min, then sonicate for 10 min, transfer to a 100 mL polytetrafluoroethylene reactor, raise the temperature to 180 °C at a heating rate of 5 °C / min and keep it for 12 h, then Naturally cooled to room temperature, centrifuged and washed, dried at 80°C for 12 hours to obtain a complex of carbon spheres and lanthanum ions;

[0023] Step S4: After grinding the composite of carbon spheres and lanthanum ions obtained in step S3, heat up to 500°C for 3 hours at a heating rate of 1°C / min and calcinate in an air atmosphere, and then cool naturally to room temperat...

Embodiment 3

[0025] Step S1: Dissolve 4 g of lactose in 30 mL of secondary water, and stir magnetically for 20 min to form a solution;

[0026] Step S2: Dissolve 0.02 mol of lanthanum chloride in 20 mL of secondary water, stir magnetically for 20 minutes, then add to the solution obtained in step S1, and stir magnetically for 10 minutes;

[0027] Step S3: Add 0.4 g of urea to the solution obtained in Step S2, stir magnetically for 30 min, then sonicate for 10 min, transfer to a 100 mL polytetrafluoroethylene reactor, raise the temperature to 180 °C at a heating rate of 5 °C / min and keep it for 13 h, then Naturally cooled to room temperature, centrifuged and washed, dried at 80°C for 12 hours to obtain a complex of carbon spheres and lanthanum ions;

[0028] Step S4: After grinding the composite of carbon spheres and lanthanum ions obtained in step S3, heat up to 500°C for 3 hours at a heating rate of 3°C / min and calcinate in an air atmosphere, and then cool naturally to room temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com