Method for purifying recombinant protein

A recombinant protein and purification method technology, which is applied in the preparation methods of peptides, chemical instruments and methods, single-component protein rayon, etc., can solve problems such as gelation, and achieve the effect of fewer steps and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0212] (1) Preparation of Polypeptide Solution (Spinning Dope) As described above, the second soluble fraction in which the recombinant protein is dissolved in step (D) does not require further purification steps and can be used as a so-called spinning solution in step (D). (E) Spinning. The viscosity suitable for spinning is usually 10 to 10000 cP (centipoise), and the viscosity can be measured using, for example, a trade name "EMS viscometer" manufactured by Kyoto Denshi Kogyo Co., Ltd. In the case where the viscosity of the second soluble fraction obtained in the step (D) is not in the range of 10 to 10000 cP (centipoise), the viscosity of the second soluble fraction may be adjusted to a viscosity capable of spinning. The viscosity can be adjusted by using the aprotic polar solvents exemplified as preferable solvents in the description of the step (A). The aprotic polar solvent may contain the preferred inorganic salts exemplified in the description of step (A).

[0213] ...

Embodiment 1

[0252] [Example 1 Influence of Inorganic Salt and Temperature in Dissolution Step of Host Cell-derived Protein]

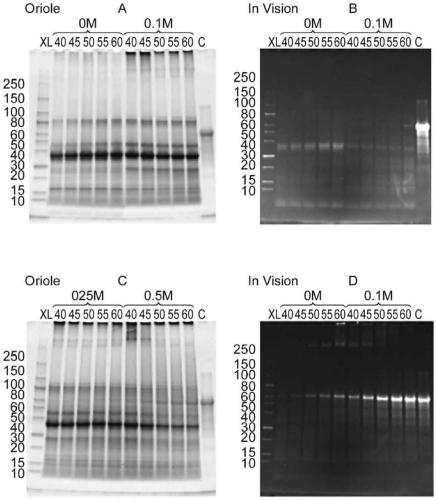

[0253] In the step of dissolving the host cell-derived protein, the addition of the inorganic salt to the first aprotic polar solvent, the concentration of the addition, and the influence of the temperature were examined. Add 1 mL of DMSO containing 0M, 0.1M, 0.25M and 0.5M lithium chloride to 50 mg of dry cells expressing Escherichia coli PRT468, and conduct 30 minutes to process. After cooling to room temperature, centrifugation was performed at 11,000×g for 5 minutes. The supernatant (first soluble fraction) obtained by centrifugation was analyzed by SDS-PAGE. show the result in figure 1 . The numbers from 40 to 60 indicate the temperature, and the symbols from 0 to 0.5M indicate the concentration of lithium chloride contained in DMSO. Lane XL is the result of electrophoresis of molecular weight marker proteins, and lane C is the result of electrophoresis o...

Embodiment 2

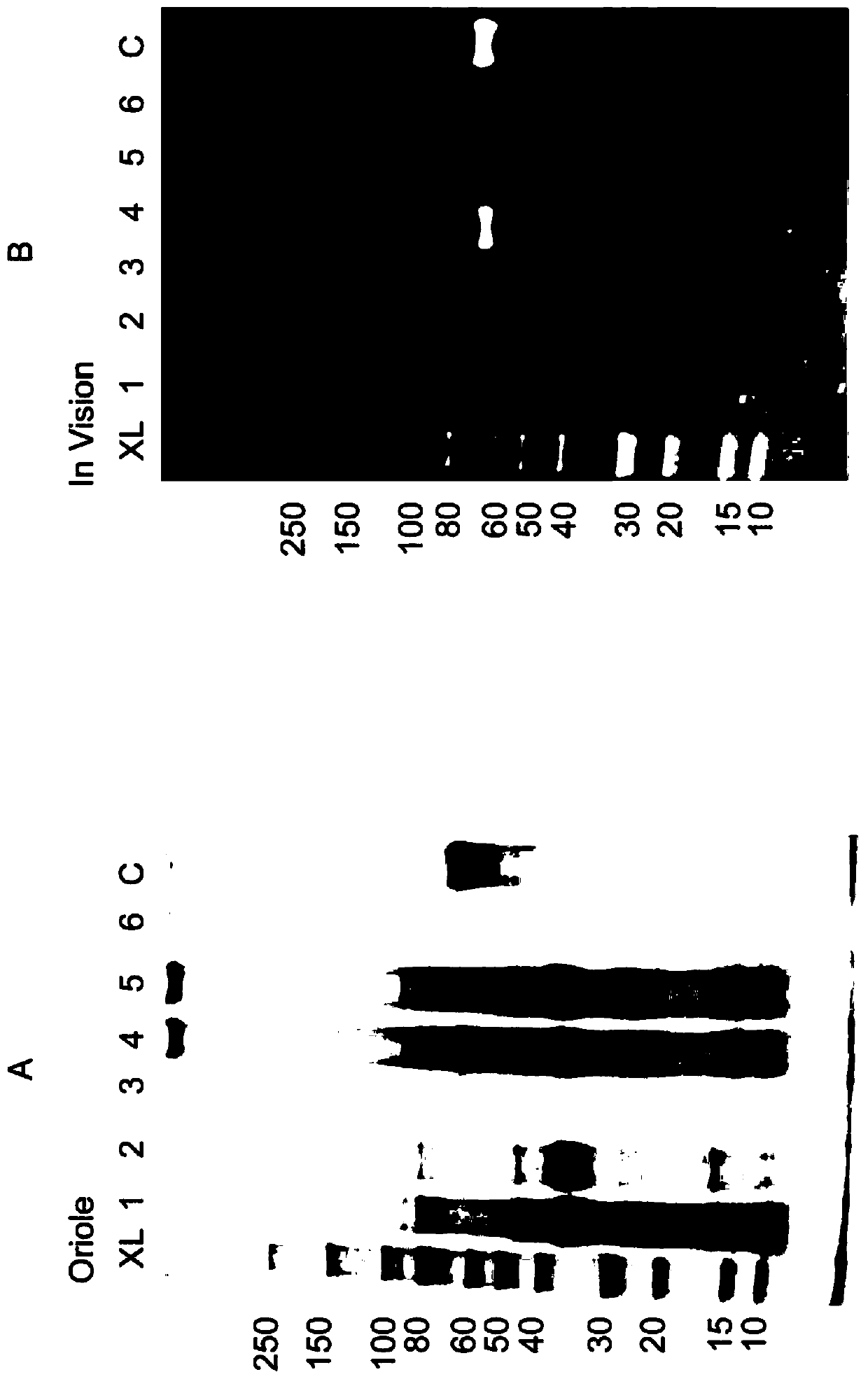

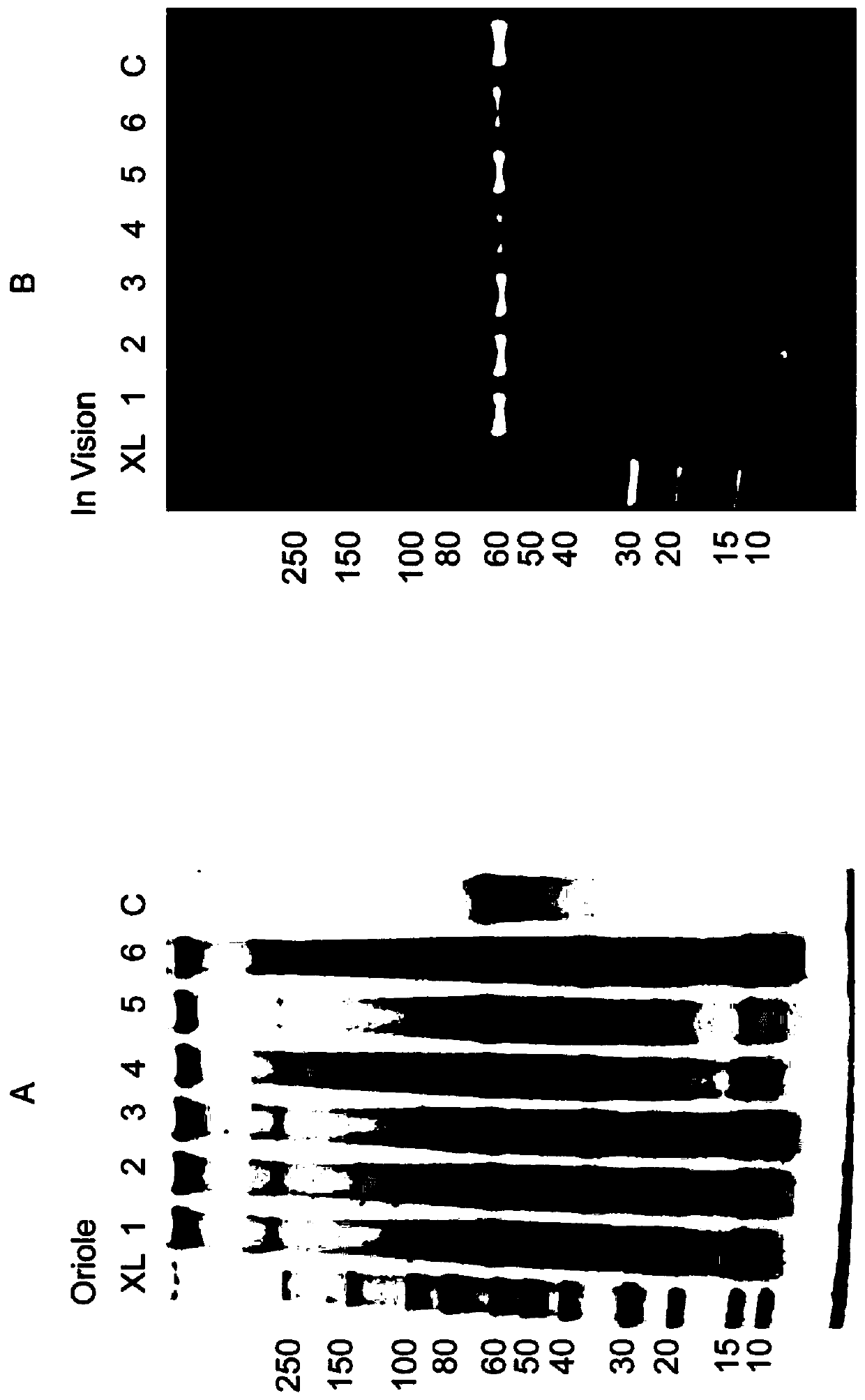

[0256] [Example 2 One of the effects of adding cyclohexanone in the solubilization step of host cell-derived protein]

[0257] In Example 1, when DMSO containing a high concentration of lithium chloride was used as the first aprotic polar solvent, not only the dissolution of the host cell-derived protein but also the dissolution of the target protein PRT468 was confirmed. Therefore, the effect of preventing the dissolution of PRT468 by adding cyclohexanone to DMSO containing a high concentration of lithium chloride was investigated.

[0258] Prepare solvents with three mixing ratios of DMSO:cyclohexanone=100:0, 50:50, and 25:75, add lithium chloride to these solvents so as to reach 0.1M or 0.5M, and prepare a total of six kinds of first Aprotic polar solvents (see Table 5).

[0259] [table 5]

[0260] Lane No.

Lithium chloride (M)

DMSO(%)

1

0.1

100

0

2

0.1

50

50

3

0.1

25

75

4

0.5

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com