Diversified microbial fertilizer produced by fermentation of corn straws and preparation method of diversified microbial fertilizer

A technology for microbial fertilizer and corn stalks, applied in the preparation of organic fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve the problems of reducing the quality of crops, increasing the cost of farming, and easily producing pests and diseases, and achieves the improvement of product quality. The effect of the duration of high temperature in the stack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of described multivariate microbial fertilizer, comprises the steps:

[0040] Step 1. Mix corn stalks, cow dung, mushroom dregs and corn flour, and spray a quarter of the microbial agent, mix and bury them in a greenhouse, adjust the moisture content to 68-73%, and carry out aerobic treatment for 62 days For fermentation, turn the pile once every 4 days for the first 32 days, add a small amount of tap water each time when turning the pile, and keep the moisture content at 68-73%. Turn the compost once every 10 days for 30 days. After the fermentation is completed, organic fertilizer is obtained;

[0041] Step 2. Put organic fertilizer, urea, superphosphate, potassium chloride and half of the remaining microbial agent into the coating machine, then add modified biochar and diatomaceous earth, and set the speed of the coating machine to 65r / min , stirred for 30 minutes, after the materials were fully mixed, evenly sprayed an aqueous solution of pol...

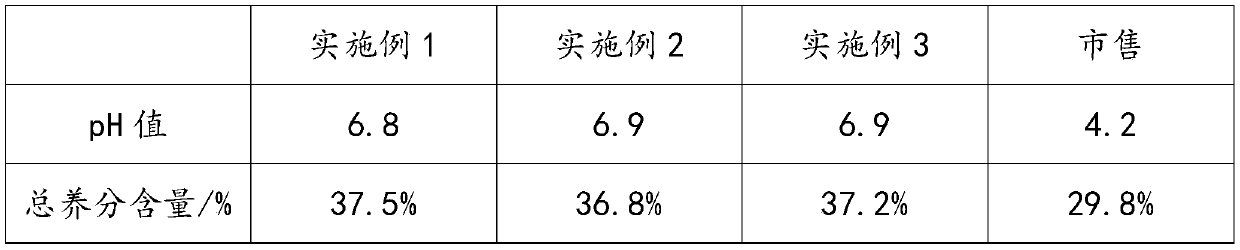

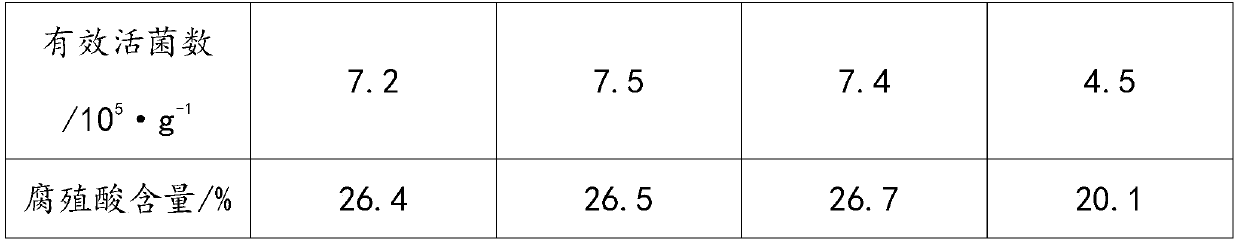

Embodiment 1

[0045] Corn stalks are fermented to produce multiple microbial fertilizers, which are made of the following raw materials in parts by weight: 50 parts of corn stalks, 40 parts of mushroom dregs, 4 parts of cow dung, 3 parts of microbial agents, 1 part of corn flour, 26 parts of urea, superphosphate 13 parts, 12 parts of potassium chloride, 17 parts of modified biochar, 5 parts of diatomaceous earth, 11 parts of polyvinyl alcohol aqueous solution, 100 parts of tap water;

[0046] Described multivariate microbial fertilizer is made by following steps:

[0047] Step 1. Mix corn stalks, cow dung, mushroom dregs and corn flour, and spray a quarter of the microbial agent, mix and bury them in a greenhouse, adjust the moisture content to 68%, and carry out aerobic fermentation for 62 days. Turn the pile once every 4 days for the first 32 days, add a small amount of tap water to keep the moisture content at 68% each time you turn the pile, spray a quarter of the microbial agent again ...

Embodiment 2

[0050] Corn stalks are fermented to produce multiple microbial fertilizers, which are made of the following raw materials in parts by weight: 55 parts of corn stalks, 45 parts of mushroom dregs, 4.5 parts of cow dung, 3.5 parts of microbial agents, 1.5 parts of corn flour, 29 parts of urea, superphosphate 14.5 parts, potassium chloride 13.5 parts, modified biochar 18.5 parts, diatomaceous earth 6 parts, polyvinyl alcohol aqueous solution 12 parts, tap water 150 parts;

[0051] Described multivariate microbial fertilizer is made by following steps:

[0052] Step 1. Mix corn stalks, cow dung, mushroom dregs and corn flour, and spray a quarter of the microbial agent, mix and bury them in a greenhouse, adjust the moisture content to 70%, and carry out aerobic fermentation for 62 days. Turn the pile once every 4 days for the first 32 days, add a small amount of tap water to keep the moisture content at 70% each time you turn the pile, and spray a quarter of the microbial agent agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com