Hard composite insulator and preparation method thereof

A composite insulator and hard technology, applied in the field of electrical insulation equipment, can solve the problems of surface hydrophobicity, physical and mechanical properties, electrical performance attenuation, reduced creepage distance, inability to detect, etc., to improve the ability to resist bird peck damage, prevent The effect of brittle fracture accident and easy construction and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the modified silicone rubber is obtained by injecting raw materials into a mold and plasticizing at a certain temperature and pressure.

[0052] Furthermore, on the premise of not affecting the properties of the modified silicone rubber, compatibilizers, reinforcing agents, and vulcanizing agents can be added during the preparation of the modified silicone rubber to improve the performance of the modified silicone rubber.

[0053] Examples of the compatibilizer include vinyltriethoxysilane, silicone oil and the like.

[0054] As examples of the reinforcing agent, silica, carbon black, white carbon black and the like can be cited.

[0055] Examples of vulcanizing agents include, but are not limited to, sulfur-based vulcanizing agents, peroxide vulcanizing agents, and the like.

[0056] plastic

[0057] The plastic is not particularly limited.

[0058] Examples of plastics include, but are not limited to, acrylonitrile-butadiene-styrene (ABS),...

Embodiment approach

[0100] As a preferred embodiment, the alumina is α-alumina and / or γ-alumina.

[0101] The α-alumina belongs to the trigonal crystal system, the coordination numbers of the positive and negative ions are 6 and 4 respectively, and the oxygen ions in the structure form a close-packed hexagonal packing, forming multiple octahedral shapes, and the aluminum ions randomly exist in each octahedron. In the voids of the octahedron, since the ratio of aluminum atoms to oxygen atoms is 2:3, aluminum ions cannot fill all the voids of the oxygen ion octahedron, and only fill two-thirds.

[0102] Preferably, the particle size of the α-alumina is 200-500 nm.

[0103] The γ-alumina crystal structure belongs to the defective spinel crystal structure, which has a tetragonal face-centered cubic structure. The 32 cubic oxygen atoms will form 24 gaps, and some aluminum atoms are irregularly distributed in the 24 The unfilled voids will cause the crystal structure of γ-alumina to change.

[0104] ...

Embodiment 1

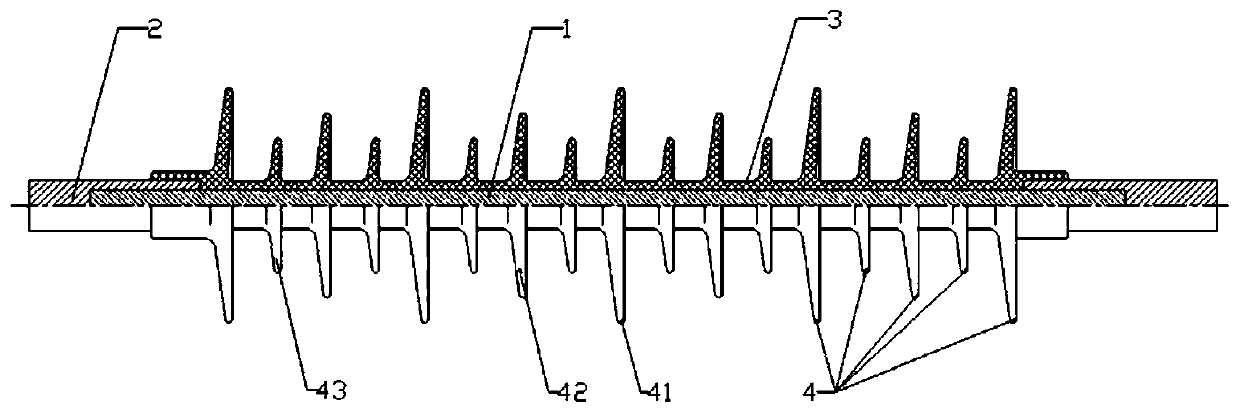

[0157] Such as figure 1 As shown, a rigid composite insulator includes an insulating mandrel 1, fittings 2, a hard sheath 3, and a hard shed 4. The fittings 2 are arranged at both ends of the insulating mandrel 1; the hard sheath 3 covers the outer surface of the insulating mandrel 1 and extends to the surface of the fitting 2 to form a seal; the hard shed 4 is arranged on the On hard sheath 3;

[0158] The hard umbrella skirt includes more than one large umbrella-shaped protrusions 41 arranged coaxially with the insulating mandrel, and the diameters of the large umbrella-shaped protrusions 41 are the same;

[0159] A small umbrella-shaped protrusion 43 , a middle umbrella-shaped protrusion 42 , and a small umbrella-shaped protrusion 43 are sequentially arranged between the adjacent large umbrella-shaped protrusions 41 .

[0160] Wherein, the preparation raw materials of the hard shed and the hard sheath are the same, and in parts by weight, they all include 40 parts of poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com