Hydroxyl-functionalized carbon nano tube-reinforced pantograph pan and preparation method thereof

A technology of pantograph slides and carbon nanotubes, which is applied in the field of hydroxyl-functionalized carbon nanotube-reinforced pantograph slides and its preparation, which can solve the problems of poor combination of asphalt and aggregates, so as to prevent agglomeration and improve heat resistance performance, the effect of reducing the resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

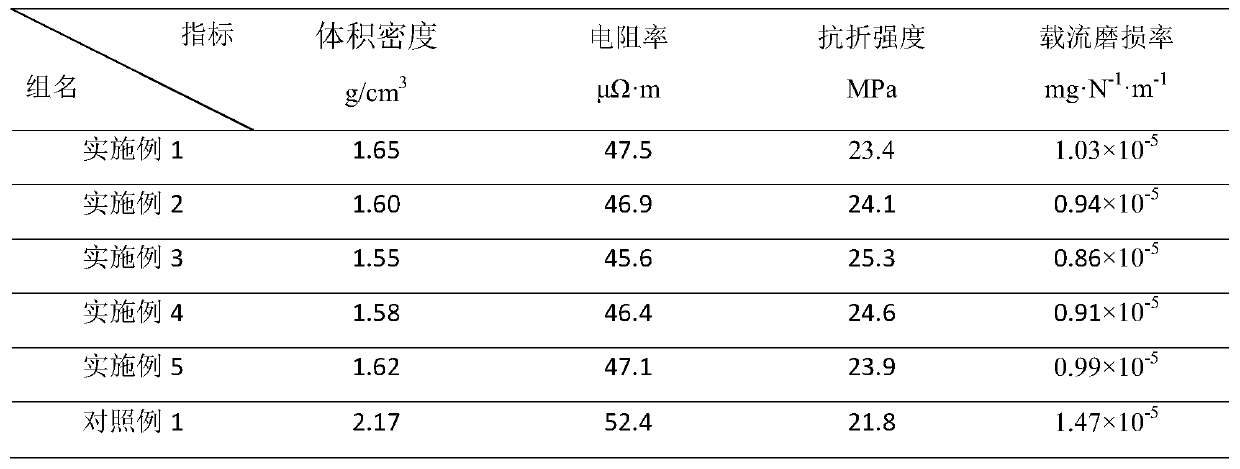

Examples

Embodiment 1

[0029] The hydroxyl-functionalized carbon nanotube-reinforced pantograph slide of this embodiment includes: by weight, 25 parts of pitch coke, 15 parts of petroleum coke, 15 parts of modified coal tar pitch, 8 parts of artificial graphite powder and hydroxyl-functionalized multi-wall 3 parts carbon nanotubes. Wherein, the hydroxyl functionalized multi-walled carbon nanotubes have a length of 5 μm.

[0030] The preparation method of the hydroxyl-functionalized carbon nanotube-reinforced pantograph sliding plate of this embodiment includes:

[0031] (1) After mixing the hydroxyl-functionalized carbon nanotubes with water, ultrasonically disperse them, and then dry them under vacuum conditions. The vacuum drying temperature is 80 ° C, and the drying time is 1 h;

[0032] (2) Mix and knead the dried hydroxyl-functionalized carbon nanotubes with modified coal tar pitch, heat up and melt, cool and solidify, and then crush and grind to obtain primary powder; wherein, the reaction co...

Embodiment 2

[0037] The hydroxyl-functionalized carbon nanotube-reinforced pantograph slide of this embodiment includes: in parts by weight, 35 parts of pitch coke, 20 parts of petroleum coke, 20-40 parts of modified coal tar pitch, 10 parts of artificial graphite powder and hydroxyl-functionalized 4 parts of multi-walled carbon nanotubes. Among them, the hydroxyl functionalized multi-walled carbon nanotubes have a length of 7 μm.

[0038] The preparation method of the hydroxyl-functionalized carbon nanotube-reinforced pantograph sliding plate of this embodiment includes:

[0039] (1) After mixing the hydroxyl-functionalized carbon nanotubes with water, ultrasonically disperse them, and then dry them under vacuum conditions; wherein, the vacuum drying temperature is 80° C., and the drying time is 1.5 hours;

[0040] (2) Mix and knead the dried hydroxyl-functionalized carbon nanotubes with modified coal tar pitch, heat up and melt, cool and solidify, and then crush and grind to obtain primar...

Embodiment 3

[0045] The hydroxyl-functionalized carbon nanotube-reinforced pantograph slide of this embodiment includes: by weight, 45 parts of pitch coke, 25 parts of petroleum coke, 25 parts of modified coal tar pitch, 13 parts of artificial graphite powder and hydroxyl-functionalized multi-wall 5 parts of carbon nanotubes. Wherein, the hydroxyl functionalized multi-walled carbon nanotubes have a length of 10 μm.

[0046] The preparation method of the hydroxyl-functionalized carbon nanotube-reinforced pantograph sliding plate of this embodiment includes:

[0047] (1) After mixing the hydroxyl-functionalized carbon nanotubes with water, ultrasonically disperse them, and then dry them under vacuum conditions. The vacuum drying temperature is 90° C., and the drying time is 2 hours;

[0048] (2) Mix and knead the dried hydroxyl-functionalized carbon nanotubes with modified coal tar pitch, heat up and melt, cool and solidify, and then crush and grind to obtain primary powder; wherein, the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com