Method for preparing high-purity lithium hydroxide

A lithium hydroxide and purity technology, applied in the field of high-purity lithium, can solve the problems of high energy consumption, high cost, and difficulty in removing impurities, and achieve high material utilization, less impurity components, and environmentally friendly processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

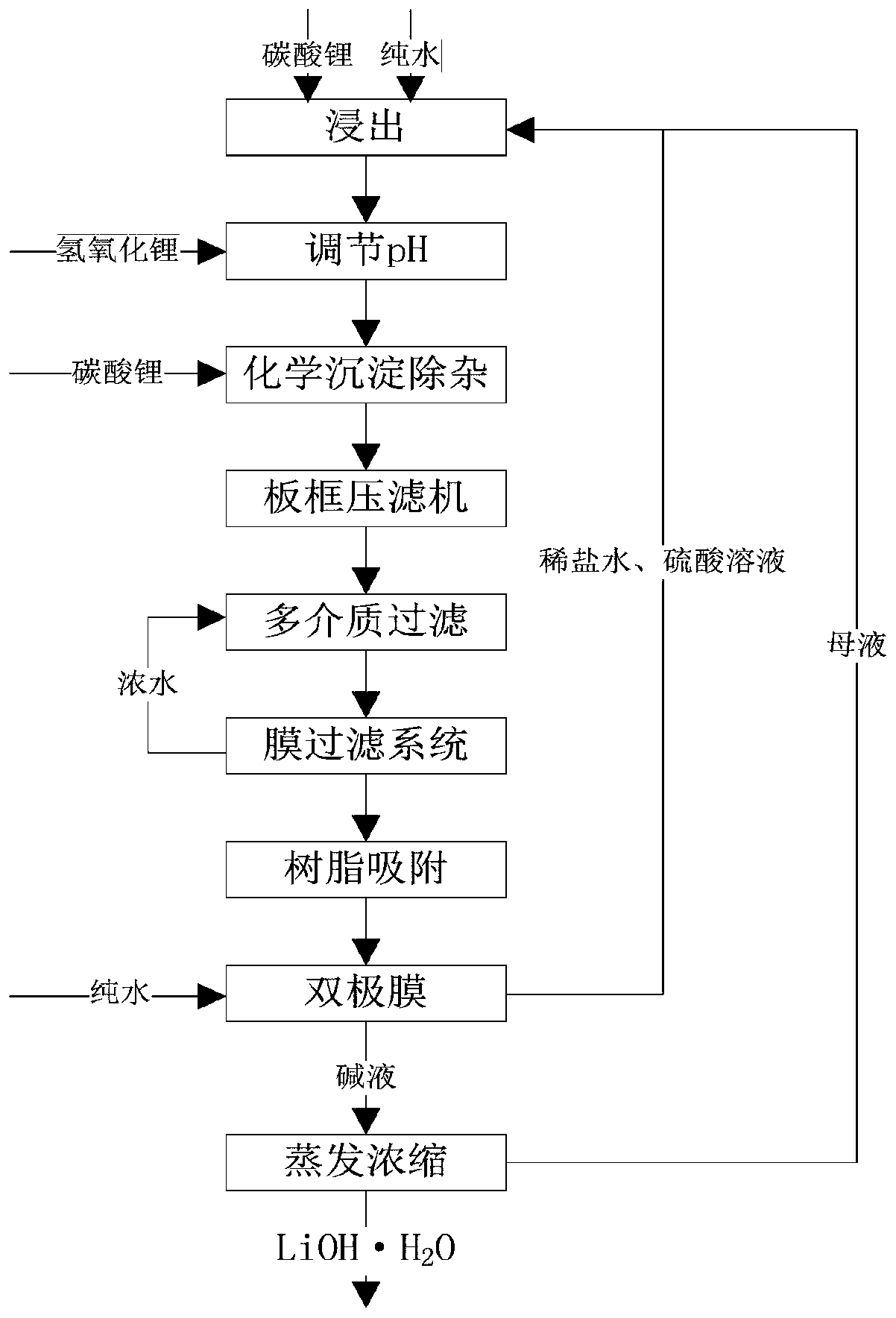

Image

Examples

Embodiment 1

[0053] Preparation of high-purity lithium hydroxide from industrial grade lithium carbonate

[0054] Industrial grade lithium carbonate composition: Li 2 CO 3 98.1%, Na 2 O 0.26%, CaO 0.21%, SO 4 2— 0.62%, Fe 2 o 3 0.32%, MgO 0.26%, salt and inclusions 0.031%.

[0055] (1) Dilute industrial grade lithium carbonate with sulfuric acid H 2 SO 4 Leaching, add pure water and sulfuric acid during the leaching process, so that lithium sulfate Li in the leaching solution 2 SO 4 The content is 90g / L, the pH of the leaching solution is 2.8, and the Ca 129mg / L, Mg 138mg / L, and Fe 159mg / L in the leaching solution.

[0056] (2) Add lithium hydroxide LiOH liquid to adjust the pH to about 7.0, and add lithium carbonate Li at 60~70°C 2 CO 3 Powder, the amount of lithium carbonate added is 1.1 times the amount required for the theoretical removal of calcium, magnesium and iron. Add sulfuric acid or lithium hydroxide to control the pH at about 7.0, and react for 20 minutes. F...

Embodiment 2

[0062] Preparation of high-purity lithium hydroxide from industrial grade lithium carbonate

[0063] Industrial grade lithium carbonate composition: Li 2 CO 3 98.21%, Na 2 O 0.31%, CaO 0.32%, SO 4 2— 0.58%, Fe 2 o 3 0.41%, MgO 0.29%, salt and inclusions 0.035%.

[0064] (1) Add industrial grade lithium carbonate to sulfuric acid H 2 SO 4 Carry out leaching, add pure water and sulfuric acid H during the leaching process 2 SO 4 , so that lithium sulfate Li in the leaching solution 2 SO 4 The content is 110g / L, the pH of the leaching solution is 3.2, and the Ca139mg / L, Mg126mg / L, and Fe167mg / L in the leaching solution.

[0065] (2) Add lithium hydroxide LiOH liquid to adjust pH=7.2, and add lithium carbonate Li at 60~70°C 2 CO 3 Powder, the amount of lithium carbonate added is 1.05 times the amount required to remove calcium, magnesium, and iron in theory, adding sulfuric acid or lithium hydroxide to control pH = 7.3, reacting for 20 minutes, filtering through a...

Embodiment 3

[0075] Preparation of high-purity lithium hydroxide from industrial grade lithium carbonate

[0076] Industrial grade lithium carbonate composition: Li 2 CO 3 98.22%, Na 2 O 0.22%, CaO 0.38%, SO 4 2— 0.42%, Fe 2 o 3 0.46%, MgO 0.39%, salt and inclusions 0.027%.

[0077] (1) Add pure water and sulfuric acid during the leaching process, so that the lithium sulfate content in the leaching solution is 125g / L, the ph of the leaching solution is 3.4, and the Ca 119mg / L, Mg 127mg / L, and Fe 135mg / L in the leaching solution.

[0078] (2) Add lithium hydroxide liquid to adjust pH = about 7.0, add lithium carbonate powder at 60~70°C, the amount of lithium carbonate added is 1.1 times the amount required to remove calcium, magnesium, and iron theoretically, add sulfuric acid or hydroxide Lithium controls the pH=7.0, reacts for 20 minutes, and filters through a plate and frame filter press. The impurity content in the filtrate is calcium 14mg / L, magnesium 10.6mg / L, Fe9.4mg / L, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com