Sulfur-doped MXene composite material as well as preparation method and application thereof

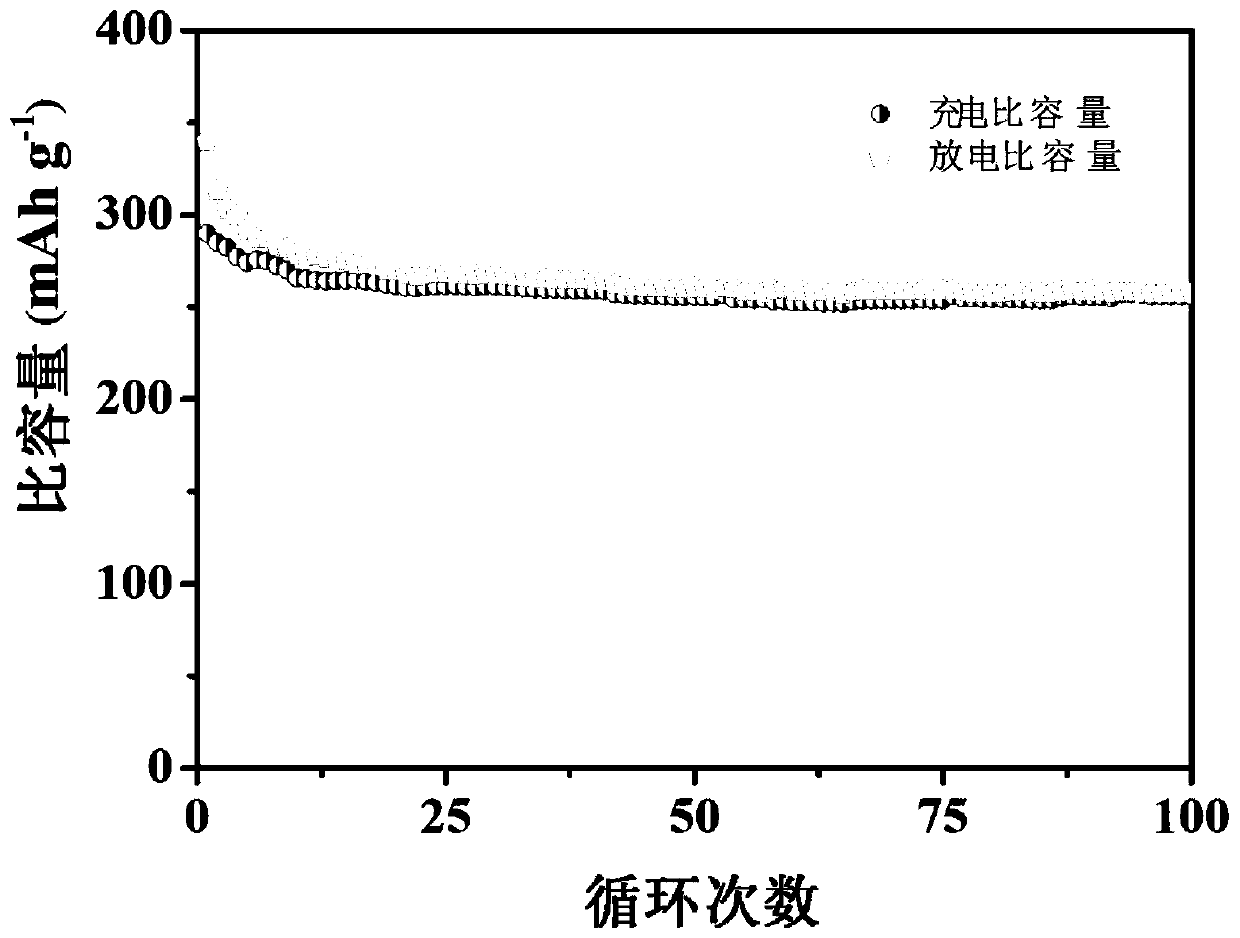

A composite material, sulfur-doped technology, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as unsatisfactory performance, achieve good cycle performance and rate performance, stable cycle performance, embedded / Moderate effect on depotassium potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of sulfur-doped MXene composite material, comprising the following steps:

[0029] (1) Weigh 0.1g of Ti 3 C 2 T x Add 0.1 g of phenylene sulfide into deionized water, heat to 50° C. and magnetically stir for 1 hour to obtain a mixed solution.

[0030] (2) Move the mixed solution to the reactor to seal it, and then place it in an oven, adjust the reaction temperature to 80° C., and the reaction time to 4 hours.

[0031] (3) The obtained product was alternately washed 3 times with deionized water and ethanol, centrifuged at a centrifugal speed of 3000r / min for 2min, and finally put into a vacuum drying oven and dried at 60°C for 8h.

[0032] (4) Potassium ion battery negative electrode preparation: mix the obtained sulfur-doped MXene with polyvinylidene fluoride binder and carbon black in a ratio of 8:1:1 by mass, and add an appropriate amount of N-methylpyrrolidone, After stirring evenly, a slurry is formed and coated on the current collector, an...

Embodiment 2

[0035] A preparation method of sulfur-doped MXene composite material, comprising the following steps:

[0036] (1) Weigh 0.2g of Ti 3 C 2 T x Add 2 g of phenylene sulfide into deionized water, heat to 60° C., and magnetically stir for 3 hours to obtain a mixed solution.

[0037] (2) Move the mixed liquid to the reactor to seal it, and then place it in an oven, adjust the reaction temperature to 160° C., and the reaction time to 18 hours.

[0038] (3) The obtained product was alternately washed 3 times with deionized water and ethanol, centrifuged at a centrifugal speed of 3250r / min for 3min, and finally put into a vacuum drying oven and dried at 60°C for 16h.

[0039] (4) Potassium ion battery negative electrode preparation: mix the obtained sulfur-doped MXene with polyvinylidene fluoride binder and carbon black in a ratio of 8:1:1 by mass, and add an appropriate amount of N-methylpyrrolidone, After stirring evenly, a slurry is formed and coated on the current collector, a...

Embodiment 3

[0042] A preparation method of sulfur-doped MXene composite material, comprising the following steps:

[0043] (1) Weigh 0.5g of Ti 3 C 2 T xAdd 10 g of phenylene sulfide into deionized water, heat to 70° C., and magnetically stir for 5 hours to obtain a mixed solution.

[0044] (2) Move the mixed solution to the reaction kettle to seal it, and then place it in an oven, adjust the reaction temperature to 200° C., and the reaction time to 36 hours.

[0045] (3) The obtained product was alternately washed 3 times with deionized water and ethanol, centrifuged at a centrifugal speed of 3500r / min for 4min, and finally put into a vacuum drying oven and dried at 60°C for 24h.

[0046] (4) Potassium ion battery negative electrode preparation: mix the obtained sulfur-doped MXene with polyvinylidene fluoride binder and carbon black in a ratio of 8:1:1 by mass, and add an appropriate amount of N-methylpyrrolidone, After stirring evenly, a slurry is formed and coated on the current co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com