Separated detection system and method for detecting size of deformed steel wire head

A size detection and separation technology, which is applied in the directions of measuring devices, image analysis, image data processing, etc., can solve the problems of heavy detection procedures, etc., and achieve the effects of small equipment size, improved detection efficiency and accuracy, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

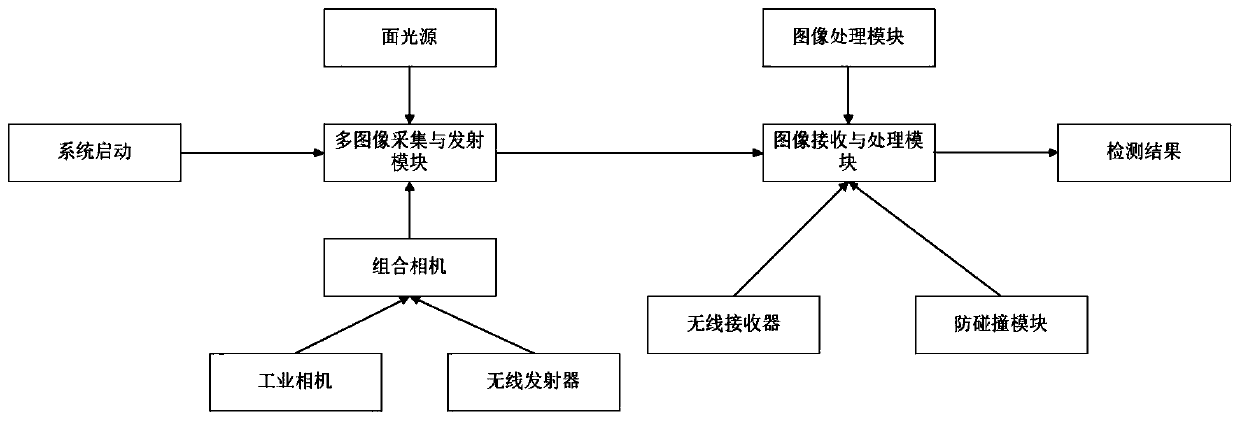

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

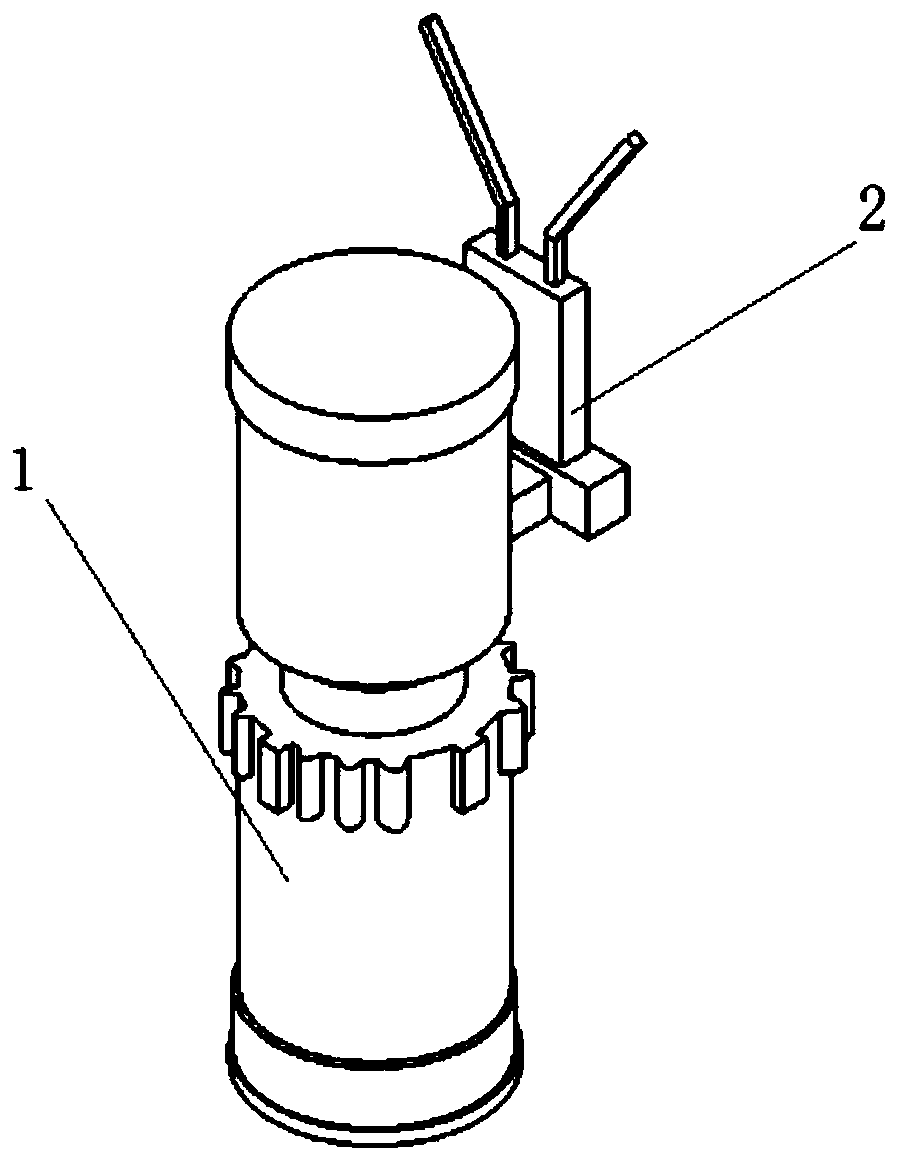

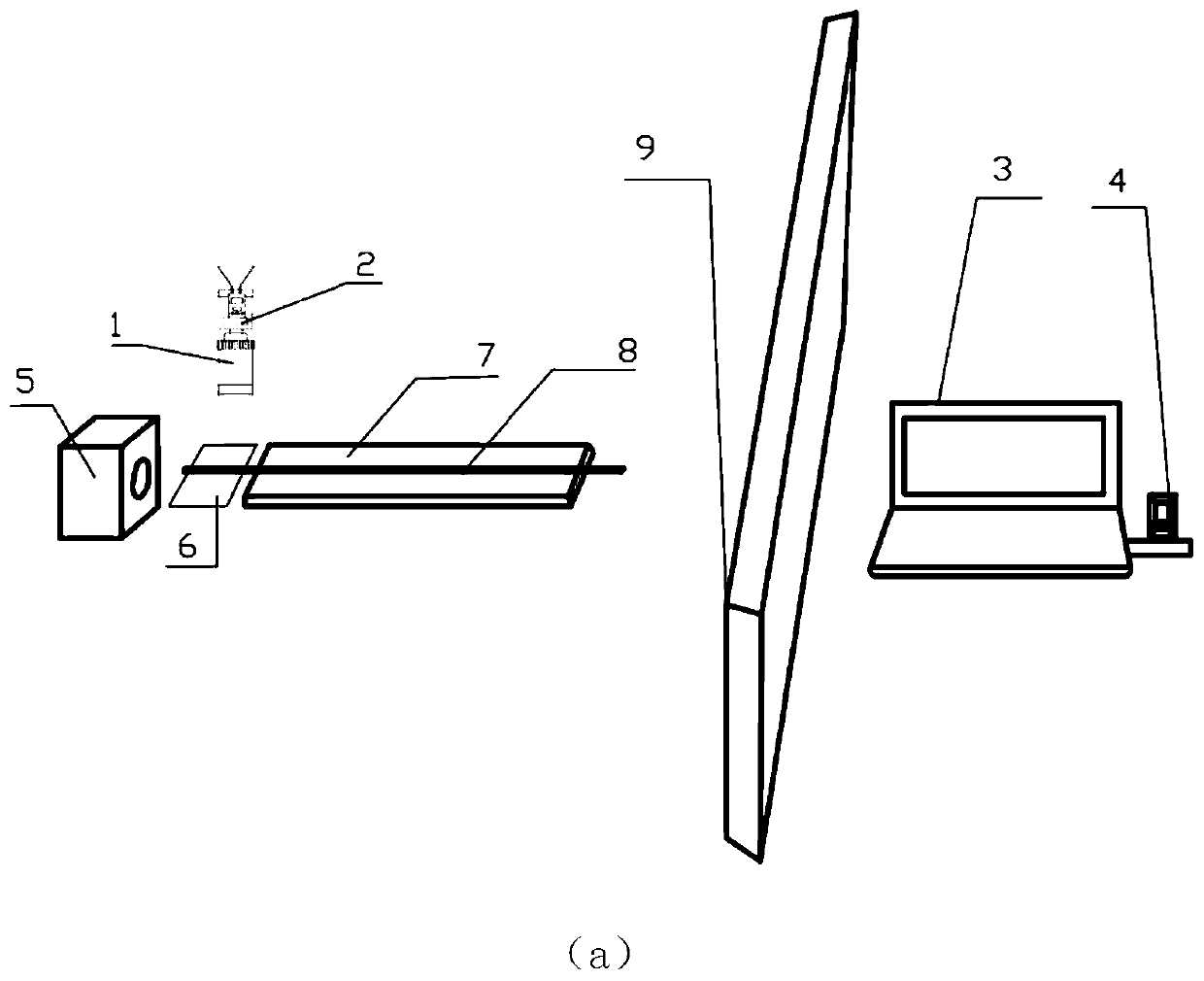

[0074] Such as image 3 (a) shows the schematic diagram of the connection relationship of the single-camera system. In order to illustrate the characteristics of this detection device, an obstacle wall 9 is set up in the system to highlight the characteristics of wireless transmission and reception of this device; The factory for processing steel wire heads, 5 is the thread rolling machine for threaded steel wire head processing, 7 is the rebar conveyor belt used for production, and 8 is the rebar for receiving and testing. Because of the super anti-interference ability of this device, although the processing There is a lot of noise in the factory, but this equipment can still detect the quality of threaded steel wire heads normally.

[0075] When working, the surface light source 6 is vertically irradiated on the threaded steel wire head 8, and at the same time, the industrial camera is placed in the vertical light direction to place the industrial camera 2 to transmit the im...

Embodiment 2

[0077] On the basis of Embodiment 1, if the system contains multiple cameras to detect the image information sent by multiple signal sources, such as image 3 As shown in (b), in the case of "multiple sending and one receiving", assuming that there are three image acquisition devices A, B, and C to collect image information at the same time, any image acquisition device can be used to work at the same time in practical applications.

[0078] Industrial camera C 1 、C 2 、C 3 Work in areas A, B, and C respectively, and transmit the image information collected at A, B, and C to the wireless receiver through the wireless transmitter. At the image receiving end, use the wireless receiver to receive the signal, and then process the signal through the anti-collision module, such as Figure 4 As shown, and then transfer the currently selected image information to the PC, and perform image processing on the PC.

[0079] Such as Figure 5-Figure 7 As shown, the actual size of the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Trail | aaaaa | aaaaa |

| Thread major diameter | aaaaa | aaaaa |

| Trail | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com