Photocatalytic aggregate taking regenerated asphalt aggregate as matrix and preparation method thereof

A technology of regenerated asphalt and photocatalysis, which is applied in the direction of chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., to achieve the effect of improving cost-efficiency ratio, good economic and environmental benefits, and overcoming catalyst spalling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

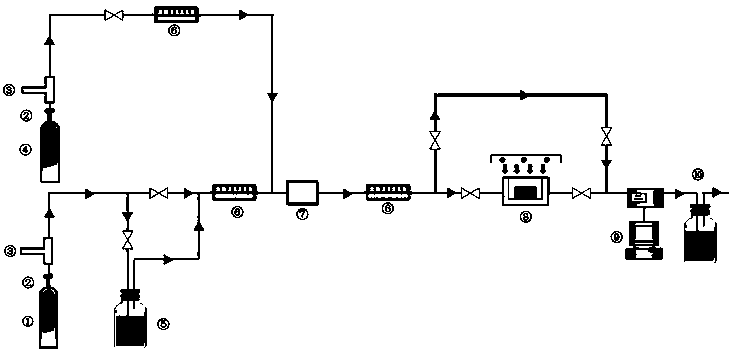

Image

Examples

Embodiment 1

[0027] The photocatalytic aggregate based on the recycled asphalt aggregate in the example of the present invention is mainly made of the following raw materials in mass percentage: the recycled asphalt aggregate is: 92%, nano-sheet g-C 3 N 4 is 8%, and the total weight of the two satisfies 100%. The recycled asphalt aggregate with a specification of 0.05-3 mm is taken, and its main components are as follows: 5% asphalt, SiO 2 45%, CaCO 3 38%, Fe 2 o 3 3%, Al 2 o 3 9%.

[0028] The preparation method of the photocatalytic aggregate taking the regenerated asphalt aggregate of the example of the present invention as the matrix, the concrete steps are:

[0029] (1) Take nanosheet g-C 3 N 4 Ultrasonic dispersion in absolute ethanol for 3 hours yielded nanosheet g-C 3 N 4 Dispersion, in which absolute ethanol and nanoflake g-C 3 N 4 The mass ratio is: 8:1;

[0030] (2) Take the recycled asphalt aggregate and ultrasonically treat it in 0.1M sodium hydroxide solutio...

Embodiment 2

[0034] The photocatalytic aggregate based on the recycled asphalt aggregate of the example of the present invention is mainly made of the following raw materials in mass percentage: the recycled asphalt aggregate is: 96%, block g-C 3 N 4 is 4%, and the total weight of the two satisfies 100%. The recycled asphalt aggregate with a specification of 3-5 mm is taken, and its main components are as follows: 4% asphalt, SiO 2 46%, CaCO 3 38%, Fe 2 o 3 3%, Al 2 o 3 9%.

[0035] The preparation method of the photocatalytic aggregate taking the regenerated asphalt aggregate of the example of the present invention as the matrix, the concrete steps are:

[0036] (1) Take block g-C 3 N 4 Ultrasonic dispersion in absolute ethanol for 2 hours to obtain block g-C 3 N 4 Dispersion, in which absolute ethanol and block g-C 3 N 4 The mass ratio is: 16:1;

[0037] (2) Take regenerated asphalt aggregates and ultrasonically treat them in 0.1M sodium hydroxide solution for 45 minute...

Embodiment 3

[0041] The photocatalytic aggregate based on the recycled asphalt aggregate of the example of the present invention is mainly made of the following raw materials in mass percentage: the recycled asphalt aggregate is: 95%, nano-sheet g-C 3 N 4 5%, and the total weight of the two satisfies 100%. The recycled asphalt aggregate with a specification of 5-10 mm is taken, and its main components are as follows: 4% asphalt, SiO 2 46%, CaCO 3 38%, Fe 2 o 3 3%, Al 2 o 3 9%.

[0042] The preparation method of the photocatalytic aggregate taking the regenerated asphalt aggregate of the example of the present invention as the matrix, the concrete steps are:

[0043] (1) Take nanosheet g-C 3 N 4 Ultrasonic dispersion in absolute ethanol for 1 hour yielded nanosheet g-C 3 N 4 Dispersion, in which absolute ethanol and nanoflake g-C 3 N 4 The mass ratio is: 10:1;

[0044] (2) Ultrasonically treat recycled asphalt aggregates in 0.1M sodium hydroxide solution for 30 minutes, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com