A kind of Al-Si alloy layered gradient material and its preparation, processing and application

A technology of aluminum-silicon alloy and gradient material, which is applied in the direction of metal material coating process, coating, semiconductor/solid-state device parts, etc., can solve the problem of thermal expansion coefficient matching of electronic packaging materials, lightweight and airtight welding, and mechanical properties. And welding performance is not ideal, it is difficult to meet the problems of thermal expansion matching at the same time, to achieve the effect of improving process stability, low density and strong designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

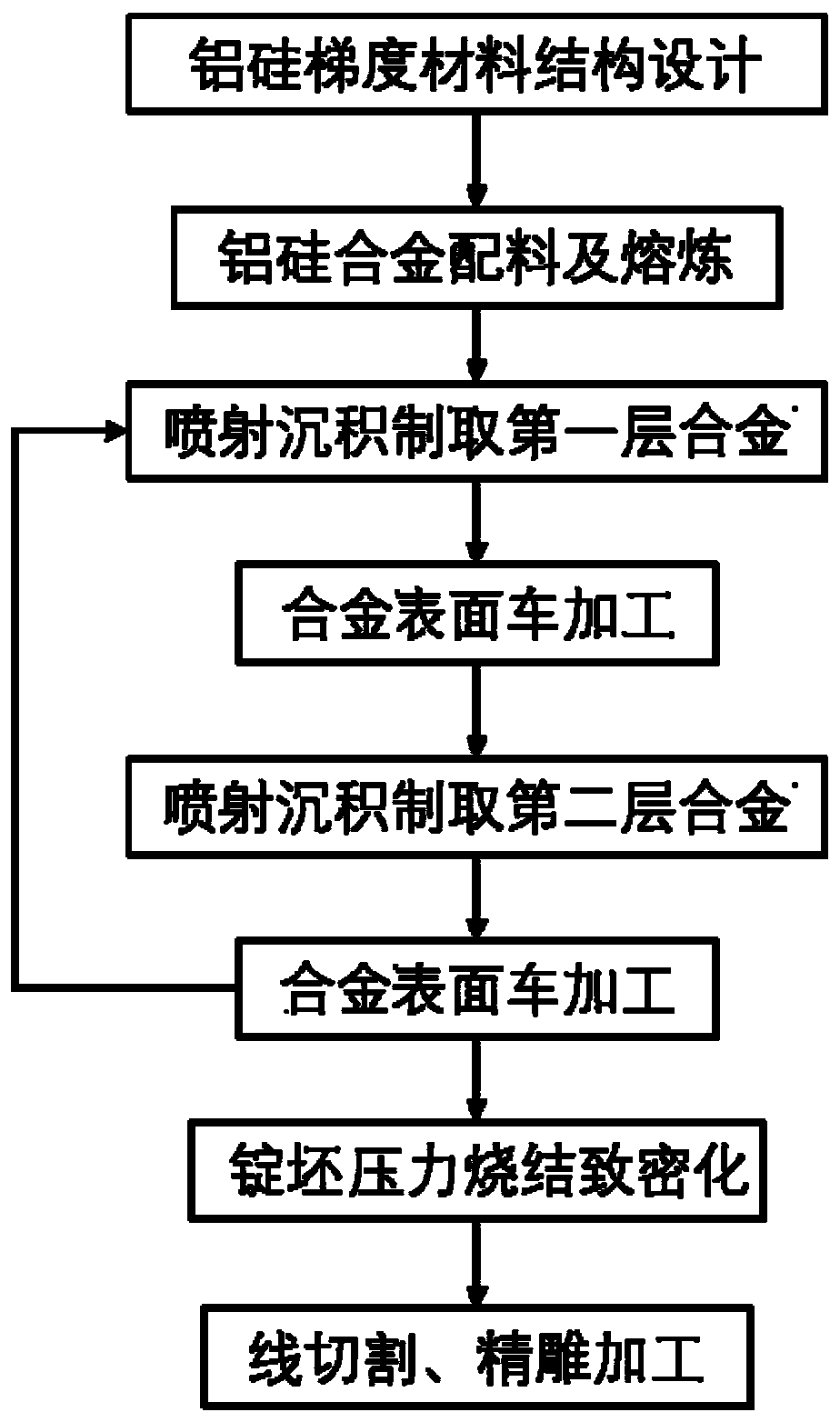

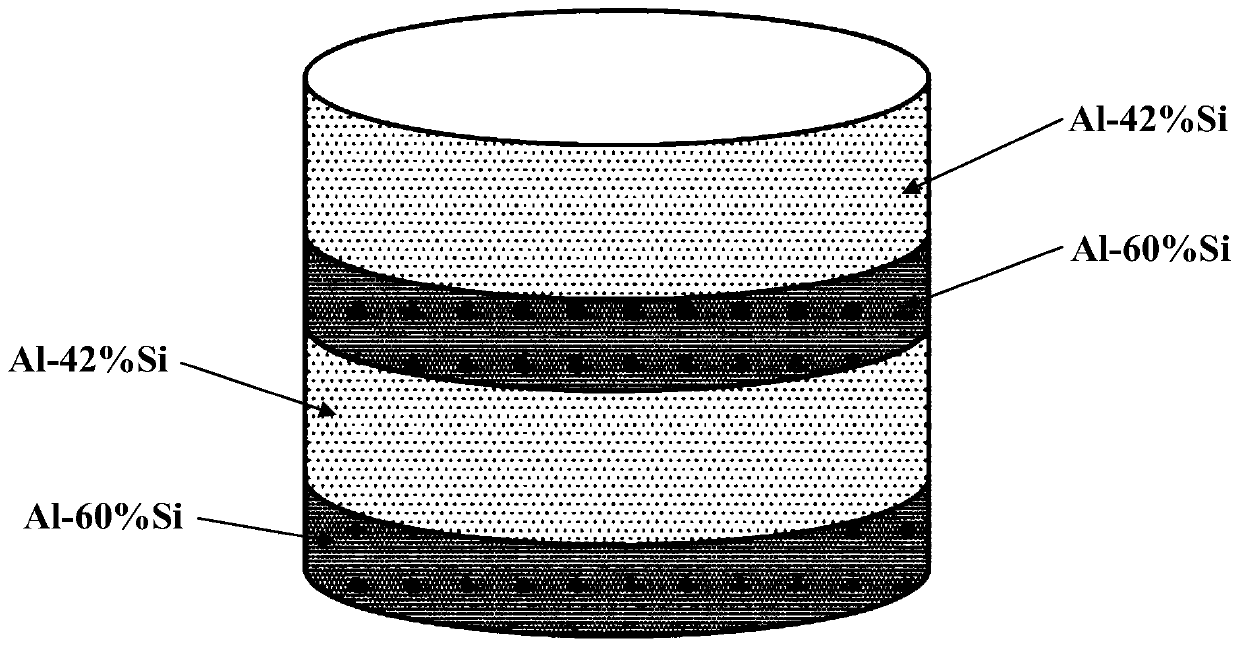

[0041] This embodiment prepares an aluminum-silicon alloy double-layer gradient material (Al-42%Si / Al-60%Si double-layer gradient material), and processes it into an electronic packaging shell, please refer to figure 1 ,Specific steps are as follows:

[0042]S1: First design the number of layers and the composition of each layer of the Al-Si alloy layered gradient material. The material designed in this embodiment is an Al-42%Si / Al-60%Si double-layer gradient material, wherein Al-42%Si The thickness of the alloy layer is 10.0±0.5mm, the thickness of the Al-60% Si alloy layer is 2.0±0.3mm, corresponding to the weight distribution of 42% silicon, the balance is aluminum, and 60% silicon, the balance is aluminum Raw materials with a silicon content of 42% and 60% were prepared respectively, and pure aluminum ingots and monocrystalline silicon blocks with a purity of 99.95% were selected to prepare raw materials.

[0043] S2: Melt the raw materials prepared in step (1) with a sil...

Embodiment 2

[0054] In this embodiment, an aluminum-silicon alloy three-layer gradient material (Al-27%Si / Al-50%Si / Al-70%Si three-layer gradient material) is prepared, and it is processed into an electronic packaging shell. The specific steps are as follows :

[0055] S1: First design the number of layers and the composition of each layer of the Al-Si alloy layered gradient material. The material designed in this embodiment is a three-layer gradient material of Al-27%Si / Al-50%Si / Al-70%Si, wherein , the thickness of Al-27%Si alloy layer is 4.0±0.5mm, the thickness of Al-50%Si alloy layer is 4.0±0.3mm, the thickness of Al-70%Si alloy layer is 2.0±0.3mm, corresponding to silicon 27%, the balance is aluminum, silicon is 50%, the balance is aluminum, and silicon is 70%, the balance is the weight percentage ratio of aluminum, and the raw materials with silicon content of 27%, 50% and 70% are prepared respectively. And choose pure aluminum ingots and monocrystalline silicon blocks with a purity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com