Pressure sensor and preparation method and use thereof

A pressure sensor and electrode layer technology, applied in the field of sensors, can solve the problems of not paying attention to the optical transparency of sensors, achieve good optical transparency and flexibility, improve sensitivity, and improve transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment prepares the pressure sensor according to the following method:

[0058] (1) Mix and stir cellulose acetate and 1-ethyl-3-methylimidazolium hexafluorophosphate with a mass ratio of 1:1, and dry at 80°C to form a film to obtain a highly transparent dielectric layer.

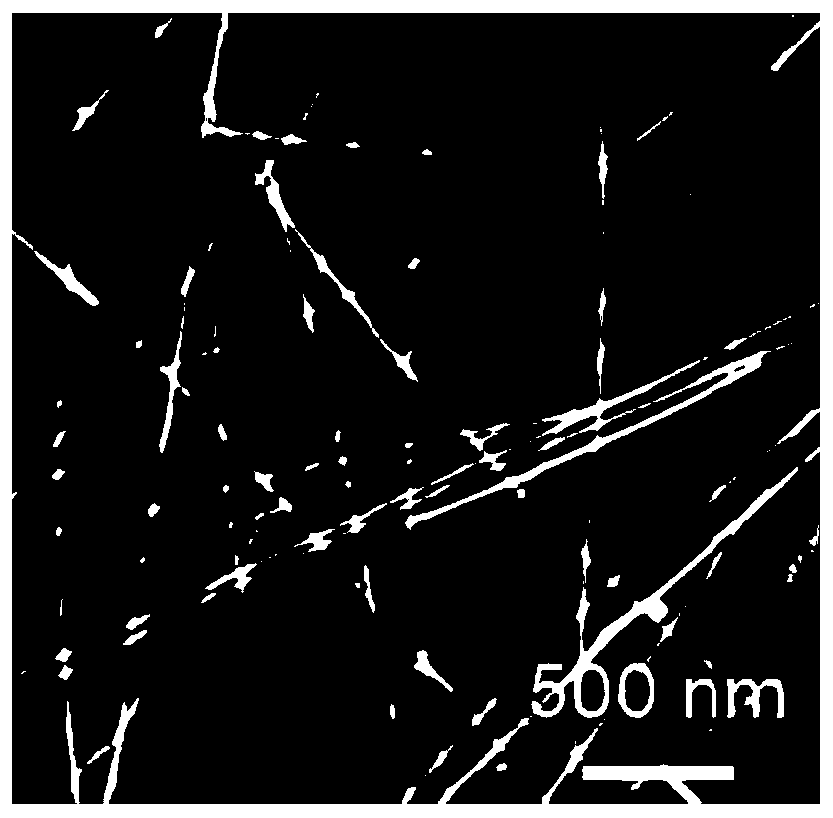

[0059] (2) Coating a layer of metallic silver nanowires on one side of the transparent polyimide film by scraping the film to obtain a transparent electrode layer.

[0060] (3) The transparent dielectric layer obtained in step 1 is sandwiched between two transparent electrode layers obtained in step 2, and the surroundings are fixed with epoxy resin to obtain a flexible transparent high-sensitivity pressure sensor.

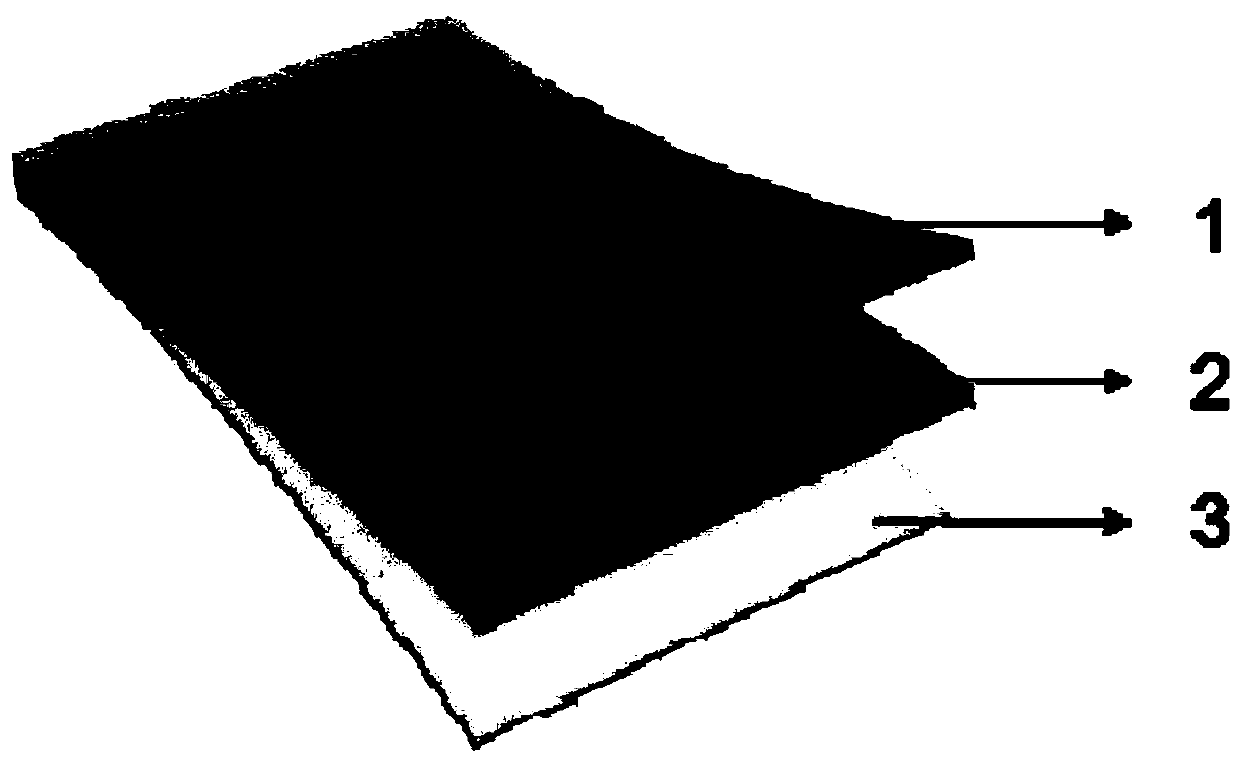

[0061] The pressure sensor prepared in this embodiment is composed of a dielectric layer and a first electrode layer and a second electrode layer respectively located on both sides of the dielectric layer. The dielectric layer includes an ion active material and a membrane mater...

Embodiment 2

[0069] This embodiment prepares the pressure sensor according to the following method:

[0070] (1) The polymethyl methacrylate and ion gel with a mass ratio of 1:2 were shaken and mixed evenly, and pressed at 80°C to form a film to obtain a highly transparent dielectric layer.

[0071] (2) Coating a layer of metallic gold nanowires on one side of the transparent polyester film by scraping the film to obtain a transparent electrode layer.

[0072] (3) The transparent dielectric layer obtained in step 1 is sandwiched between two transparent electrode layers obtained in step 2, and the surroundings are fixed with butyl rubber to obtain a flexible transparent high-sensitivity pressure sensor.

[0073] The pressure sensor prepared in this embodiment is composed of a dielectric layer and a first electrode layer and a second electrode layer respectively located on both sides of the dielectric layer. The dielectric layer includes an ion active material and a membrane material, and th...

Embodiment 3

[0076] This embodiment prepares the pressure sensor according to the following method:

[0077] (1) Mix polylactic acid with a mass ratio of 1:3 and 1-ethyl-3-methylimidazolium phosphate dimethyl salt evenly, press at 150°C to form a film, and obtain a highly transparent dielectric layer.

[0078] (2) Coating a layer of metal copper nanowires on one side of the transparent polyethylene film by scraping the film to obtain a transparent electrode layer.

[0079](3) Sandwich the transparent dielectric layer obtained in step 1 between two transparent electrode layers obtained in step 2, and fix it with scotch tape around to obtain a flexible transparent high-sensitivity pressure sensor.

[0080] The pressure sensor prepared in this embodiment is composed of a dielectric layer and a first electrode layer and a second electrode layer respectively located on both sides of the dielectric layer. The dielectric layer includes an ion active material and a membrane material, and the ion a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com