Anti-static/conductive polyimide resin as well as preparation method and application thereof

A polyimide resin, conductive technology, applied in the field of polymer materials, can solve the problems of not meeting the antistatic/conductive performance requirements, unsatisfactory effect of multi-component copolymerized polyimide, unstable product performance, etc., to achieve excellent Anti-static or conductive performance, good conductivity, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

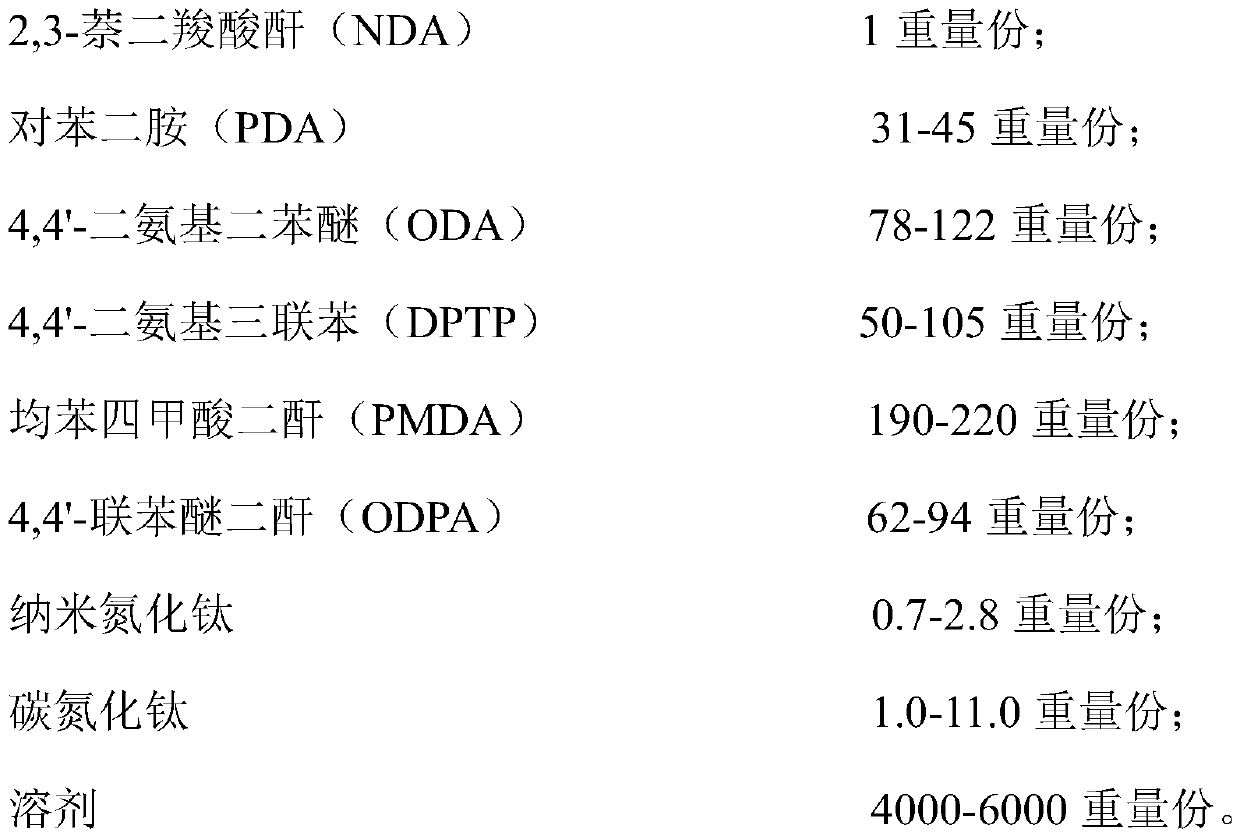

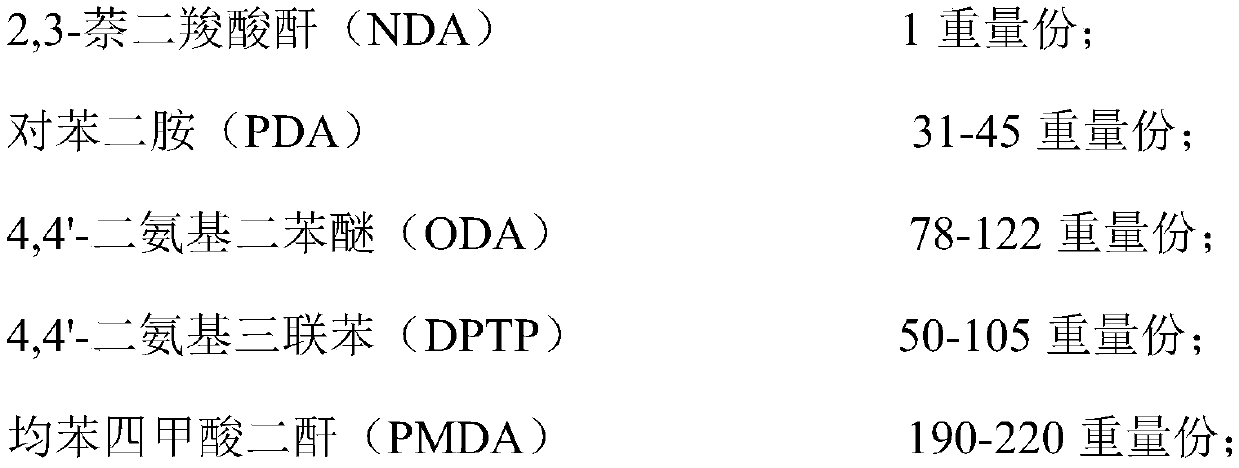

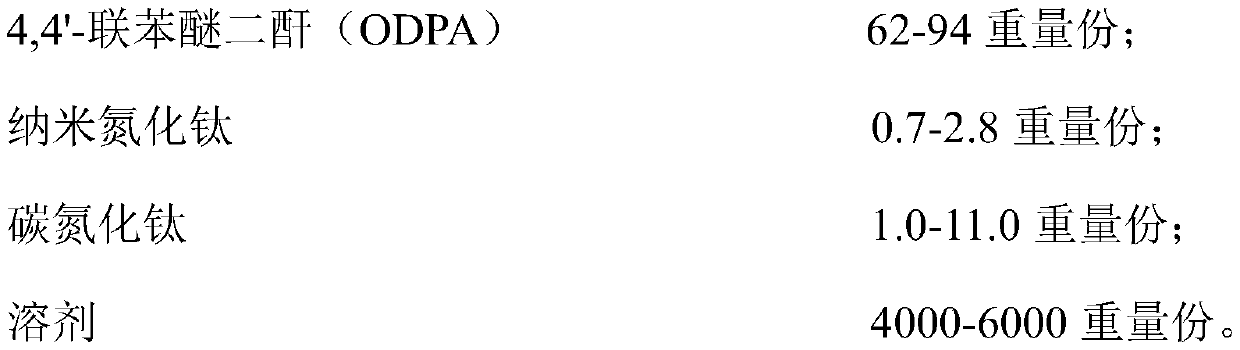

Method used

Image

Examples

Embodiment 1

[0044] Introduce high-purity nitrogen into the PTFE-lined anchor paddle type scraping wall stirring reactor equipped with high and low temperature cycle heating and cooling control device, reflux condenser and temperature sensor, and add 100.0kg of DMAC and 25.0kg of TMB after 10min , start stirring, set the temperature of the kettle to 0°C, wait until the temperature of the kettle reaches the set temperature, add 16.018kg of ODA, stir until it is completely dissolved, slowly add 8.725kg of PMDA within 5-6min, and keep the temperature for 90min to obtain Lower molecular weight amino-terminated alternating copolymer P(ODA-alt-PMDA);

[0045] Introduce high-purity nitrogen into the PTFE-lined anchor paddle type scraping wall stirring reactor equipped with high and low temperature cycle heating and cooling control device, reflux condenser and temperature sensor, and add 90.0kg of DMAC and 20.0kg of TMB after 10min , start stirring, set the temperature of the kettle to 5°C, wait u...

Embodiment 2

[0054] Introduce high-purity nitrogen into the PTFE-lined anchor paddle type scraping wall stirring reactor equipped with high and low temperature cycle heating and cooling control device, reflux condenser and temperature sensor, and add 150.0kg of DMSO and 50.0kg of TMB after 10min , start stirring, set the temperature of the kettle to 0°C, wait until the temperature of the kettle reaches the set temperature, add 20.023kg of ODA, stir until it is completely dissolved, slowly add 16.359kg of PMDA within 6-8min, and keep the temperature for 120min to obtain Lower molecular weight amino-terminated alternating copolymer P(ODA-alt-PMDA);

[0055] Introduce high-purity nitrogen into the PTFE-lined anchor paddle type scraping wall stirring reactor equipped with high and low temperature cycle heating and cooling control device, reflux condenser and temperature sensor, and add 100.0kg of DMSO and 20.0kg of TMB after 10min , start stirring, set the temperature of the kettle to 5°C, wai...

Embodiment 3

[0064] Introduce high-purity nitrogen into the PTFE-lined anchor paddle type scraping wall stirring reactor equipped with high and low temperature cycle heating and cooling control device, reflux condenser, and temperature sensor, and add 150.0kg of DMAC and 90.0kg of DMSO after 10 minutes and 60.0kg of TMB, start stirring, set the temperature of the kettle to 0°C, wait until the temperature of the kettle reaches the set temperature, add 24.028kg of ODA, stir until completely dissolved, within 12-15min, slowly add 21.812kg of PMDA, keep warm React for 240min to obtain the amino-terminated alternating copolymer P(ODA-alt-PMDA) of lower molecular weight;

[0065] Introduce high-purity nitrogen into the PTFE-lined anchor paddle type scraping wall stirring reactor equipped with high and low temperature cycle heating and cooling control device, reflux condenser, and temperature sensor, and add 75.0kg of DMAC and 45.0kg of DMSO after 10 minutes and 50.0kg of TMB, start stirring, set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com