Method for leaching nickel-cobalt raw material by roasting SO2-containing tail gas by using molybdenum concentrate

A SO2, molybdenum concentrate technology, applied in the direction of improving process efficiency, can solve the problems of secondary pollution, difficult to control the amount of lime, uneconomical and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

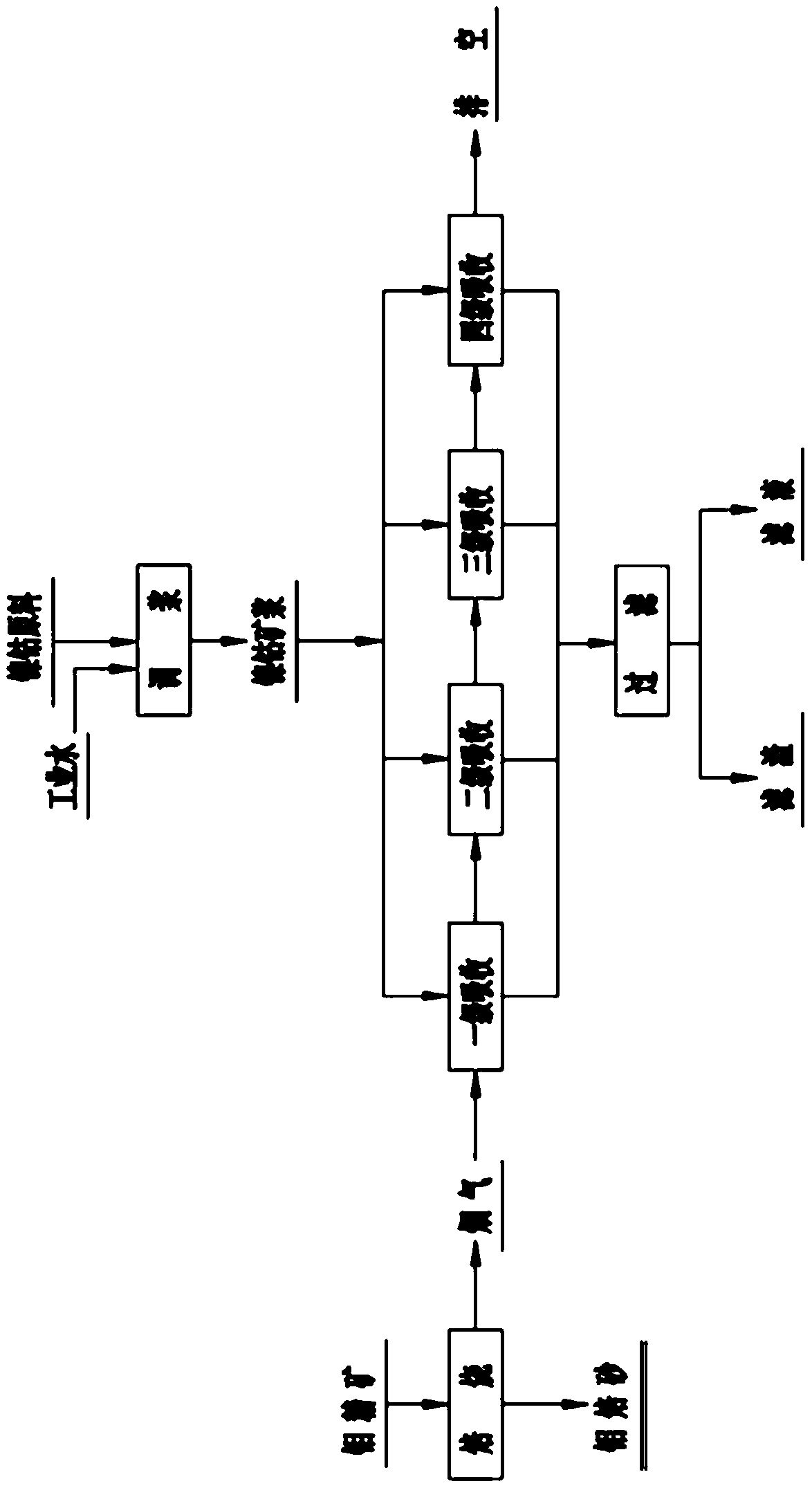

[0030] combine figure 1 , the present invention utilizes molybdenum concentrate to roast SO 2 The method for leaching nickel-cobalt raw material from tail gas mainly comprises the following steps:

[0031] 1. Roasting

[0032] The molybdenum concentrate is pretreated and heated to remove most of the water and oil before being used. After the temperature of the rotary kiln is raised to 400°C, the dried molybdenum concentrate is fed from the feed end of the rotary kiln (that is, the tail of the furnace), and the molybdenum concentrate In the rotary kiln, the ore moves toward the discharge end of the furnace head with the rotation of the furnace body, and a series of chemical reactions occur at the same time. After the reaction time is reached, the qualified molybdenum calcined sand comes out from the discharge end.

[0033] Contains SO 2 After the flue gas (dust) is washed by the washing tower, SO 2 Exhaust gas is introduced into the primary absorption tank.

[0034] This s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com