Production technology of high-elongation cold-rolled ribbed bar

A technology of cold-rolled ribbed steel bar and production process, applied in the field of cold-rolled steel bar, can solve the problems of backward processing technology of cold-rolled steel bar, poor process fluency of cold-rolled steel bar, poor performance of steel bar, etc., so as to ensure fluency and improve fluency. , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

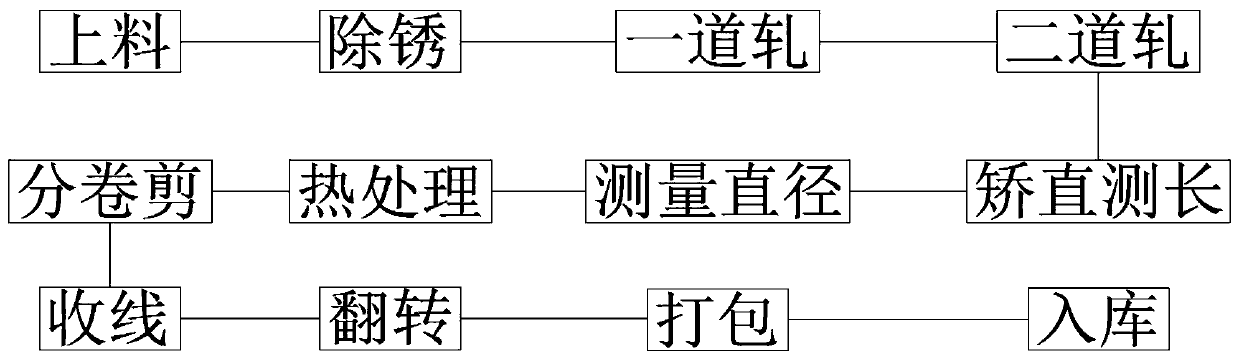

[0057] like figure 1 Shown, a kind of high-ductility cold-rolled ribbed steel bar production process comprises feeding operation, steel bar processing and finished product collection, and described steel bar processing comprises the following steps:

[0058] One rolling process: the steel bars pass through a rolling mill, which reduces the diameter of the steel bars and rolls them flat.

[0059]Two-pass rolling process: pass the steel bars rolled in one pass through two rolling mills, and the two rolling mills round and reduce the diameter of the steel bars rolled in one pass, and the diameter reduction ratio is 0.6-0.8.

[0060] Heat treatment process: Tempering the steel bars treated in the second rolling process, heat treatment at a temperature of 580-650°C for 0.8-2s, and the treated steel bars are naturally cooled in the air.

[0061] The first rolling process does not reduce the diameter of the steel bar, but just flattens the steel bar. By rolling the steel bar flat, t...

Embodiment 2

[0063] like figure 1 Shown, a kind of high-ductility cold-rolled ribbed steel bar production process comprises feeding operation, steel bar processing and finished product collection, and described steel bar processing comprises the following steps:

[0064] One rolling process: the steel bars pass through a rolling mill, which reduces the diameter of the steel bars and rolls them flat.

[0065] Two-pass rolling process: pass the steel bars rolled in one pass through two rolling mills, and the two rolling mills round and reduce the diameter of the steel bars rolled in one pass, and the diameter reduction ratio is 0.6-0.8.

[0066] Heat treatment process: Tempering the steel bars treated in the second rolling process, heat treatment at a temperature of 580-650°C for 0.8-2s, and the treated steel bars are naturally cooled in the air.

[0067] The first rolling process does not reduce the diameter of the steel bar, but just flattens the steel bar. By rolling the steel bar flat, ...

Embodiment 3

[0077] like figure 1 Shown, a kind of high-ductility cold-rolled ribbed steel bar production process comprises feeding operation, steel bar processing and finished product collection, and described steel bar processing comprises the following steps:

[0078] One rolling process: the steel bars pass through a rolling mill, which reduces the diameter of the steel bars and rolls them flat.

[0079] Two-pass rolling process: pass the steel bars rolled in one pass through two rolling mills, and the two rolling mills round and reduce the diameter of the steel bars rolled in one pass, and the diameter reduction ratio is 0.6-0.8.

[0080] Heat treatment process: Tempering the steel bars treated in the second rolling process, heat treatment at a temperature of 580-650°C for 0.8-2s, and the treated steel bars are naturally cooled in the air.

[0081] The first rolling process does not reduce the diameter of the steel bar, but just flattens the steel bar. By rolling the steel bar flat, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com