Method for carrying out electron beam/ion beam focusing etching and microscopic imaging on non-conductive substrate

A technology of ion beam focusing and microscopic imaging, which is applied in the direction of microstructure technology, microstructure devices, and manufacturing microstructure devices, etc., which can solve problems such as inconvenient research and application, blurred imaging, and unsatisfactory requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

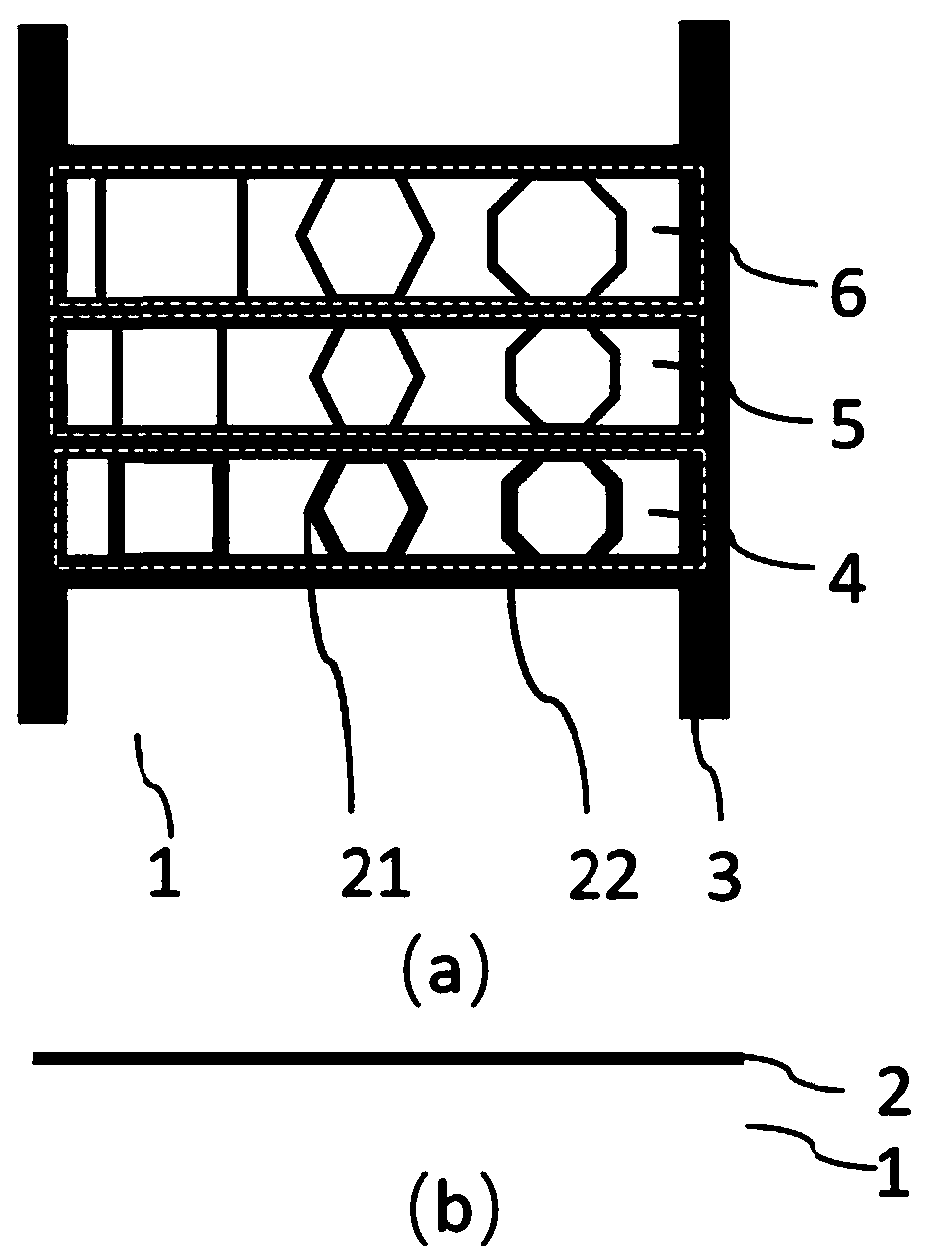

[0032] In this embodiment, the method for performing electron beam / ion beam focused etching and microscopic imaging on a non-conductive substrate includes the following steps:

[0033] S1 Design the shape and size of the photolithography mask;

[0034] S2 performing photolithographic treatment on the non-conductive substrate;

[0035] S3 performing metal coating treatment on the photolithographically processed non-conductive substrate to form a metal strip;

[0036] S4 develops the coated non-conductive substrate to become a sample;

[0037] S5 conducts grounding treatment on the metal belt;

[0038] S6 vacuumizes the sample;

[0039] S7 focuses on the metal strip of the sample, selects the electron beam current, and adjusts the sample stage to the sample area to be engraved after the imaging is clear;

[0040] S8 imports or draws the morphology of the micro-nano structure to be etched, and performs FIB or EBL etching and imaging on the sample after setting parameters.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com