Special filler for nitrate nitrogen removal using sulfur-iron coupling technology, and preparation method thereof

A nitrate nitrogen technology, which is applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of inability to ensure full utilization of fillers, sludge expansion, etc. High mechanical strength and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a special packing for removing nitrate nitrogen by sulfur-iron coupling technology, comprising the following steps:

[0029] Step 1. Prepare surface modifier, surfactant and a mixed solution with several sections, wherein the concentration of surface modifier is 5-10g / L, mix it with sulfur particles evenly, and let it stand for infiltration;

[0030] Step 2, taking out the sulfur granules obtained in step 1 and drying to obtain sulfur granules with a surface modifying agent on the surface;

[0031] Step 3: Mix the sulfur granules coated with the surface modifying agent prepared in step 2 evenly with limestone granules, pyrite granules and denitrifying bacteria immobilized granules.

Embodiment 1

[0033] The filler of the invention is used to treat simulated nitrate sewage. Mix sulfur particles, limestone particles, pyrite particles and denitrifying bacteria immobilized particles with particle diameters of 5mm, 4mm, 3mm and 3mm evenly according to the mass ratio of 5:1:2:4, and put them in the reactor. Sodium nitrate is added to tap water to prepare water with a nitrate nitrogen concentration of 60mg / L to simulate the water quality of sewage. The raw water is injected into the reactor through a peristaltic pump, and the sewage and fillers are continuously stirred in the reactor. The residence time of sewage in the reactor is After 60 minutes, it was detected that the content of nitrate nitrogen in the water was lower than 3mg / L, and the removal rate was greater than 95%. After a long-term running test, the quality of the effluent is stable and can meet the discharge standard. The monitoring data are shown in Table 1:

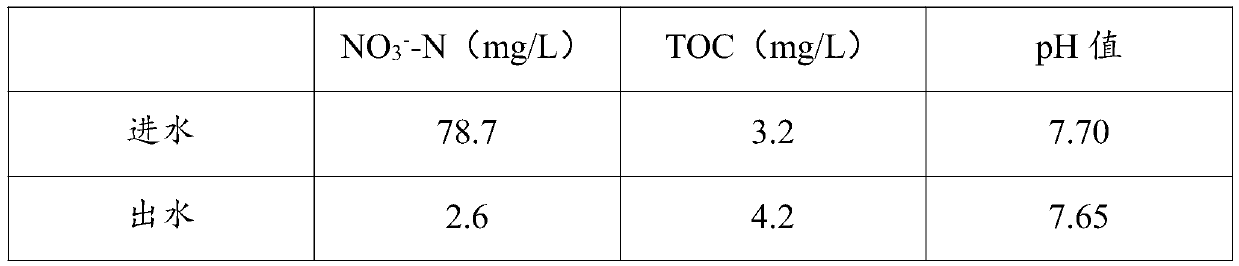

[0034] Table 1 is the detection data of embodiment...

Embodiment 2

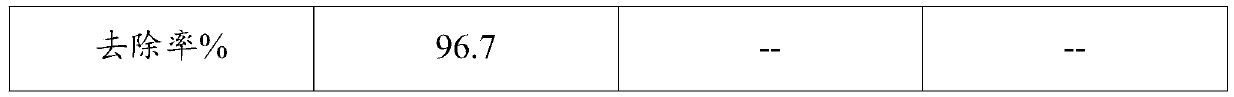

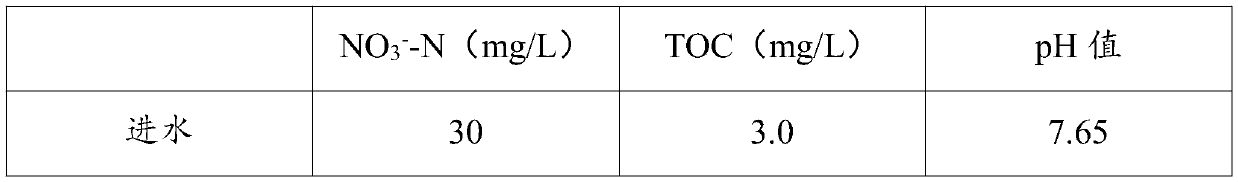

[0037] The filler of the invention is used to treat simulated nitrate sewage. The sulfur particles, limestone particles, pyrite particles and denitrifying bacteria immobilized particles with particle diameters of 5mm, 3mm, 3mm and 4mm were mixed evenly according to the mass ratio of 6:1.5:1.5:5, and packed into the reactor. Sodium nitrate is added to tap water to make water with a concentration of nitrate nitrogen of 80mg / L to simulate the water quality of sewage. The raw water is injected into the reactor through a peristaltic pump, and the sewage and filler are continuously stirred in the reactor. The residence time of sewage in the reactor is After 60 minutes, it was detected that the content of nitrate nitrogen in the water was lower than 3mg / L, and the removal rate was greater than 95%. After long-term running and testing, the quality of the effluent is stable and can meet the discharge standards. The monitoring data are shown in Table 2:

[0038] Table 2 is the detectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com