Surface moisture resisting agent for base paper, production method of surface moisture resisting agent and application of surface moisture resisting agent in papermaking

A production method and anti-moisture agent technology, applied in textiles and papermaking, papermaking, paper coating, etc., can solve the problems of unsatisfactory high-strength base paper ring compressive strength, single function, poor surface strength, etc., and achieve excellent film-forming properties And the transfer performance of the whole film, improve the moisture resistance, reduce the effect of expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

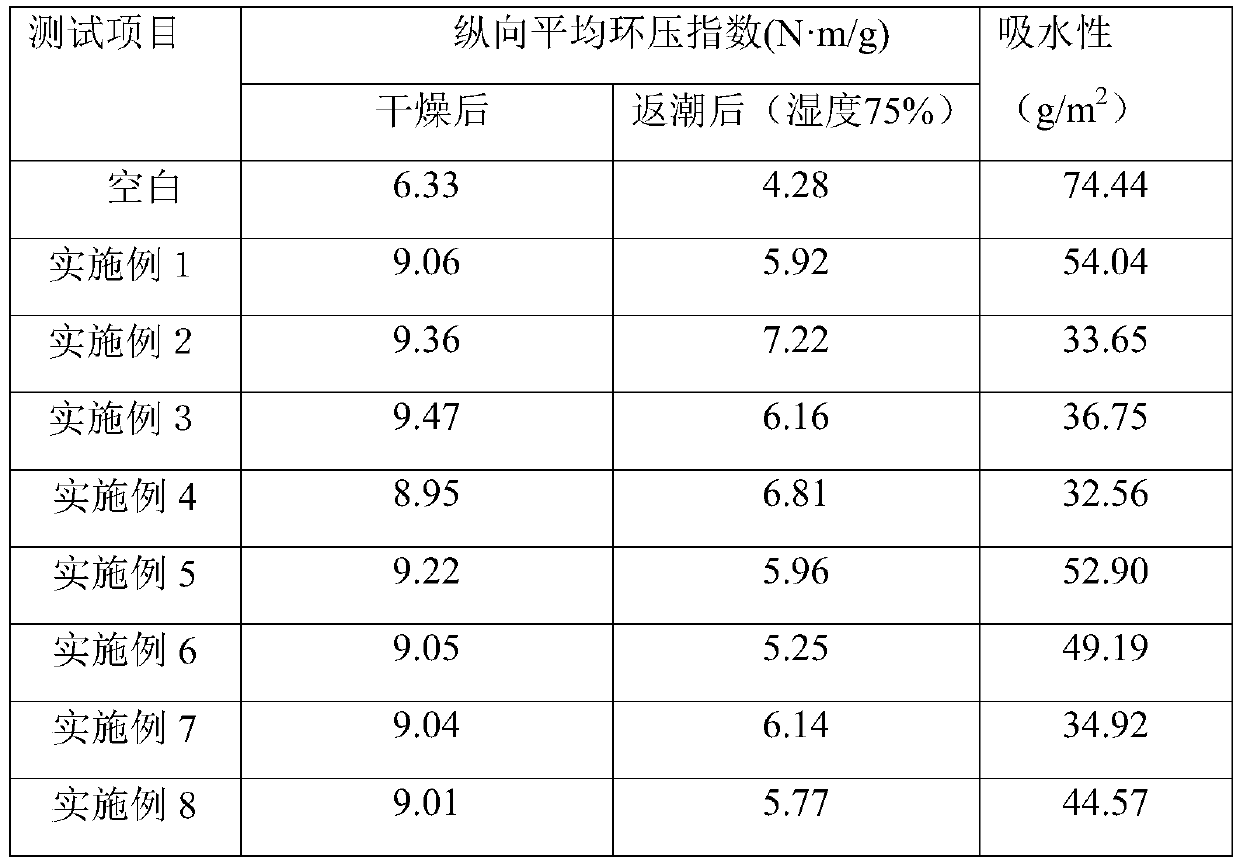

Examples

Embodiment 1

[0030] A kind of preparation method of base paper surface anti-moisture agent of the present embodiment, described method comprises the steps:

[0031] (1) Preparation of cationic polyacrylamide starch polymer: In a 1000L enamel reaction kettle, add 120Kg content of 55% hydroxyacrylamide monomer, 15Kg vinyl tris (isopropoxy) silane, 540Kg content of 16.5% hydrolyzed starch The supernatant was mixed, the temperature was raised to 45°C, 3kg of 30% ammonium persulfate aqueous solution was added dropwise, and then stirred and reacted at 50°C for 5h. After the reaction was finished, it was cooled to room temperature to obtain a cationic polyacrylamide starch polymer with a weight of 675Kg and a solid content of 25%.

[0032] (2) Preparation of anti-moisture agent for base paper: respectively weigh 35Kg of styrene-acrylic surface sizing agent; 675Kg of cationic polyacrylamide starch polymer with a content of 25%. Add it to a high-speed homogeneous disperser in batches, disperse for...

Embodiment 2

[0034] A kind of preparation method of base paper surface anti-moisture agent of the present embodiment, described method comprises the steps:

[0035] (1) Preparation of cationic polyacrylamide starch polymer: In a 1500L enamel reactor, add 120Kg content of 55% hydroxyacrylamide monomer, 20Kg content of 80% acryloyloxyethyltrimethylammonium chloride, 800Kg content of 16.5 % hydrolyzed starch clear solution was mixed, the temperature was raised to 45° C., 3 kg of 30% ammonium persulfate aqueous solution was added dropwise, and then stirred and reacted at 55° C. for 3 hours. After the reaction was finished, it was cooled to room temperature to obtain a cationic polyacrylamide starch polymer with a weight of 930Kg and a solid content of 23%.

[0036] (2) Preparation of anti-moisture agent for base paper: Weigh 105Kg of AKD surface sizing agent; 930Kg of cationic polyacrylamide starch polymer with a content of 23%. Add it to a high-speed homogeneous disperser in batches, dispers...

Embodiment 3

[0038] A kind of preparation method of base paper surface anti-moisture agent of the present embodiment, described method comprises the steps:

[0039] (1) Preparation of cationic polyacrylamide starch polymer: In a 2000L enamel reaction kettle, add 120Kg content of 55% hydroxyacrylamide monomer, 25Kg content of 80% methacryloxyethyltrimethylammonium chloride, 1400Kg The hydrolyzed starch clear solution with a content of 16.5% was mixed, the temperature was raised to 45° C., 3 kg of a 30% ammonium persulfate aqueous solution was added dropwise, and then stirred and reacted at 55° C. for 3 hours. After the reaction, it was cooled to room temperature to obtain a cationic polyacrylamide starch polymer with a weight of 1540Kg, a solid content of 20.5%, and a pH value of 5.

[0040](2) Preparation of anti-moisture agent for base paper: 175Kg of styrene-acrylic surface sizing agent and 1540Kg of cationic polyacrylamide starch polymer with a content of 20.5% were weighed respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com