Polybenzoxazole-polyparaphenylenebenzodiimidazole O-PBI liquid crystal copolymer and preparation and application thereof

A technology of polybenzoxazole and benzodiimidazole, applied in the direction of single-component synthetic polymer rayon, textiles and papermaking, fiber chemical characteristics, etc., can solve complex process, lack of easy photodegradation performance and improvement, preparation To avoid problems such as long process, achieve good spinnability and heat resistance, facilitate industrialization, and excellent rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The preparation of embodiment 1 compound salt monomer TATAB (1,2,4,5-tetraaminobenzene of terephthalic acid)

[0063]

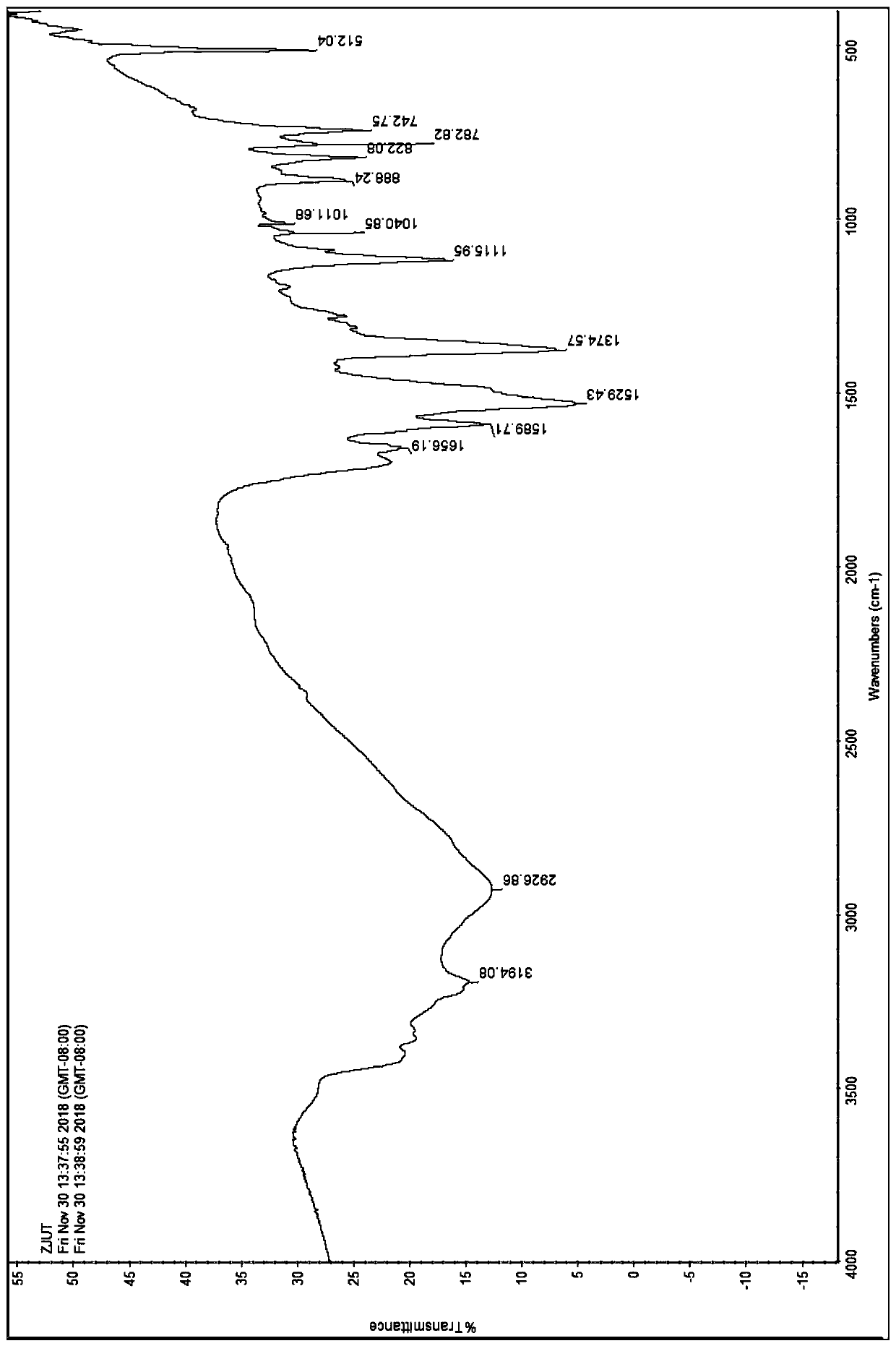

[0064] Add 200g deoxygenated water and 10.697g Na 2 CO 3 (0.1009mol) and 8.384g (0.0504mol) terephthalic acid (TA), stirring and heating up to 70°C until it dissolves into a light brown transparent solution, under the protection of nitrogen, add 14.34g (0.0505mol)1,2, 4,5-Tetraaminobenzene hydrochloride (TABH), after the addition was completed, stirred at 70-80°C for 15 minutes, then slowly cooled to room temperature, filtered, and the wet filter cake was washed with 30mL deoxygenated water, filtered and dried, and vacuum-dried at 70°C to obtain 12.80 g (0.0421 mol) of 1,2,4,5-tetraaminobenzene compound salt (TATAB) of terephthalic acid, the yield as TA is 83.35%. FT-IR (KBr) see attached figure 1 .

Embodiment 2

[0065] Example 2 O 4 -PBI (poly-2,5-benzoxazole-p-phenylenebenzimidazole) and its monofilament fibers

[0066]

[0067] A) poly-2,5-benzoxazole-p-phenylenebenzimidazole (2:1)O 4 -PBI

[0068] Sequentially add P into the glass polymerization reaction column 2 o 5 Mass concentration is 85.3% polyphosphoric acid (PPA) 18.0g and P 2 o 5 3.40g, turn on the spiral stirring, and raise the temperature to 100°C and control the speed of 350r / min to stir for 30min and wait for P 2 o 5 After the reaction was dissolved, pass N 2 Slowly add 2.45g of AHBA and 2.449g of TATAB (mol ratio 2:1, mass ratio 0.50:0.50) in sequence under protection for 3 minutes. After the addition, slowly rise to 172°C with stirring for 60 minutes. Light purple fluorescence appears, and keep warm at 172-178°C React for 20 minutes until the bronze-colored liquid crystal is filamentous. When the rotation speed drops significantly to 320r / min or below, the polymerization reaction is over, and the stirring ...

Embodiment 3

[0071] Example 3 O 3 -PBI (poly-2,6-benzoxazole-p-phenylenebenzimidazole) and its monofilament fibers

[0072]

[0073] A) poly-2,6-benzoxazole-p-phenylenebenzimidazole (1:1)O 3 -PBI

[0074] Sequentially add P into the glass polymerization reaction column 2 o 5 Mass concentration is 85.3% polyphosphoric acid (PPA) 18.0g and P 2 o 5 3.40g, turn on the spiral stirring, and raise the temperature to 100°C and control the speed of 350r / min to stir for 30min and wait for P 2 o 5 After the reaction was dissolved, pass N 2 Slowly add 3.256g of TATAB and 1.639g of HABA (mol ratio 1:1, mass ratio 0.665:0.334) sequentially under protection for 3 minutes, light brown fluorescence appears when the temperature rises slowly to 180°C under stirring for 40 minutes after addition, keep warm at 177-182°C React for 15 minutes until the bronze-colored liquid crystal is filamentous, and when the rotation speed drops significantly to 320r / min or below, the polymerization reaction is ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com