Preparation method of titanium alloy substrate composite material with excellent detection performances on hydrogen peroxide

A technology of composite materials and hydrogen peroxide, applied in the field of materials, can solve the problems of detection limit and selectivity that cannot meet the requirements, and achieve the effect of excellent detection performance and excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A method for preparing a composite material of a titanium alloy substrate having excellent detection performance for hydrogen peroxide, the preparation method comprising the following steps:

[0019] (1) Put the nickel-titanium alloy sheet with an atomic ratio of Ni:Ti=50.8:49.2 into 1-5 M / L hydrochloric acid solution, and ultrasonically clean it for 10-30 minutes;

[0020] (2) Put the potassium hydroxide solution with a concentration of 2 M-9M in a high-pressure reactor, put the cleaned nickel-titanium alloy described in step (1), and put it in an environment of 110-130°C for hydrothermal reaction 1- 6 hours;

[0021] (3) After the reaction is over, wait for the autoclave to cool down to room temperature naturally, take out the nickel-titanium alloy sheet, and clean it thoroughly;

[0022] (4) Dry the cleaned nickel-titanium alloy sheet in a vacuum oven at 30-80°C for 2-6 hours.

[0023] Since the sensitivity, detection limit, and selectivity of conventional material...

Embodiment 1

[0025] A method for preparing a composite material of a titanium alloy substrate having excellent detection performance for hydrogen peroxide, the preparation method comprising the following steps:

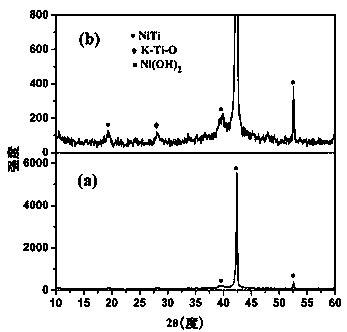

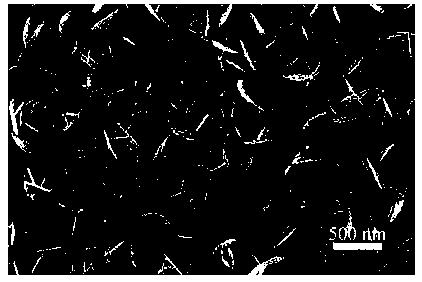

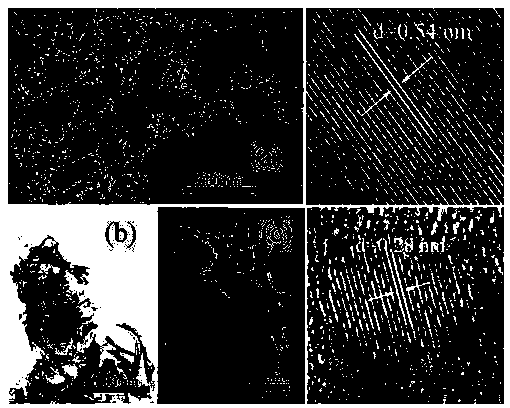

[0026] (1) Put a nickel-titanium alloy sheet (atomic ratio: Ni:Ti=50.8:49.2) (size: 4cm×2cm×0.1cm) into 3M / L hydrochloric acid solution, and ultrasonically clean it for 10 minutes;

[0027] (2) Put the potassium hydroxide solution with a concentration of 6 M in the autoclave, put the cleaned nickel-titanium alloy described in step (1), and put it in a 110°C environment for hydrothermal reaction for 2 hours;

[0028] (4) After the reaction is over, wait for the autoclave to cool down to room temperature naturally, take out the nickel-titanium alloy sheet, and rinse it with deionized water and alcohol alternately for 5 times;

[0029] (5) Dry the cleaned nickel-titanium alloy sheet in a vacuum oven at 60°C for 2 hours.

Embodiment 2

[0031] A method for preparing a composite material of a titanium alloy substrate having excellent detection performance for hydrogen peroxide, the preparation method comprising the following steps:

[0032] (1) Put a nickel-titanium alloy sheet with an atomic ratio of Ni:Ti=50.8:49.2 in a 1 M / L hydrochloric acid solution, and ultrasonically clean it for 10 minutes;

[0033] (2) Put a potassium hydroxide solution with a concentration of 2 M in an autoclave, put the cleaned nickel-titanium alloy described in step (1), and put it in a 130°C environment for hydrothermal reaction for 1 hour;

[0034] (3) After the reaction is over, wait for the autoclave to cool down to room temperature naturally, take out the nickel-titanium alloy sheet, and clean it thoroughly;

[0035] (4) Dry the cleaned nickel-titanium alloy sheet in a vacuum oven at 30°C for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com