A hydraulic cavitation device for preparing blended lubricating oil by mixing oil and water

A technology of oil-water mixing and hydraulic cavitation, which is applied to mixers, mixing methods, lubricating compositions, etc., can solve the problems of small processing capacity, low efficiency, and inability to meet the production needs of industrial lubricants, and achieve large processing capacity and increased Yield and the effect of reducing fuel consumption cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

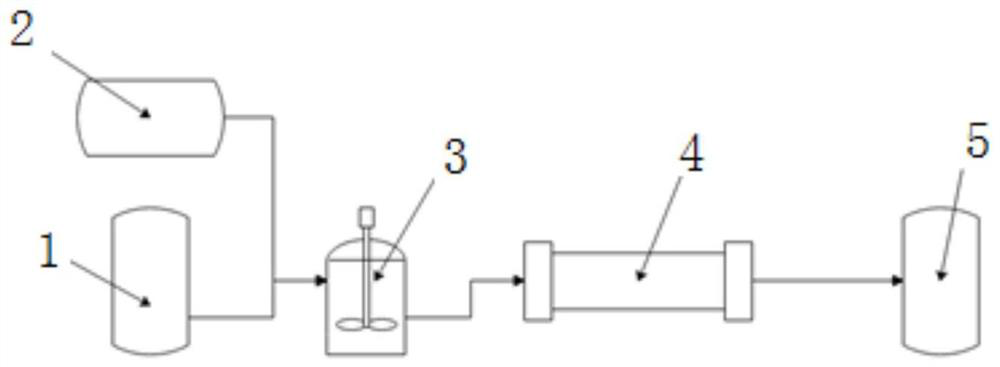

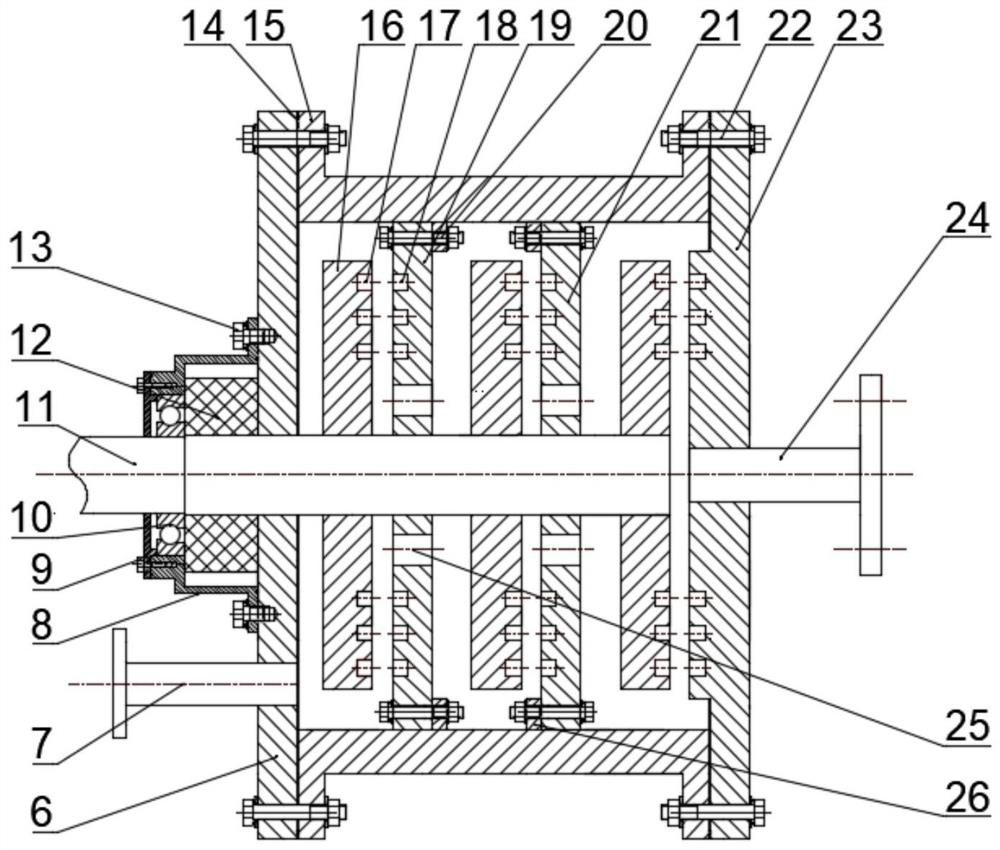

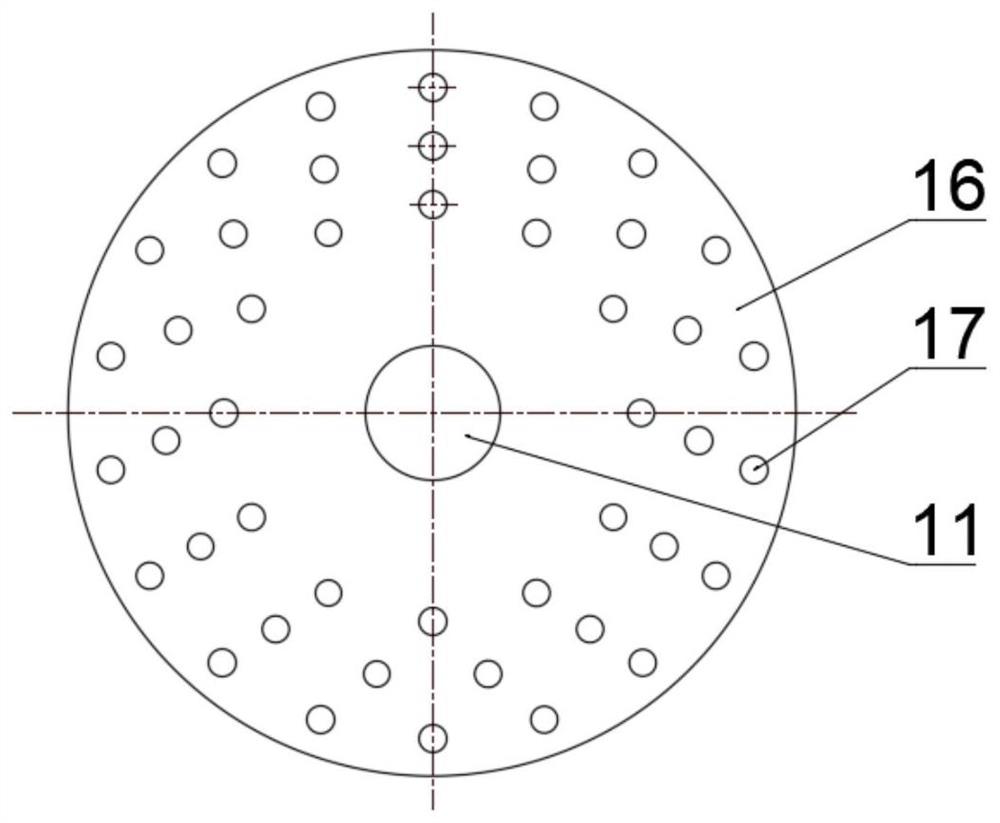

[0028] The hydraulic cavitation device for preparing blended lubricating oil by mixing oil and water of the present invention is used to process oil-water mixture by adopting the principle of hydraulic cavitation to prepare blended lubricating oil. The preparation system of the lubricating oil is as figure 1 As shown, it includes a raw material tank 1 , a liquid storage tank 2 , an agitator 3 , a hydraulic cavitation device 4 and a storage tank 5 . The crude oil is pretreated to obtain base oil, which is stored in the raw material tank 1 . Water and additives are contained in the liquid storage tank 2 . According to a certain ratio, the base oil in the raw material tank 1, the water in the water storage tank 2 and the additives are transported to the agitator 2, and the oil-water mixture is stirred and pretreated, and a rougher mixture is obtained through preliminary shearing, mixing and atomization. The emulsion (with a particle size of about 5 μm), the rough liquid is tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com