Chemical oxidation efficient synthesis method of theasinensins

A polyester catechin, chemical oxidation technology, applied in tea, tea extraction, food science, etc., can solve the problem that the yield does not exceed 30%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

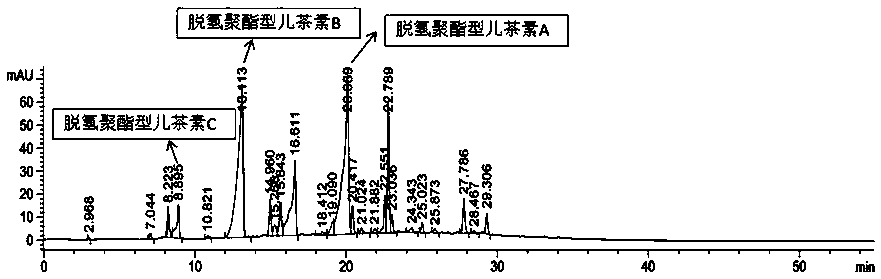

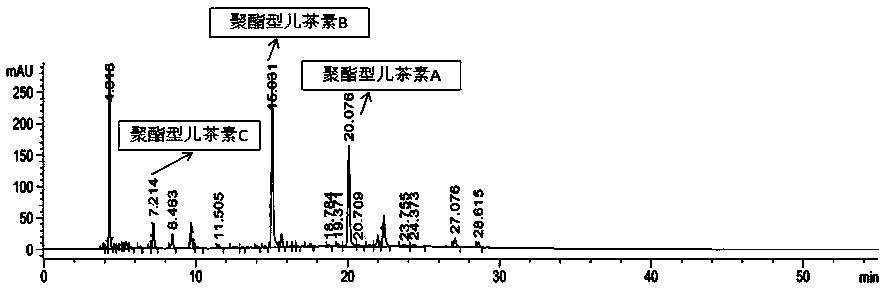

[0020] Weigh an appropriate amount of tea polyphenol (catechin) extract, add a methanol solution with a concentration of 35%, and mix well to obtain a tea polyphenol (catechin) raw material solution; add copper chloride chemical catalyst, the addition amount is 40% , the temperature control reaction temperature is 25°C, the time is 50h, and the conversion of catechin to dehydropolyester-type catechin is promoted; vitamin C is added to continue the reaction, the addition amount is 80%, and the temperature is 80°C, and the time is 14min. Under certain conditions, promote the transformation of dehydropolyester-type catechins into polyester-type catechins; use ethyl acetate as the extraction agent, extract twice in equal volume; vacuum rotary evaporation, freeze-drying (or spray-drying) to obtain polyester Type catechin, the yield was 56.5%.

Embodiment 2

[0022] Weigh an appropriate amount of tea polyphenol (catechin) extract, add a 30% ethanol solution, and mix well to obtain a tea polyphenol (catechin) raw material solution; add copper chloride chemical catalyst, the addition amount is 50% , the temperature control reaction temperature is 25°C, and the time is 72h, which promotes the conversion of catechin to dehydropolyester-type catechin; adding vitamin C to continue the reaction, the addition amount is 85%, and the temperature is 85°C, and the time is 18min. Under certain conditions, promote the transformation of dehydropolyester-type catechins into polyester-type catechins; use ethyl acetate as the extraction agent, extract twice in equal volume; vacuum rotary evaporation, freeze-drying (or spray-drying) to obtain polyester Type catechin, the yield was 58.7%.

Embodiment 3

[0024] Weigh an appropriate amount of tea polyphenol (catechin) extract, add a concentration of 25% isopropanol solution, and mix well to obtain a tea polyphenol (catechin) raw material solution; add copper chloride chemical catalyst, the addition amount is 40%, the temperature control reaction temperature is 22°C, and the time is 28h to promote the conversion of catechins to dehydropolyester-type catechins; add vitamin C to continue the reaction, the addition amount is 85%, and the temperature is 85°C, the time is Under the condition of 12min, promote the conversion of dehydropolyester-type catechin to polyester-type catechin; use ethyl acetate as the extractant, extract 3 times in equal volume; vacuum rotary evaporation, freeze-drying (or spray-drying) to obtain The yield of polyester catechin is 52.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com