Preparation method and application of anti-pollution silicon-titanium copolymerized composite membrane

A composite membrane, anti-pollution technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem that the structure of the modifier is difficult to control and characterize, the related mechanism is complex, and it is difficult to achieve effective surface modification of membrane pores. and other problems to achieve the effect of excellent water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

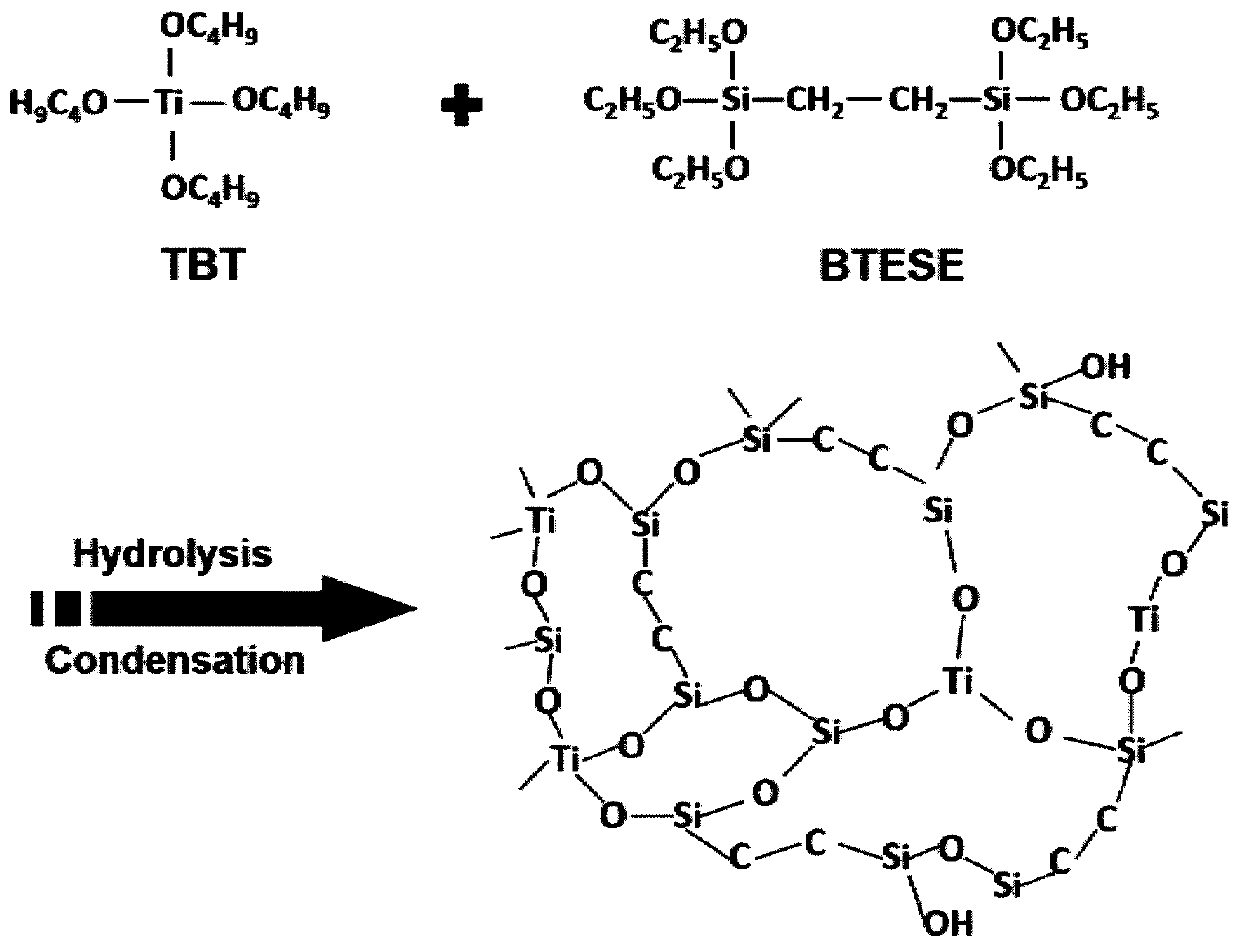

[0024] (1) Preparation of silica-titanium polymerization sol: add 18.973g EtOH to a 100mL beaker, then add 1.000g BTESE and 0.192g TBT and stir for 2 minutes, add 1 to 2 drops of 37wt% concentrated hydrochloric acid in 3.655g water to prepare a hydrochloric acid solution, and then add the hydrochloric acid solution Slowly add it dropwise to the precursor solution, transfer the beaker to a constant temperature water bath at 50°C, continue stirring for 3 hours to obtain a silica-titanium sol and dilute its concentration to 0.5wt% with EtOH;

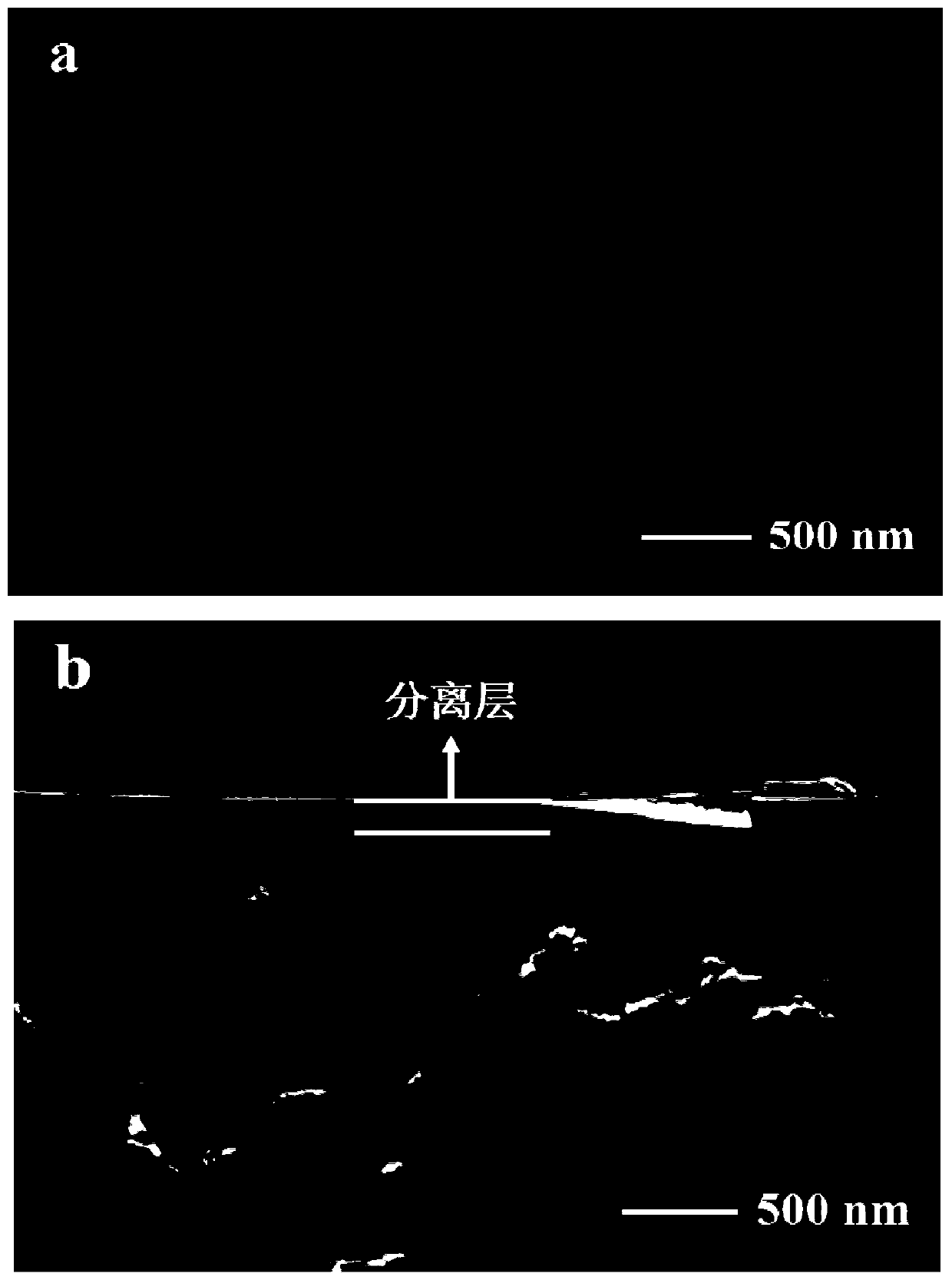

[0025] (2) Coating the silica-titanium sol prepared in step (1) on α-Al by rubbing method 2 O 3 On the sheet membrane, then calcined at 300 ° C for 30 min, repeating the above steps twice to obtain a silicon-titanium copolymer separation membrane;

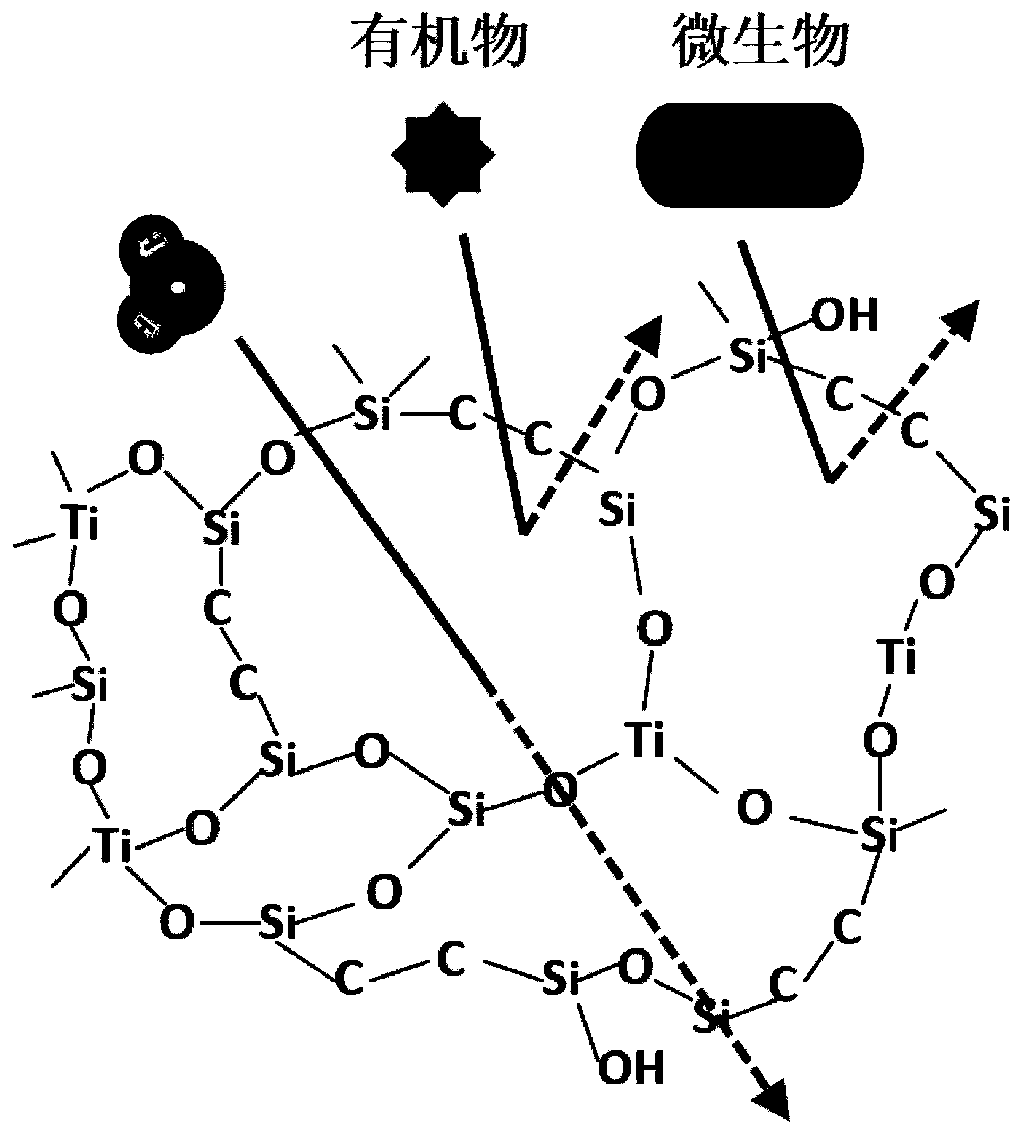

[0026] (3) Use a separation membrane to separate the mixed aqueous solution containing 2000ppm sodium chloride (NaCl) and 800ppm bovine serum albumin (BSA). After running for 1 hour, wash the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com