Ammonium nitrate composite antiknock agent, high nitrogen nitro compound fertilizer and preparation method of high nitrogen nitro compound fertilizer

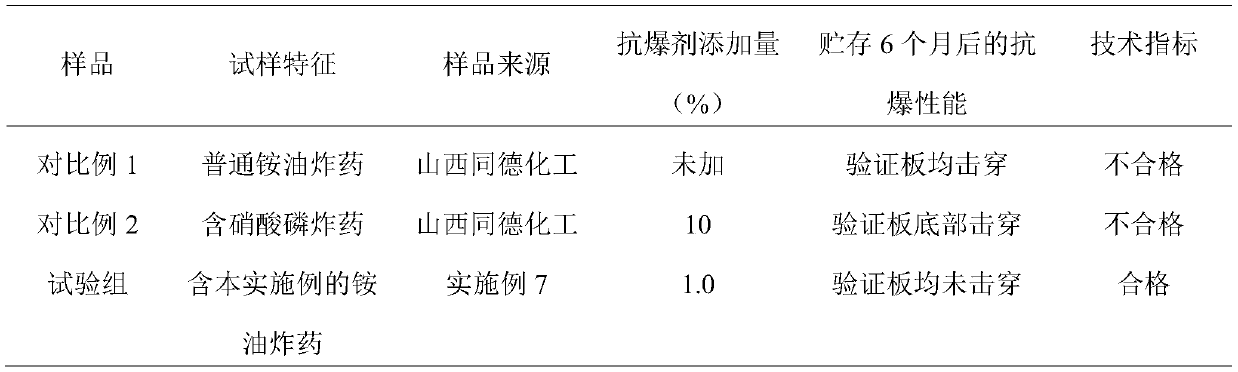

A technology of ammonium nitrate and antiknock agent, which is applied in ammonium nitrate fertilizer, nitrogen fertilizer, fertilization device and other directions, can solve the problems of low particle strength of products, large amount of antiknock agent added, and unstable antiknock performance, etc., and achieve stable antiknock performance. The effect of explosive performance, obvious effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

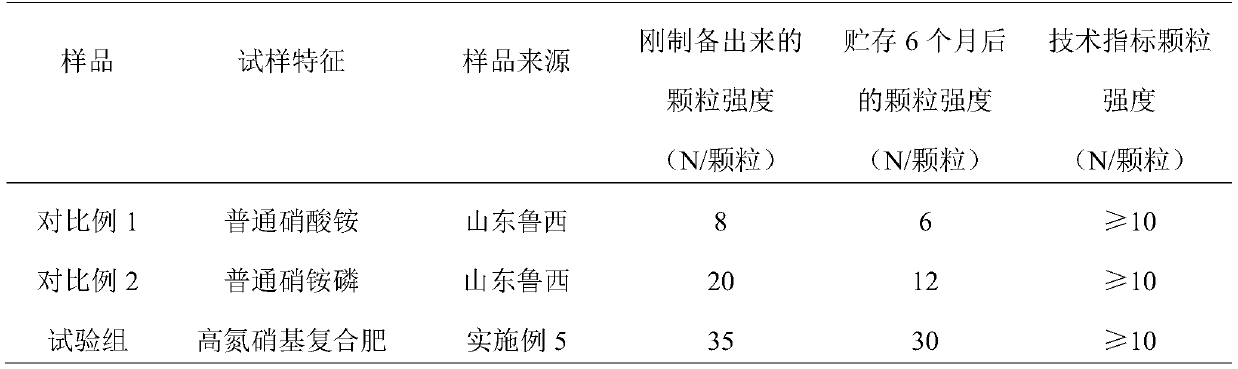

[0021] The above-mentioned ammonium nitrate composite antiknock agent is used in ammonium nitrate fertilizer to prepare high-nitrogen nitro compound fertilizer, which includes 98.5-99% of ammonium nitrate and 1-1.5% of the above-mentioned ammonium nitrate composite antiknock agent. The preparation method of the high-nitrogen nitro compound fertilizer comprises the following steps: in the mixing tank of the ammonium nitrate production line, inject molten ammonium nitrate mother liquor, then add powdered ammonium nitrate composite anti-knock agent and mix, and open the mixing tank after mixing evenly The tanks are all poured, and the granular high-nitrogen nitro compound fertilizer is produced by continuous granulation through the rotary nozzle. The invention increases the particle strength of the product through physical eutectic, and the particle strength of the obtained product is greater than 30N. Through the principle of physical eutectic enhanced passivation and intermolecu...

Embodiment 1

[0024] The ammonium nitrate composite antiknock agent comprises the following components in mass percentage: 60% of ammonium chloride, 20% of aluminum sulfate, 10% of melamine, and 10% of sodium methylene bis-naphthalenesulfonate. During preparation, first bake 5kg of sodium methylene bis-naphthalene sulfonate in an oven at 90°C for 4 hours, and grind 10kg of aluminum sulfate and 30kg of ammonium chloride in a ball mill with a speed of 40r / min to a particle size of 425μm. The particles reach more than 80%; then add the above three qualified raw materials together with 5kg of melamine into a mixer with double-layer helical structure, mix for 30 minutes, and discharge to obtain the ammonium nitrate composite antiknock agent.

[0025] High-nitrogen nitro compound fertilizer, including 98.5% ammonium nitrate and 1.5% of the above-mentioned ammonium nitrate composite antiknock agent, the specific preparation method is: first, inject molten ammonium nitrate into the mixing tank of th...

Embodiment 2

[0027] The ammonium nitrate composite antiknock agent comprises the following components in mass percentage: 85% of ammonium chloride, 10% of aluminum sulfate, 2% of melamine, and 3% of sodium methylene bis-naphthalenesulfonate. During preparation, first bake 5kg of sodium methylene bis-naphthalene sulfonate in an oven at 100°C for 4 hours, and grind 16.6kg of aluminum sulfate and 141.7kg of ammonium chloride in a ball mill with a speed of 40r / min to a particle size of The particle size of 425 μm is more than 80%; then, add the above three qualified raw materials together with 7.5kg melamine into a mixer with double-layer helical structure, mix for 40 minutes, and discharge the material to obtain the ammonium nitrate composite antiknock agent.

[0028] High-nitrogen nitro compound fertilizer, including 99% ammonium nitrate and 1% of the above-mentioned ammonium nitrate composite antiknock agent, the specific preparation method is: first, inject molten ammonium nitrate into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com