Method and system for multi-wavelength laser time-sharing ablation of solar cell dielectric film

A solar cell and dielectric film technology, which is applied in laser welding equipment, circuits, electrical components, etc., can solve the problems of large thermal influence, serious damage, and increased risk of solar cell cracks, so as to improve processing speed, good ablation ability, The effect of improving efficiency and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

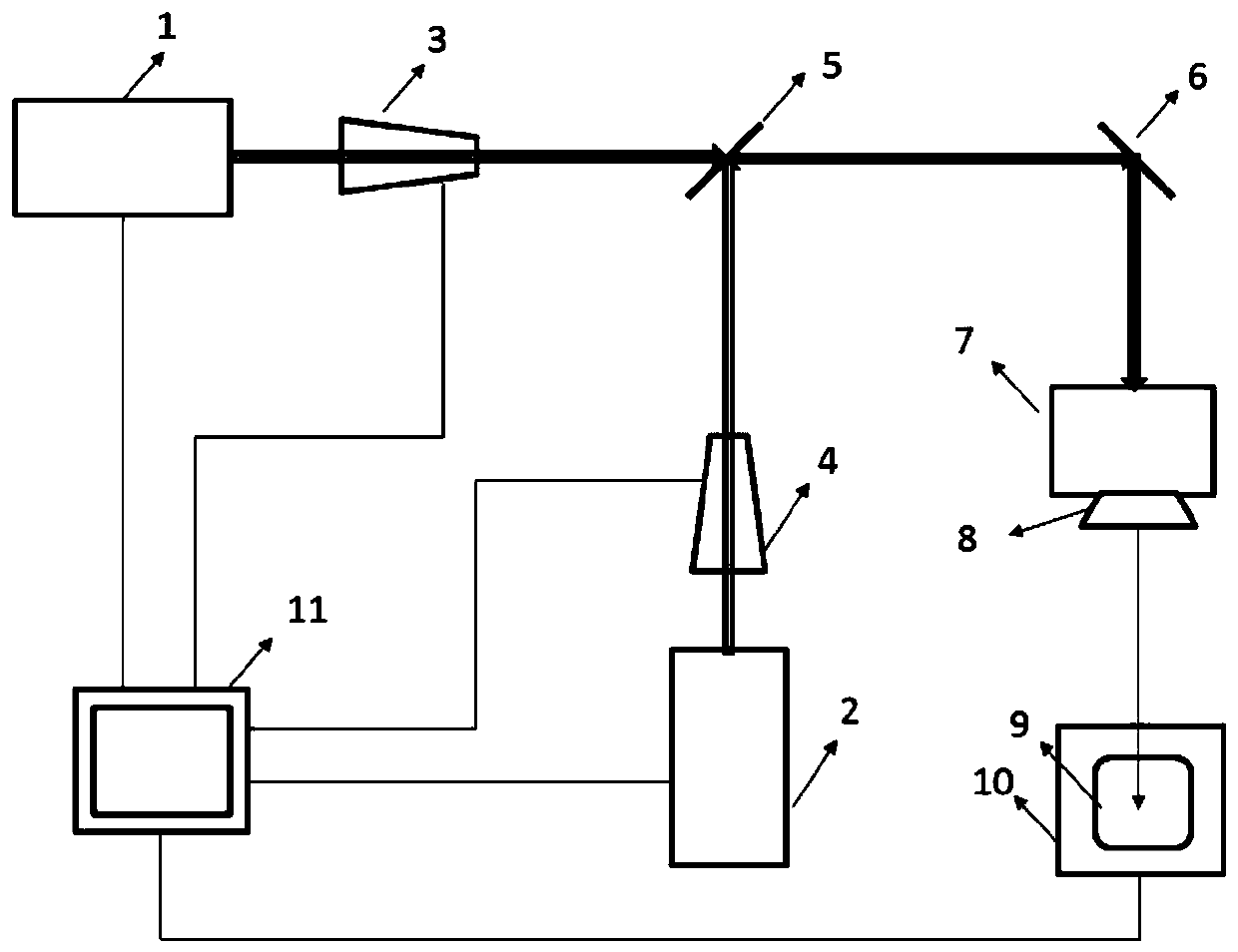

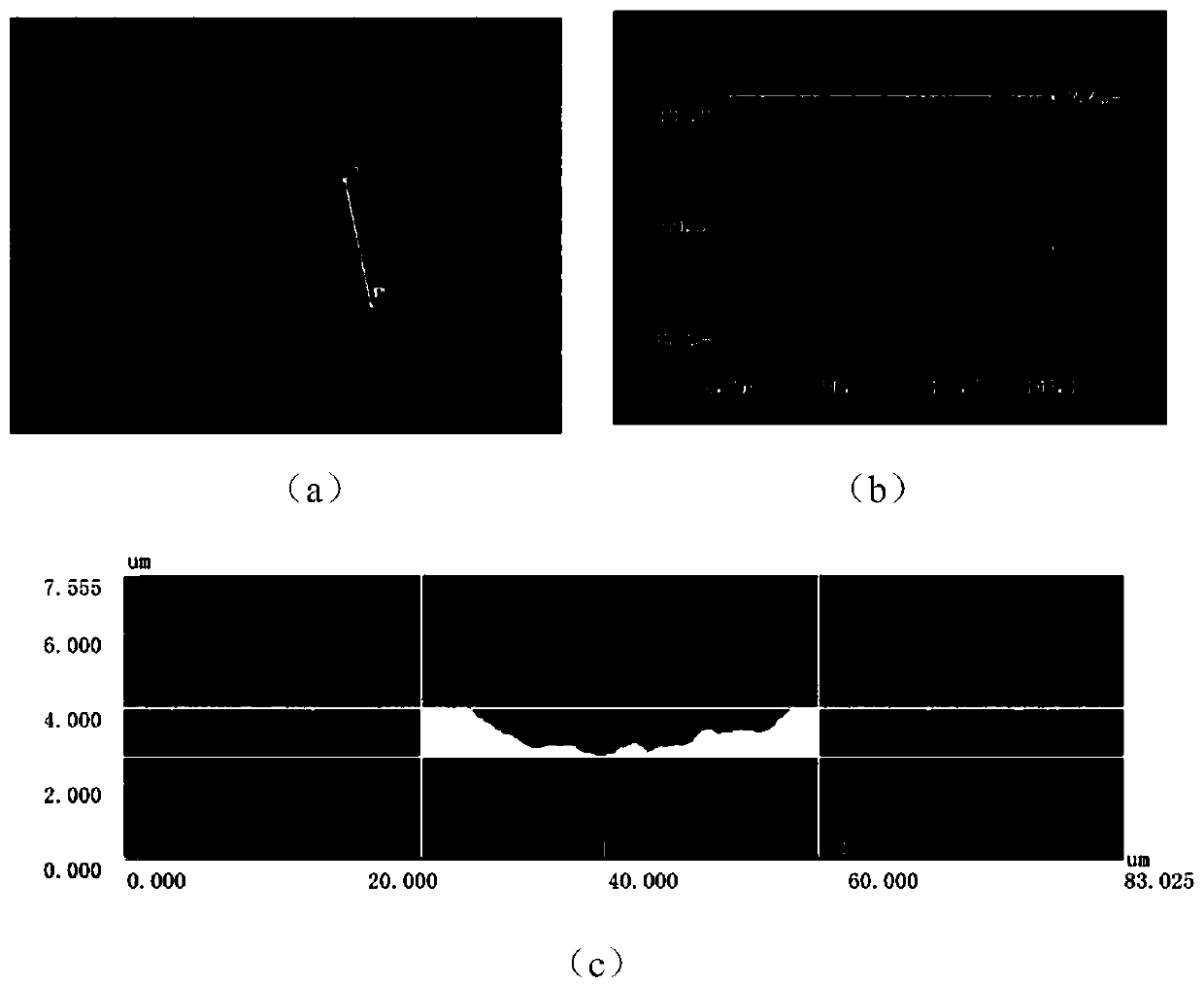

[0043] Embodiment 1 Using the method of the present invention to perform laser ablation on crystalline silicon solar cells, the material of the first layer of the crystalline silicon solar cells in this embodiment is aluminum oxide with a thickness of 10 nm, and the material of the second layer is silicon nitride with a thickness of 150 nm. The wavelength of the first-wavelength laser is 1064nm, the single-point energy is 40μJ, and the spot diameter is 24μm; the wavelength of the second-wavelength laser is 532nm, the single-point energy is 27μJ, and the spot diameter is 33μm. The processing speed is selected as 25m / s, and the time interval between the two lasers is set as 1ns. Facula ablation appearance as Figure 4 As shown, the diameter of the spot is 33 μm, and the depth is 1.51 μm; the comparison shows that the energy of the 1064nm laser is higher than the threshold of the passivation film. Under its synergistic effect, the penetration ability of the 532nm laser is improve...

Embodiment 2

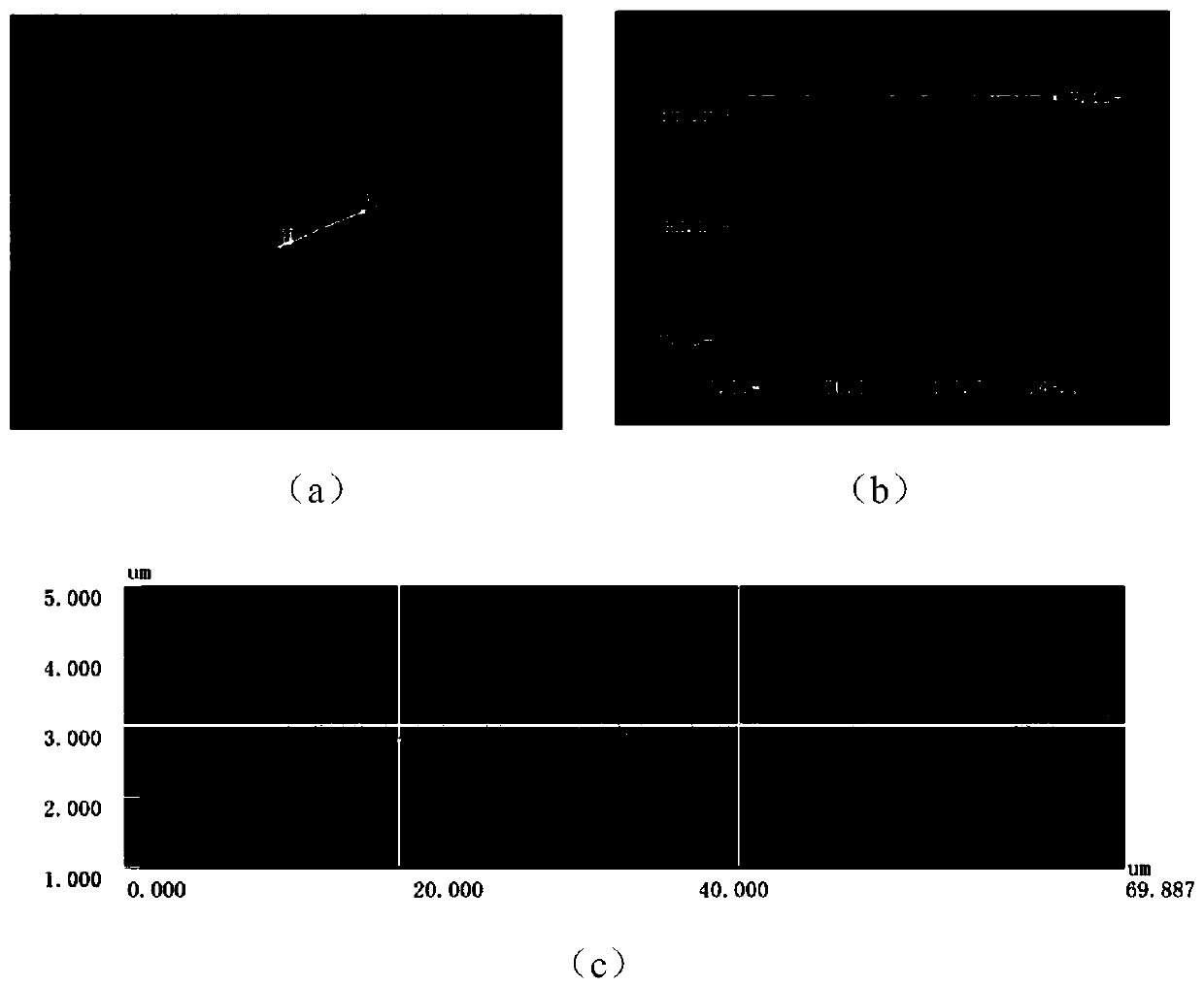

[0044] Embodiment 2 Using the method of the present invention to perform laser ablation on crystalline silicon solar cells, the material of the first layer of the crystalline silicon solar cells in this embodiment is aluminum oxide with a thickness of 10 nm, and the material of the second layer is silicon nitride with a thickness of 150 nm. The wavelength of the first-wavelength laser is 1064nm, the single-point energy is 40μJ, and the spot diameter is 24μm; the wavelength of the second-wavelength laser is 355nm, the single-point energy is 12μJ, and the spot diameter is 38μm. The processing speed is selected to be 25m / s, the time interval between the two lasers is set to 1ns, the final spot diameter is 38μm, and the depth is 0.4μm; the comparison shows that the energy of the 1064nm laser is higher than the threshold of the passivation film. Under its synergy, the 355nm laser The penetration ability is improved, which increases the depth of ablation, which is conducive to improv...

Embodiment 3

[0045] Example 3 Laser ablation of crystalline silicon solar cells is carried out by using the method of the present invention. The material of the first layer of the crystalline silicon solar cells of this embodiment is aluminum oxide with a thickness of 10 nm, and the material of the second layer is silicon nitride with a thickness of 150 nm. The wavelength of the first-wavelength laser is 808nm, the single-point energy is 23μJ, and the spot diameter is 24μm; the wavelength of the second-wavelength laser is 532nm, the single-point energy is 27μJ, and the spot diameter is 33μm. The processing speed is selected as 25m / s, and the time interval between the two lasers is set as 1ns. The final spot diameter is 33 μm, and the depth is 1.45 μm. The comparison shows that the energy of the 808nm laser is higher than the threshold of the passivation film. Under its synergistic effect, the penetration ability of the 532nm laser is improved, which improves the ablation depth, which is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength range | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com