Preparation method of humic acid layer sheet-based bimetal MoFs composite powder

A composite powder and bimetallic technology, which is applied in the cross field of energy storage materials and synthetic chemistry, can solve the problems of serious environmental pollution, application limitations, cumbersome synthesis process, etc., and achieve good rate characteristics, good cycle stability, and high ratio The effect of capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

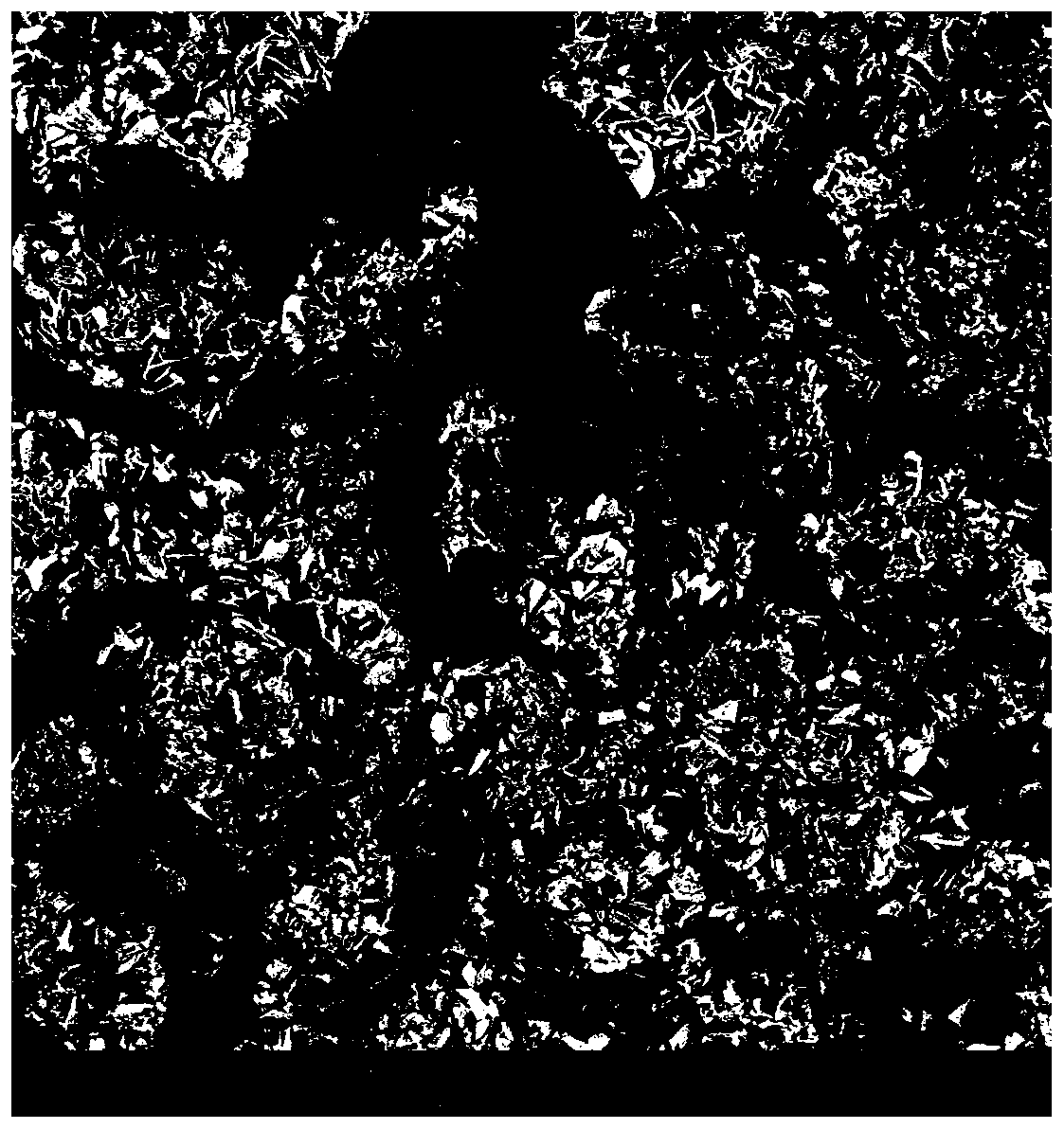

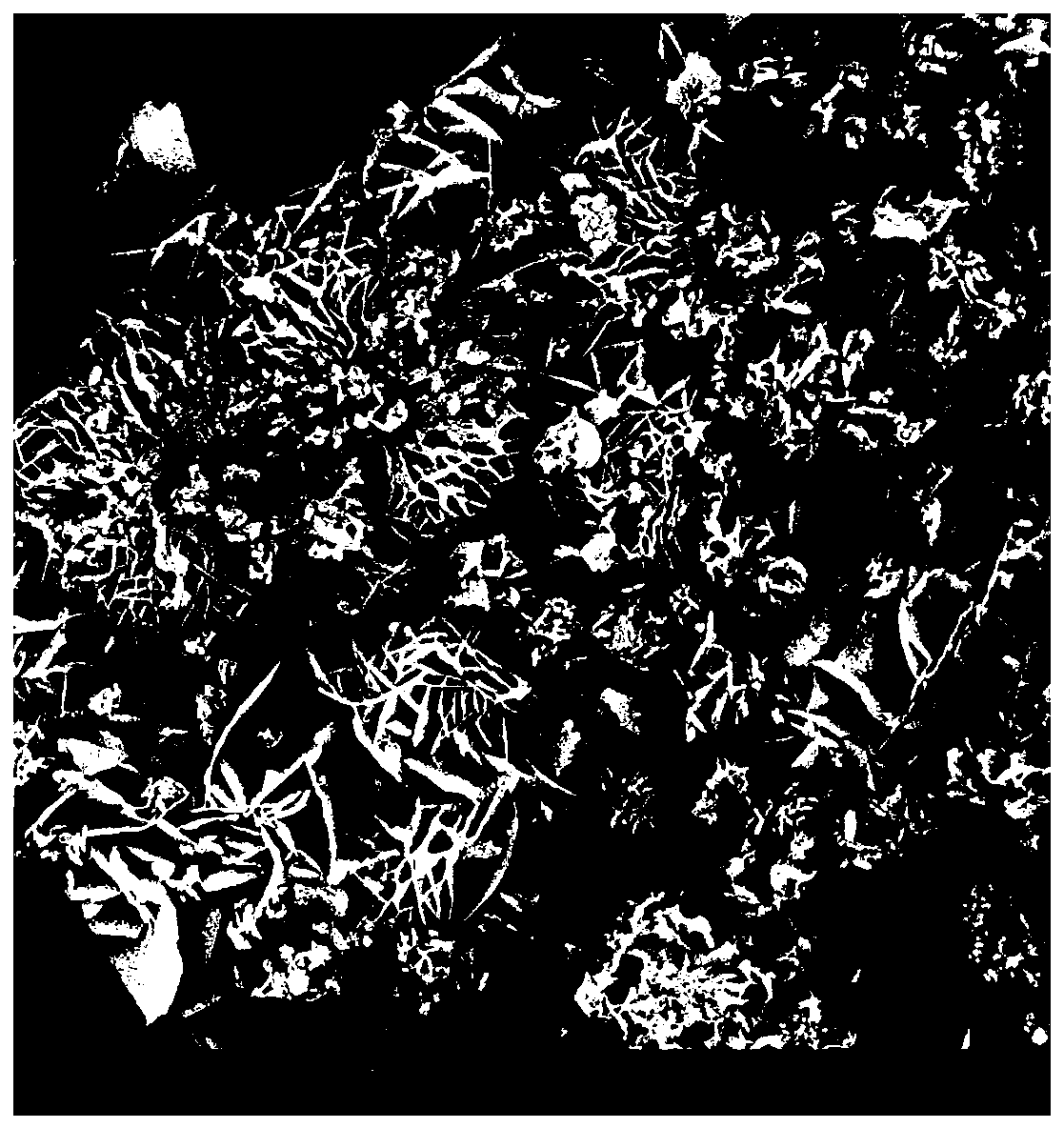

Image

Examples

Embodiment 1

[0034] The preparation method of the humic acid-layer sheet-based bimetallic MOFs composite powder in this embodiment specifically includes the following steps:

[0035] Step 1. Dissolve 22mg of sodium humate in 20mL of deionized water, filter with qualitative filter paper to remove large particles, and obtain suspension A;

[0036] Step 2. Add 43.5 mg of nickel nitrate hexahydrate and 43.5 mg of cobalt nitrate hexahydrate into 10 mL of deionized water, and stir evenly to obtain solution B;

[0037] Step 3. Mix the suspension A in the above step 1 with the solution B in the step 2, first ultrasonically treat it for 40 minutes, then conduct a hydrothermal reaction at 190°C for 12h, and cool the material after the hydrothermal reaction to room temperature (25°C) After ultrasonic treatment for 20min, suspension C was obtained; the frequency of ultrasonic treatment was 60KHz, and the power was 180W;

[0038]Step 4. Disperse 24 mg of 4,4'-biphenyl dicarboxylic acid in 30 mL of dei...

Embodiment 2

[0043] The preparation method of the humic acid-layer sheet-based bimetallic MOFs composite powder in this embodiment specifically includes the following steps:

[0044] Step 1. Dissolve 22mg of sodium humate in 22mL of deionized water, filter with qualitative filter paper to remove large particles, and obtain suspension A;

[0045] Step 2. Add 48.4 mg of nickel nitrate hexahydrate and 24.2 mg of cobalt nitrate hexahydrate into 10 mL of deionized water, and stir evenly to obtain solution B;

[0046] Step 3. Mix the suspension A in the above step 1 with the solution B in the step 2, first ultrasonically treat it for 45 minutes, then conduct a hydrothermal reaction at 150°C for 11 hours, and cool the material after the hydrothermal reaction to room temperature (25°C) After ultrasonic treatment for 25min, suspension C was obtained; the frequency of ultrasonic treatment was 50KHz, and the power was 200W;

[0047] Step 4. Disperse 18 mg of 4,4'-biphenyl dicarboxylic acid in 30 mL ...

Embodiment 3

[0052] The preparation method of the humic acid-layer sheet-based bimetallic MOFs composite powder in this embodiment specifically includes the following steps:

[0053] Step 1. Dissolve 22mg of sodium humate in 26mL of deionized water, filter with qualitative filter paper to remove large particles, and obtain suspension A;

[0054] Step 2. Add 19.3 mg of nickel nitrate hexahydrate and 38.7 mg of cobalt nitrate hexahydrate into 10 mL of deionized water, and stir evenly to obtain solution B;

[0055] Step 3. Mix the suspension A in the above step 1 with the solution B in the step 2, first ultrasonically treat it for 35 minutes, then conduct a hydrothermal reaction at 170°C for 10 hours, and cool the material after the hydrothermal reaction to room temperature (25°C) After ultrasonic treatment for 15 minutes, suspension C was obtained; the frequency of ultrasonic treatment was 40KHz, and the power was 150W;

[0056] Step 4. Disperse 12 mg of 4,4'-biphenyl dicarboxylic acid in 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com