Degradable non-woven material used for desertification control and preparation method of degradable non-woven material

A non-woven material and desert control technology, which is applied in the field of preparation of degradable non-woven tubular materials, can solve the problems that the water-absorbing resin cannot fully utilize the water retention and water release functions, it is difficult to realize the desert windproof and sand-fixing effect, and the root system of vegetation cannot go deep into the desert, etc. , to achieve the effect of excellent coating and aggregation, low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

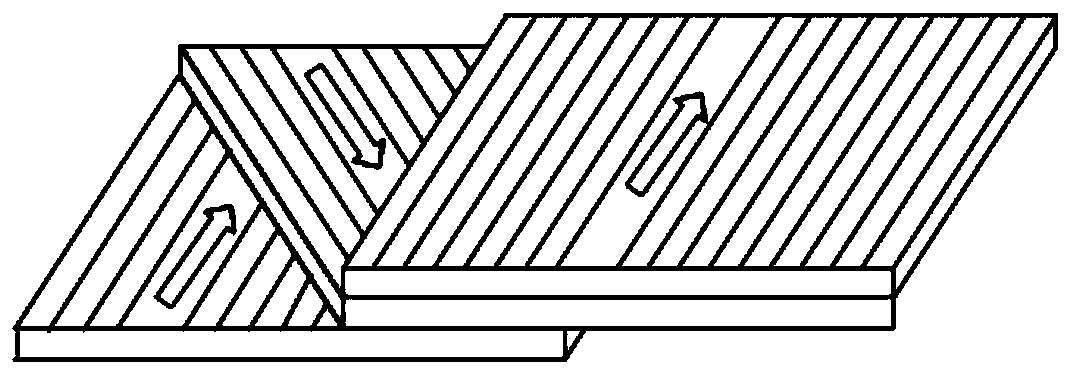

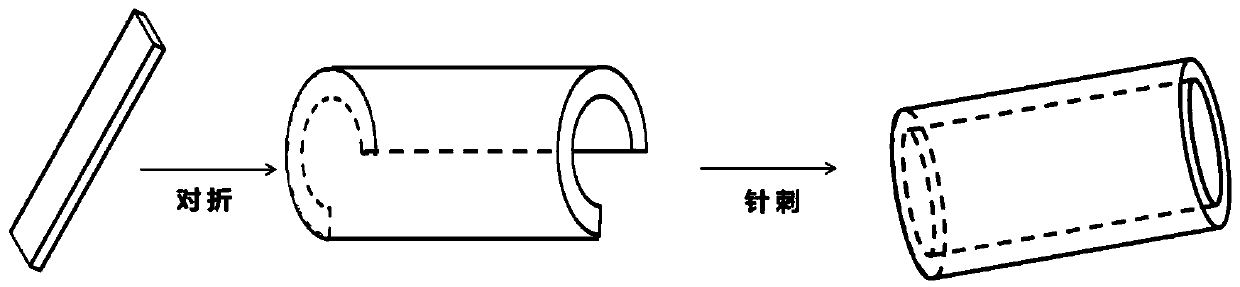

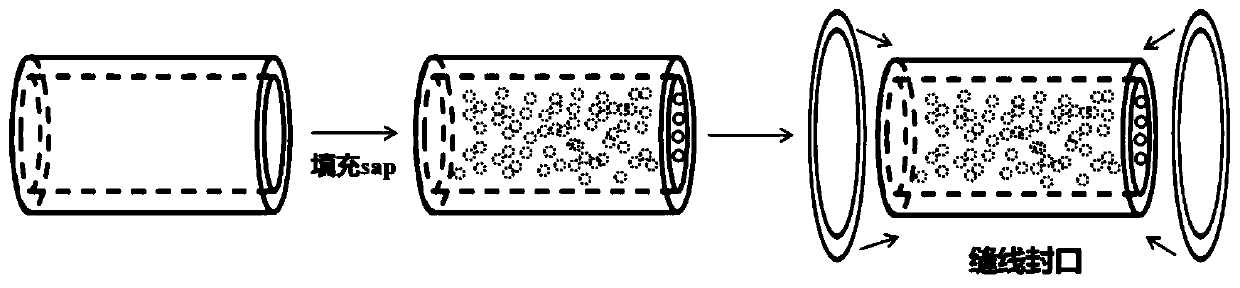

[0029] A degradable non-woven material for desert control, the non-woven material 1 is a tubular structure filled with biodegradable superabsorbent resin 2, and drought-resistant plant seeds 3 are spread on the non-woven material 1, using When buried in the sand, the depth can be planted and cultivated in 4-5 cm (such as Figure 6 shown). Described non-woven material adopts eco-environmental protection material polylactic acid fiber cross-laying to make (such as figure 1 shown). The biodegradable superabsorbent resin is a cross-linked product of starch grafted with potassium salt of acrylate. The biodegradable superabsorbent resin must be soaked in water for more than 24 hours to absorb water, and the water retention period is two months.

[0030] The preparation method of the above-mentioned degradable nonwoven material is characterized in that it comprises the following steps:

[0031] Step 1): Polylactic acid fibers are formed into a web and then cross-laid to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com