Structure for use in piezoelectric element, braided piezoelectric element, fabric-like piezoelectric element using braided piezoelectric element, and device using these

A technology of piezoelectric elements and structures, applied in the measurement of the force of piezoelectric devices, the manufacture/assembly of piezoelectric/electrostrictive devices, electrical components, etc., can solve problems such as lack of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0585] In the present example, regarding the piezoelectric elements used in the first to third inventions, the effect of the orientation angle θ of the piezoelectric polymer and the value of T1 / T2 on the electric signal for the expansion and contraction deformation was investigated. influences.

[0586] (Example A)

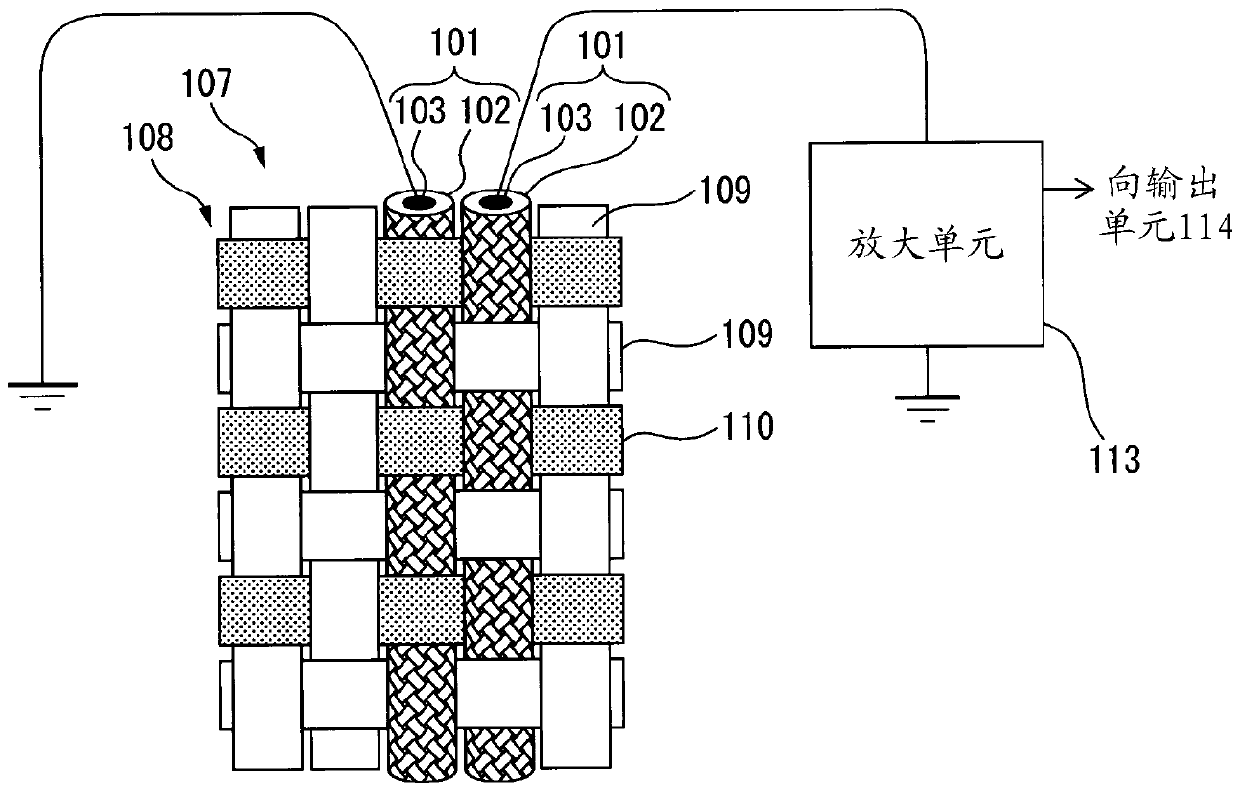

[0587] As a sample of Example A, such as Figure 10As shown, the conductive fiber CF1 is used as the core wire, and the above-mentioned piezoelectric fiber PF1 is placed on the 4 carriers woven along the Z-twist direction among the 8 carriers of the 8-ply round rope rope making machine. The above-mentioned insulating fiber IF1 is woven on four carriers woven in the S-twist direction to produce a cord in which the piezoelectric fiber PF1 is helically wound in the Z-twist direction around the core wire. Shaped piezoelectric element 1-A.

[0588] (Example B)

[0589] Using the rope-shaped piezoelectric element 1-A as the core wire, the above-mentioned four carrie...

Embodiment 2)

[0618] In this example, in the second invention and the third invention, regarding the piezoelectric element that can be used together with the piezoelectric element of Example 1, in particular, the orientation angle θ and T1 / T2 of the piezoelectric polymer were investigated. The effect of the value of on the electrical signal for warping deformation.

[0619] (Example AA)

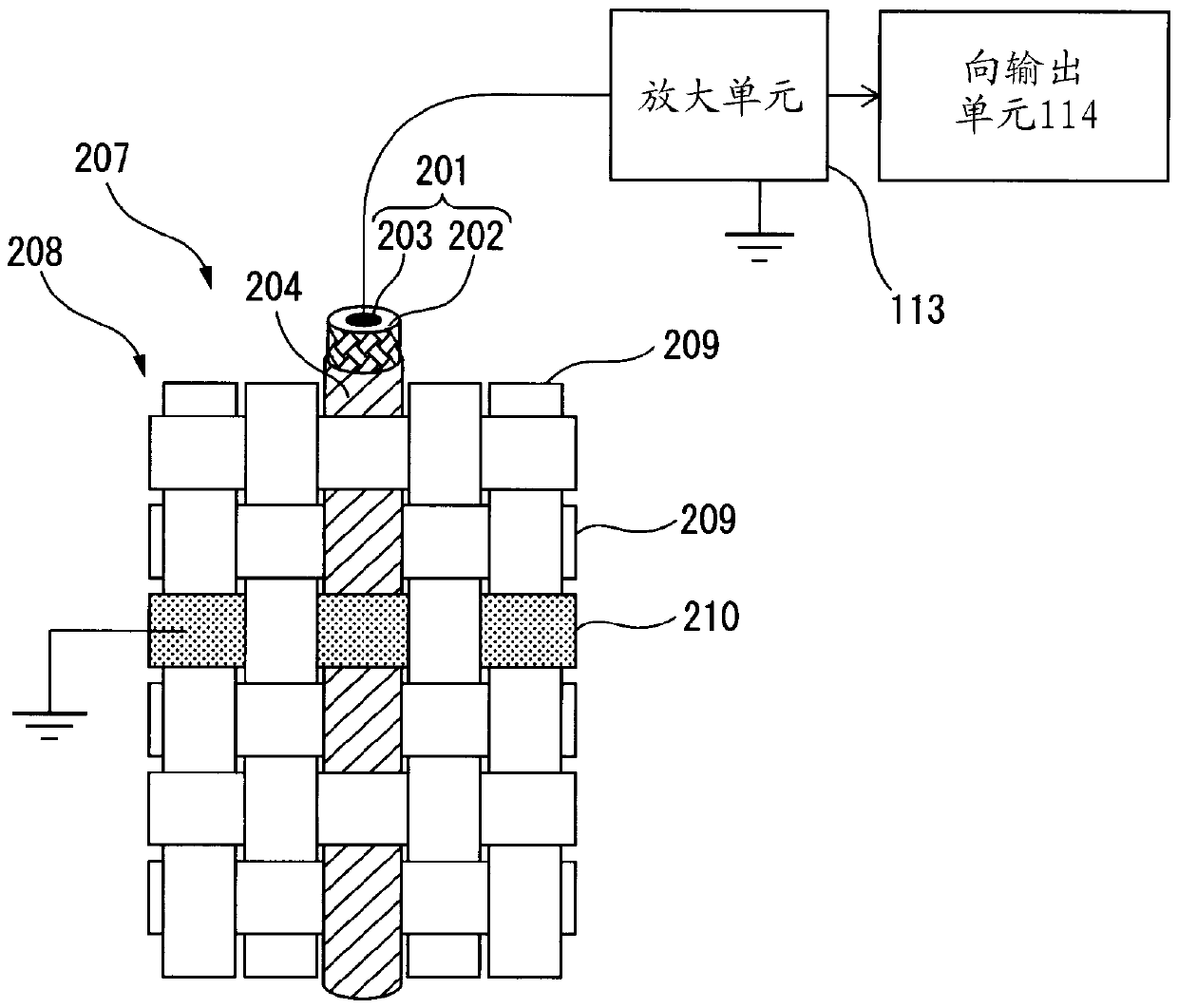

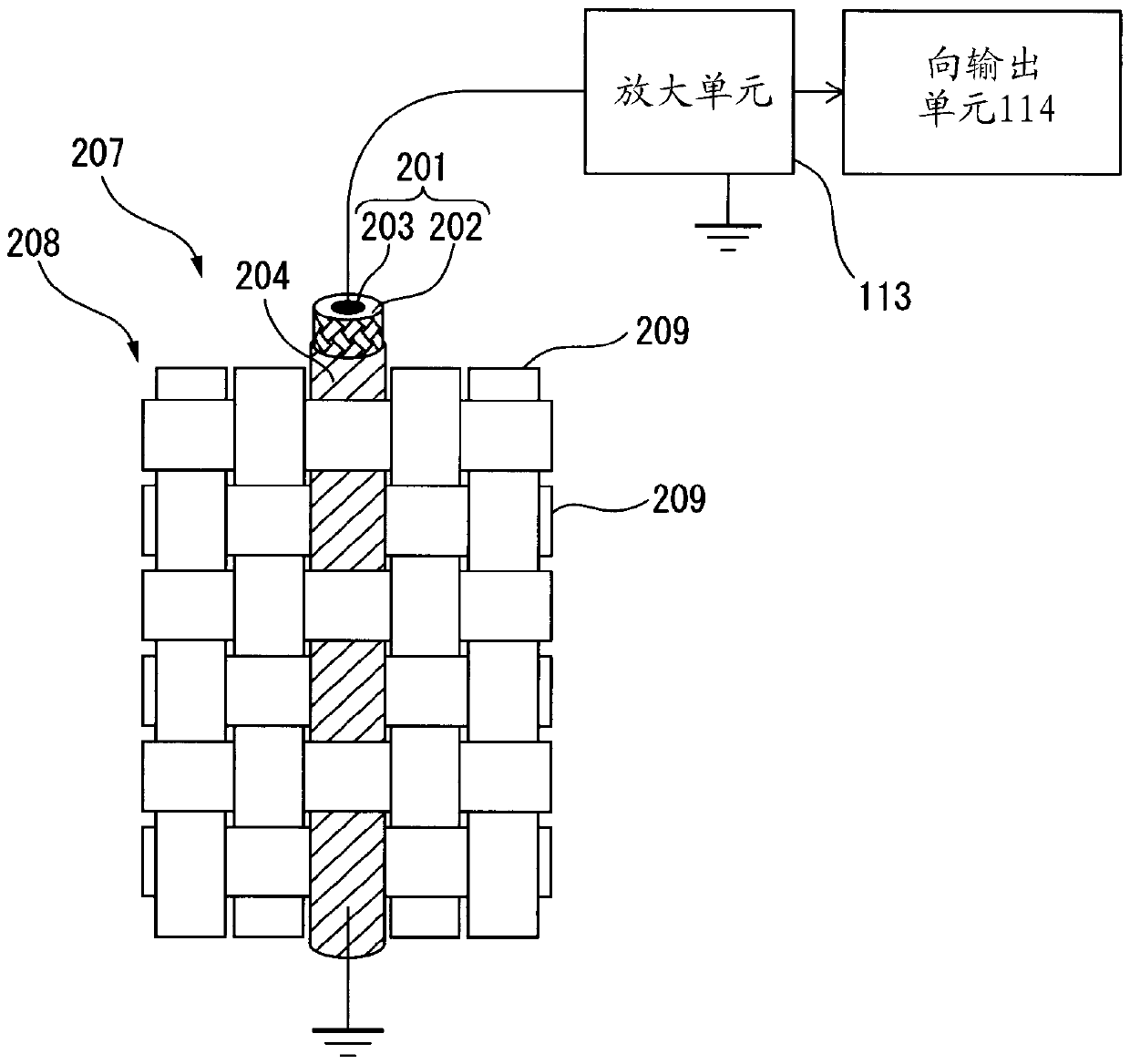

[0620] As the sample of Example 1, such as Figure 10 As shown, using the conductive fiber CF1 as the core wire, all of the 4 carriers woven in the Z twist direction and the 4 carriers woven in the S twist direction among the 8 carriers of the 8-ply round rope rope making machine The above-mentioned piezoelectric fiber PF1 is set and braided, thereby producing a rope-shaped piezoelectric fiber in which the piezoelectric fiber PF1 is wound helically in both the Z-twist direction and the S-twist direction around the core wire. Element 1-AA.

[0621] (Example AB)

[0622] The rope-shaped piezoelectric ele...

Embodiment 3)

[0651] The fabric for piezoelectric elements of the second invention is produced by the following method.

[0652] (Manufacture of polylactic acid)

[0653] The polylactic acid used in the examples was produced by the following method.

[0654] Add 0.005 parts by mass of tin octoate to 100 parts by mass of L-lactide (manufactured by Musashino Chemical Research Institute, optical purity 100%), and react at 180°C with a reactor equipped with stirring blades under a nitrogen atmosphere After 2 hours, 1.2 times the equivalent of phosphoric acid was added to tin octoate, and then the remaining lactide was removed under reduced pressure at 13.3 Pa, and poly-L-lactic acid (PLLA1) was obtained by chipping. The obtained PLLA1 had a mass average molecular weight of 152,000, a glass transition temperature (Tg) of 55°C, and a melting point of 175°C.

[0655] (piezoelectric fiber)

[0656] PLLA1 melted at 240° C. was poured out from the 24-well lid at 22 g / min and retrieved at 1300 m / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com