Biochar-based organic fertilizer, preparation method thereof, and application of biochar-based organic fertilizer to crop planting

A biochar and organic fertilizer technology, applied in the preparation of organic fertilizers, the treatment of biological organic parts, organic fertilizers, etc., can solve the problems of lack of innovative support for the utilization of corn straw resources, the effect of fertilizer application is not obvious, and the straw resources are not fully utilized. , to achieve the effect of improving rhizosphere environment, high added value of products, improving structure and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

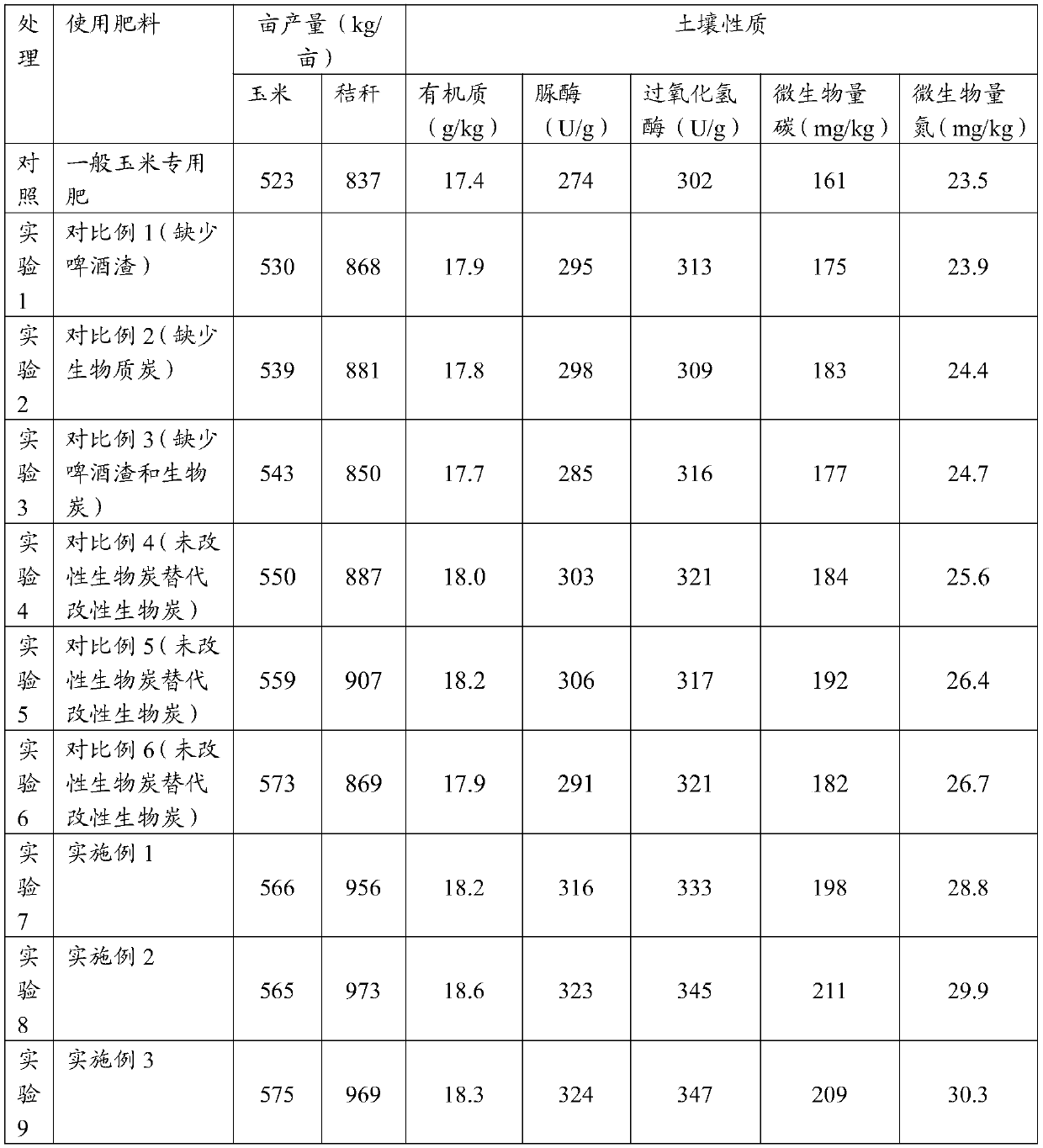

Examples

preparation example Construction

[0029] The raw materials of the biochar-based organic fertilizer provided by the invention include graphene / Mn / biomass charcoal. In parts by weight, the graphene / Mn / biomass char is preferably 16-19 parts, more preferably 17-18 parts. The preparation method of described graphene / Mn / biomass charcoal, comprises the following steps:

[0030] 1) mixing corn stalk residue powder and graphene to obtain a mixture;

[0031] 2) heating the mixture at 90-110° C. for 0.5-2 hours to obtain a heated product;

[0032] 3) mixing the heated product with manganese chloride, and carbonizing at 500-600° C. for 3-5 hours to obtain the primary graphene-modified biochar;

[0033] 4) removing the ash from the graphene-modified biochar primary product to obtain graphene / Mn / biomass charcoal.

[0034] In the present invention, the corn stalk residue powder is preferably obtained by removing attachments from corn stalks, crushing and sieving. The method for removing attachments from corn stalks is pr...

Embodiment 1

[0060] Raw material preparation

[0061] 1) Beer dregs pretreatment: Dehydrate and dry the beer dregs until the water content is less than 10%, put them in a pulverizer to pulverize them, and pass through a 20-mesh sieve to obtain pretreated beer dregs.

[0062] 2) Preparation method of corn stalk biochar

[0063] After the corn stalks were washed 4 times with water to remove surface adherents, they were air-dried for 2 days and dried overnight in an oven at 70°C. After crushing, they were passed through a 100 sieve and put in brown bottles for later use.

[0064] Instrument: Program-controlled muffle furnace.

[0065] Method: Oxygen-limited and temperature-controlled carbonization. Mix the above-mentioned corn stalk residue powder and graphene at a mass ratio of 200:1 and put them in a crucible to obtain a mixture; heat at 110°C for 0.5h, and the mass ratio of the heated product to manganese chloride is 100-1 Manganese chloride was added in the proportion, mixed evenly, an...

Embodiment 2

[0075] Raw material preparation:

[0076] 1) Beer dregs are decomposed: dehydrating and drying the beer dregs until the water content is less than 10%, putting them in a pulverizer to pulverize them, and passing through a 20-mesh sieve to obtain pretreated beer dregs.

[0077] 2) The preparation of corn stalk biochar, that is, the preparation of modified biochar. The preparation method is as follows: the corn stalks are washed 4 times with water to remove surface adherents, then air-dried for 2 days, dried overnight in an oven at 80°C, crushed, and dried for 80 Mesh sieve, put in a brown bottle and set aside.

[0078] Instrument: Program-controlled muffle furnace. Method: Oxygen-limited and temperature-controlled carbonization. Corn stalk residue powder and graphene passed through an 80-mesh sieve were mixed in a crucible at a mass ratio of 200:1 to obtain a mixture; heated at 110°C for 0.5h, and then mixed according to the mass ratio of the heated product to manganese chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com