Nitrogen-removal phosphorus-removal composite filler and preparation method thereof

A composite filler, denitrification and phosphorus removal technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problem of high porosity of synthetic zeolite, inability to meet sewage treatment standards, and low cost And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

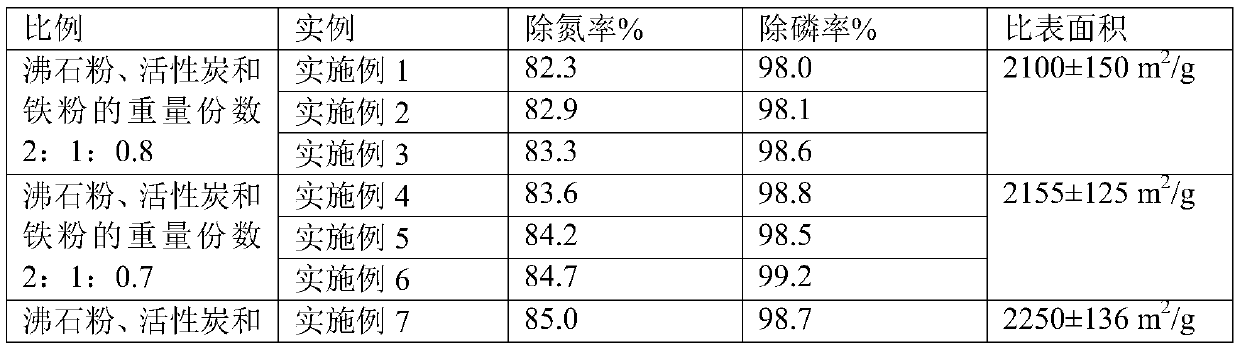

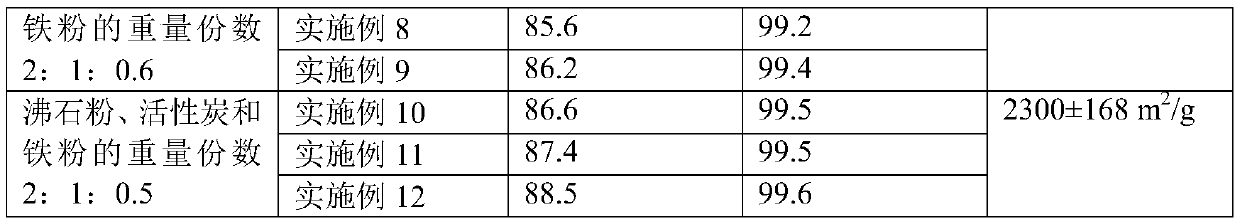

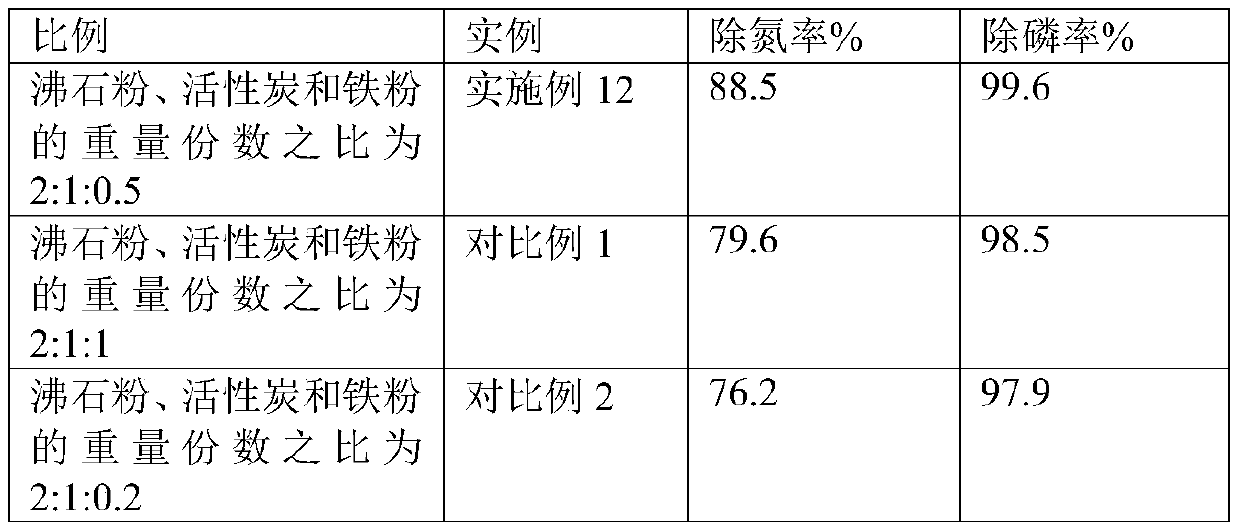

Examples

Embodiment 1

[0118] Example 1 A kind of nitrogen and phosphorus removal composite filler with excellent water treatment effect

[0119] The composite filler is composed of the following raw materials in parts by weight: 10 parts of zeolite powder, 5 parts of activated carbon and 4 parts of iron powder;

[0120] Preparation method: comprising the following steps:

[0121] (1) zeolite particles are ground and sieved to obtain zeolite powder, which is set aside;

[0122] (2) active carbon is sieved, obtains active carbon powder, standby;

[0123] (3) getting particle size is the iron powder of 40-150um, for subsequent use;

[0124] (4) according to formula consumption, zeolite powder, iron powder and activated carbon powder are mixed evenly to obtain batching;

[0125] (5) Spray water evenly on the non-woven fabric to make the surface moist, and then coat the ingredients obtained in the step (4) on the non-woven fabric side surface;

[0126] (6) Lay the non-woven fabric wrapped with ingre...

Embodiment 2

[0129] Example 2 A kind of nitrogen and phosphorus removal composite filler with excellent water treatment effect

[0130] The composite filler is composed of the following raw materials in parts by weight: 45 parts of zeolite powder, 22.5 parts of activated carbon and 18 parts of iron powder;

[0131] Preparation method: comprising the following steps:

[0132] (1) zeolite particles are ground and sieved to obtain zeolite powder, which is set aside;

[0133] (2) active carbon is sieved, obtains active carbon powder, standby;

[0134] (3) getting particle size is the iron powder of 40-150um, for subsequent use;

[0135] (4) according to formula consumption, zeolite powder, iron powder and activated carbon powder are mixed evenly to obtain batching;

[0136] (5) Spray water evenly on the non-woven fabric to make the surface moist, and then coat the ingredients obtained in the step (4) on the non-woven fabric side surface;

[0137] (6) Lay the non-woven fabric wrapped with i...

Embodiment 3

[0140] Example 3 A kind of nitrogen and phosphorus removal composite filler with excellent water treatment effect

[0141] The composite filler is composed of the following raw materials in parts by weight: 100 parts of zeolite powder, 50 parts of activated carbon and 40 parts of iron powder

[0142] Preparation method: comprising the following steps:

[0143] (1) zeolite particles are ground and sieved to obtain zeolite powder, which is set aside;

[0144] (2) active carbon is sieved, obtains active carbon powder, standby;

[0145] (3) getting particle size is the iron powder of 40-150um, for subsequent use;

[0146] (4) according to formula consumption, zeolite powder, iron powder and activated carbon powder are mixed evenly to obtain batching;

[0147] (5) Spray water evenly on the non-woven fabric to make the surface moist, and then coat the ingredients obtained in the step (4) on the non-woven fabric side surface;

[0148] (6) Lay the non-woven fabric wrapped with ing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com