Photocatalytic self-cleaning fabric and preparation method thereof

A self-cleaning and photocatalytic technology, which is applied in rayon manufacturing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of unsustainable functionality, inability to fully meet the needs of photocatalytic self-cleaning, and low washing fastness. achieve a strong combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

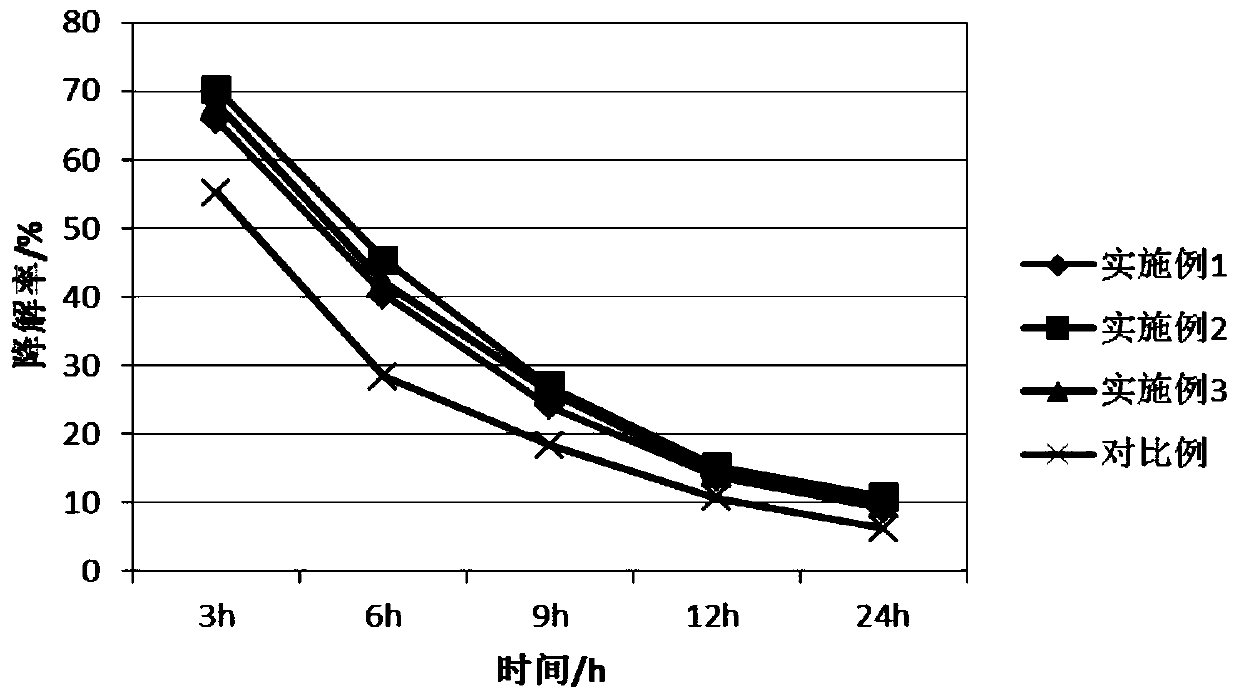

Examples

Embodiment 1

[0025] A photocatalytic self-cleaning fabric, the main components and their corresponding parts by mass are as follows: 65 parts of polyvinyl chloride, 10 parts of polyethylene terephthalate, 4 parts of silver-loaded nano-TiO2, and nano-SiO 2 2 parts, 2 parts of disodium hydrogen phosphate dodecahydrate, 3 parts of polystyrene sulfonate, 3 parts of cellulose ester, 8 parts of butyl benzyl phthalate, 2 parts of nano zinc oxide, nano cuprous oxide 2 parts, 0.1 part of defoamer, 0.4 part of chitosan, 0.3 part of emulsifying wetting agent, 2 parts of sodium alginate, 0.5 part of glycerin rosin ester.

[0026] The preparation method of above-mentioned photocatalytic self-cleaning fabric, comprises the steps:

[0027] (1) Weigh the raw materials according to the formula, and first put the silver-loaded nano-TiO 2 Dissolve in water, stir for 10min, then add nano-SiO 2 , nano-zinc oxide, nano-cuprous oxide, continue to stir for 20 minutes, transfer to the reaction kettle, react at ...

Embodiment 2

[0031] A photocatalytic self-cleaning fabric, the main components and their corresponding parts by mass are as follows: 70 parts of polyvinyl chloride, 13 parts of polyethylene terephthalate, silver-loaded nano-TiO 2 8 parts, nano-SiO 2 5 parts, 3 parts of disodium hydrogen phosphate dodecahydrate, 4 parts of polystyrene sulfonate, 3 parts of cellulose ester, 10 parts of butyl benzyl phthalate, 3 parts of nano zinc oxide, nano cuprous oxide 3 parts, 0.2 parts of defoamer, 1 part of chitosan, 0.8 parts of emulsifying wetting agent, 4 parts of sodium alginate, 1 part of glycerin rosin ester.

[0032] The preparation method of above-mentioned photocatalytic self-cleaning fabric, comprises the steps:

[0033] (1) Weigh the raw materials according to the formula, and first put the silver-loaded nano-TiO 2 Dissolve in water, stir for 20min, then add nano-SiO 2 , nano-zinc oxide, nano-cuprous oxide, continue to stir for 25 minutes, move into the reaction kettle, react at 200 ° C...

Embodiment 3

[0037] A photocatalytic self-cleaning fabric, the main components and their corresponding parts by mass are as follows: 80 parts of polyvinyl chloride, 15 parts of polyethylene terephthalate, silver-loaded nano-TiO 2 10 parts, Nano SiO 2 6 parts, 6 parts of disodium hydrogen phosphate dodecahydrate, 6 parts of polystyrene sulfonate, 5 parts of cellulose ester, 13 parts of butyl benzyl phthalate, 5 parts of nano zinc oxide, nano cuprous oxide 5 parts, 0.3 parts of defoamer, 1.2 parts of chitosan, 1 part of emulsifying wetting agent, 5 parts of sodium alginate, 1.5 parts of glycerin rosin ester.

[0038] The preparation method of above-mentioned photocatalytic self-cleaning fabric, comprises the steps:

[0039] (1) Weigh the raw materials according to the formula, and first put the silver-loaded nano-TiO 2 Dissolve in water, stir for 30min, then add nano-SiO 2 , nano-zinc oxide, nano-cuprous oxide, continue to stir for 30 minutes, move into the reaction kettle, react at 250...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com