Ordered mesopore catalyst layer and preparation method thereof, application of ordered mesopore catalyst layer, and film electrode and preparation method thereof

A technology of sequential mesoporous catalytic layer and catalytic layer, applied in battery electrodes, circuits, fuel cells, etc., can solve the problems of general dispersion, cumbersome steps, low utilization rate of precious metal catalysts, etc., to improve electrochemical performance and improve distribution. and the effect of uniformity of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

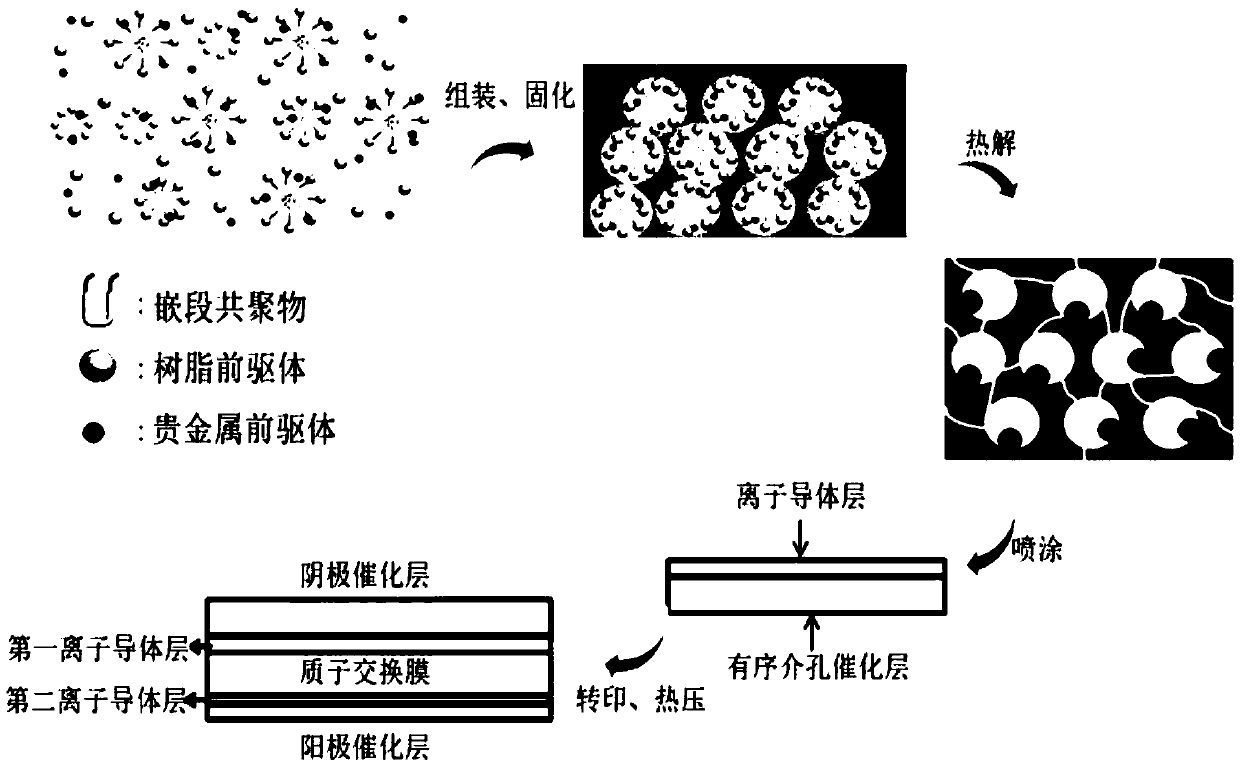

[0071] figure 1 It is a schematic diagram of the principle of the preparation method of the membrane electrode described in the specific embodiment of the present invention; it can be seen from the figure that the method includes firstly using a noble metal precursor, a resin precursor and a block copolymer to prepare an ordered mesoporous catalyst. layer, and then use the obtained ordered mesoporous catalytic layer to prepare a membrane electrode, the specific steps are as follows:

[0072] (1) Precious metal precursors, resin precursors and block copolymers are mixed and subjected to film-forming treatment and solvent evaporation to form self-assembly among the three, followed by heat treatment to cure the resin precursors;

[0073] (2) After the product of step (1) is carbonized, the soft template is pyrolyzed, and the noble metal is reduced simultaneously to obtain the ordered mesoporous catalytic layer;

[0074] (3) Select the ordered mesoporous catalytic layer as the ca...

Embodiment 1

[0077] The phenolic resin described in the present embodiment is prepared by the following method:

[0078] (a) Heat and melt 4g phenol at 42°C, then add 0.85g NaOH and stir;

[0079] (b) Add 6.88g (concentration is 37wt%) formaldehyde solution to the product obtained in step (a), then react in a 75°C water bath for 80min, and cool;

[0080] (c) adding hydrochloric acid to adjust the pH of the product obtained in step (b) to neutral, and centrifuging to obtain a phenolic resin.

[0081] Preparation of cathode catalytic layer:

[0082] (1) the phenolic resin obtained in step (c), 6.56gF127, 8.52g tetraammine platinum chloride are dissolved in the mixed solution of ethanol and water with a volume ratio of 1:1 to obtain the first mixed solution;

[0083] (2) Evaporate the solvent from the first mixed solution obtained in step (1) at 25°C to obtain a second mixed solution with a viscosity of 1500mPa·s, use a scraper with a specification of 50μm to scrape, obtain a wet film, and ...

Embodiment 2

[0093] The phenolic resin described in the present embodiment is prepared by the following method:

[0094] (a) Heat and melt 2.6g of phenol at 42°C, then add 0.55g of NaOH and stir;

[0095] (b) Add 4.47g (concentration is 37wt%) formaldehyde solution to the product obtained in step (a), then react in 80°C water bath for 60min, and cool;

[0096] (c) adding hydrochloric acid to adjust the pH of the product obtained in step (b) to neutral, stirring and then standing still for liquid separation to obtain a phenolic resin.

[0097] Preparation of cathode catalytic layer:

[0098] (1) Dissolving the phenolic resin obtained in step (c), 4.26g F127, and 6.18g ammonium chloroplatinite in a mixed solution of water and isopropanol at a volume ratio of 2:1 to obtain the first mixed solution;

[0099] (2) Evaporate the solvent from the first mixed solution obtained in step (1) at 25°C to obtain a second mixed solution with a viscosity of 2500mPa·s, use a scraper with a specification o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

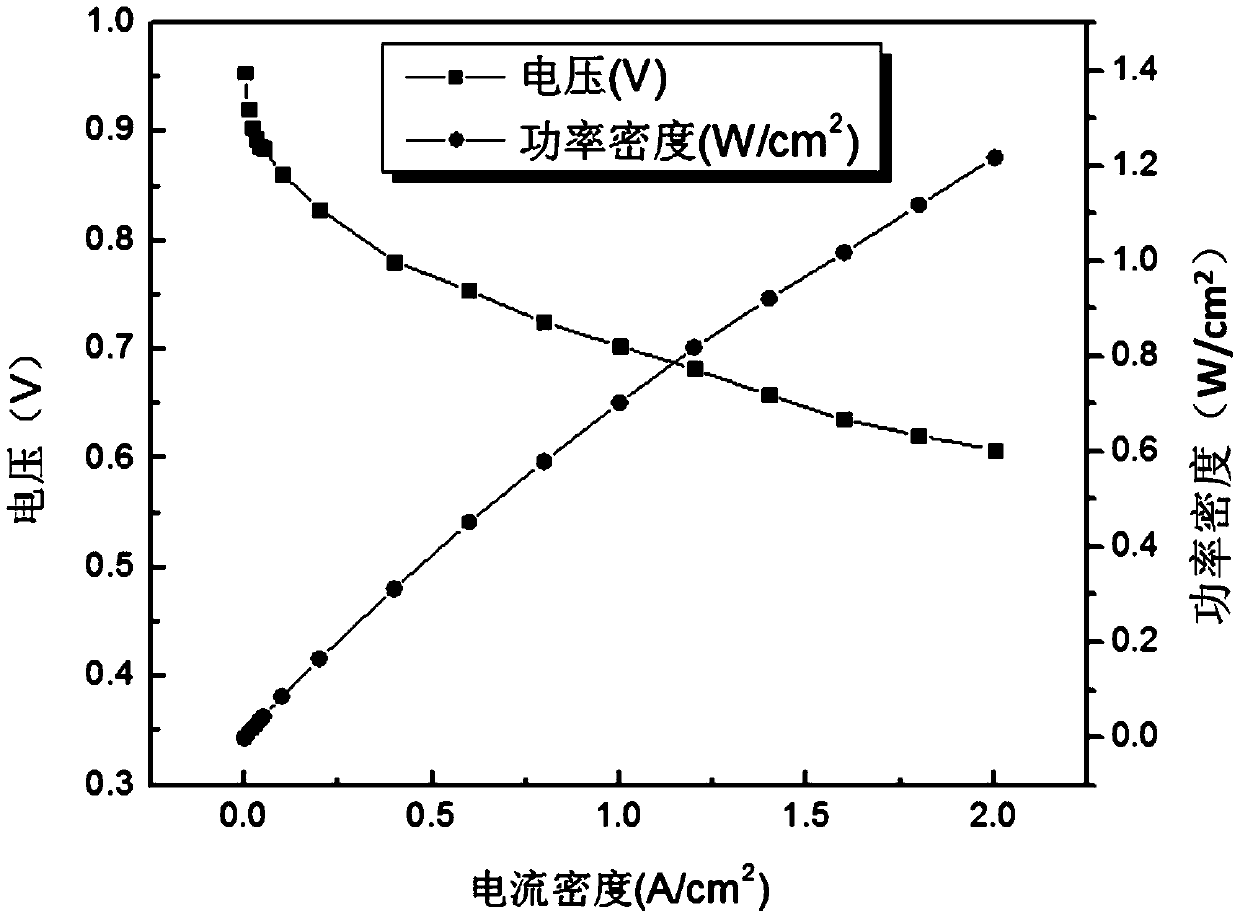

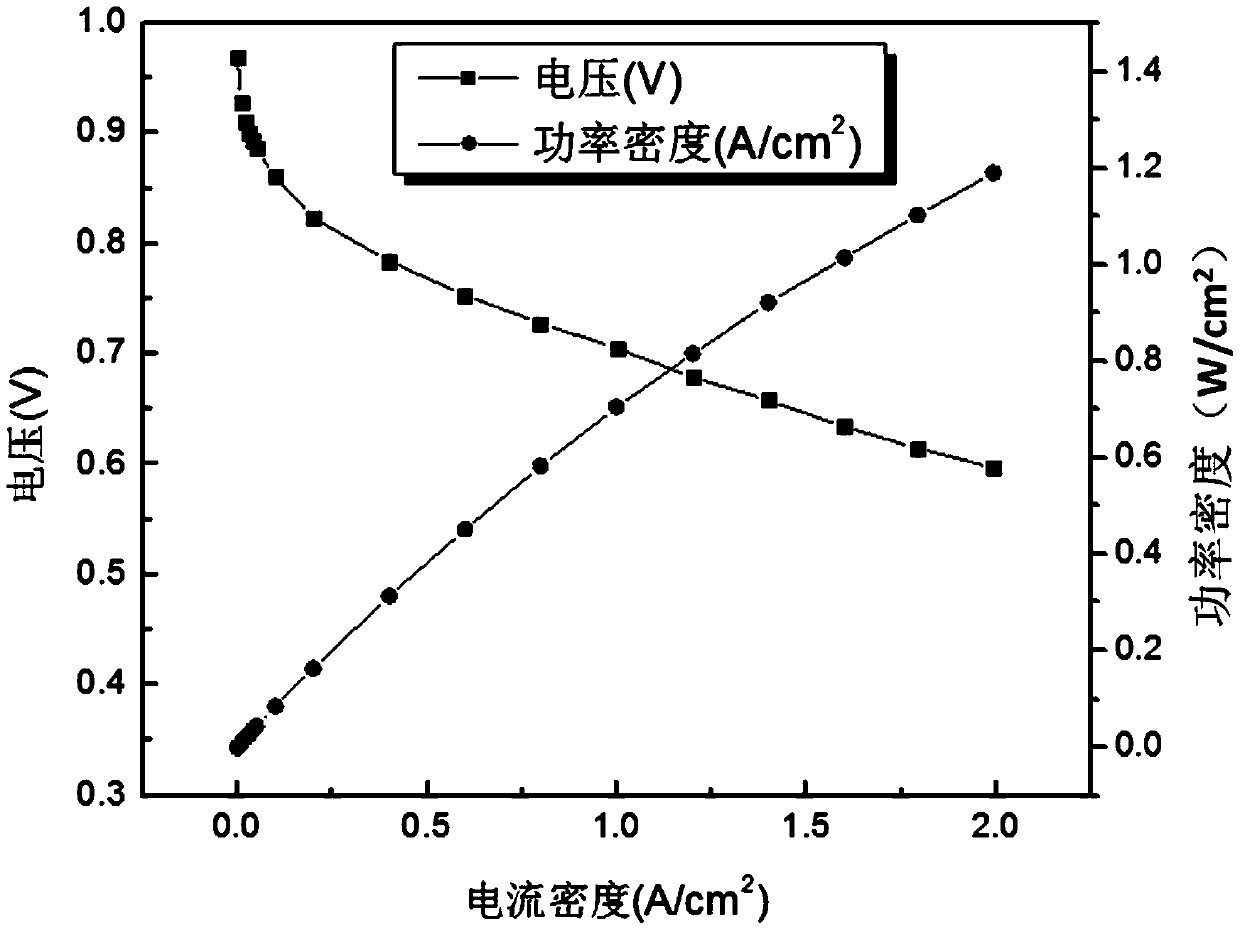

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com