High performance composite modified asphalt, and preparation method thereof

A composite modified asphalt, high-performance technology, applied in the direction of building components, building insulation materials, buildings, etc., can solve the three major indicators of easy agglomeration, modified asphalt and low temperature performance can not meet road technical requirements, modified asphalt performance Attenuation and other issues, to achieve the effect of short processing time, high temperature performance improvement, and low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The raw materials used were weighed according to the following weights: 82 parts of base asphalt, 1.5 parts of polyphosphoric acid, 3 parts of recycled polyethylene wax, 2 parts of rock asphalt, 1.5 parts of calcium carbonate, 8 parts of powdered styrene-butadiene rubber, and 2 parts of extracted oil.

[0030] The modified asphalt was prepared by the following steps: 1) The preparation method of component A: heat and melt the base asphalt at 160°C, add polyphosphoric acid and stir for 30min at 250r / min to complete the chemical modification. 2) The preparation method of component B: add recycled polyethylene wax, rock asphalt, filler, rubber, extracted oil, etc. into the twin-screw extruder according to a certain formula, and mix, heat, shear, shape, The pelletizing process prepares composite modifier pellets. 3) Add component B to component A at 160°C and stir for 4 hours at 250r / min to obtain the high-performance composite modified asphalt.

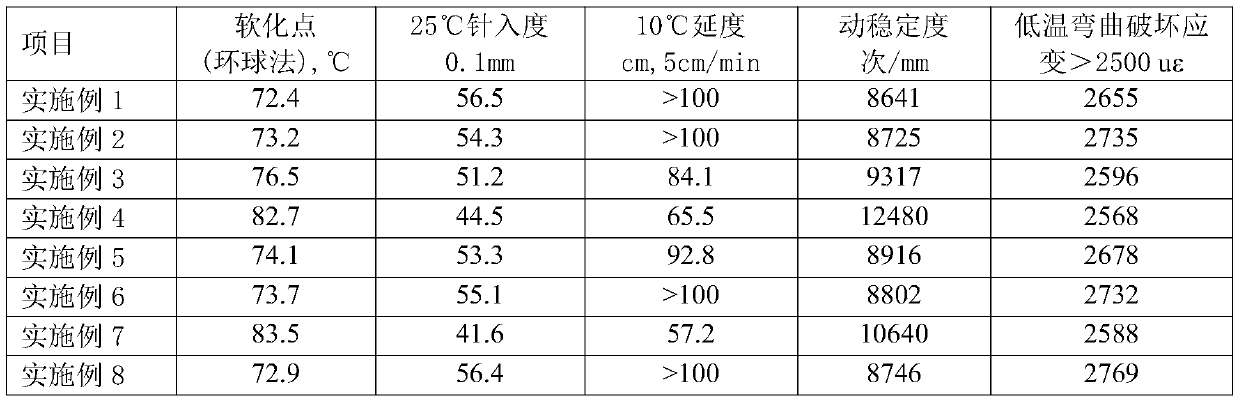

[0031] The technical indi...

Embodiment 2

[0033] The raw materials used were weighed according to the following weights: 86.5 parts of base asphalt, 0.5 parts of polyphosphoric acid, 3 parts of regenerated polyethylene wax, 3 parts of rock asphalt, 2 parts of carbon black, 1 part of natural rubber, and 4 parts of extracted oil.

[0034] The modified asphalt was prepared by the following steps: 1) The preparation method of component A: heat and melt the base asphalt at 130°C, add polyphosphoric acid and stir for 1 hour at 200r / min to complete the chemical modification. 2) The preparation method of component B: add recycled polyethylene wax, rock asphalt, filler, rubber, extracted oil, etc. into the twin-screw extruder according to a certain formula, and mix, heat, shear, shape, The pelletizing process prepares composite modifier pellets. 3) Add component B to component A at 130°C and stir for 2 hours at 200r / min to obtain the high-performance composite modified asphalt.

[0035] The technical indicators of the prepared ...

Embodiment 3

[0037] The raw materials used were weighed according to the following weights: 80 parts of base asphalt, 1.5 parts of polyphosphoric acid, 10 parts of regenerated polyethylene wax, 1 part of rock asphalt, 4 parts of carbon black, 2 parts of neoprene rubber, and 1.5 parts of extracted oil.

[0038] The modified asphalt was prepared by the following steps: 1) The preparation method of component A: heat and melt the base asphalt at 165°C, add polyphosphoric acid and stir for 20min at 250r / min to complete the chemical modification. 2) The preparation method of component B: add recycled polyethylene wax, rock asphalt, filler, rubber, extracted oil, etc. into the twin-screw extruder according to a certain formula, and mix, heat, shear, shape, The pelletizing process prepares composite modifier pellets. 3) Add component B to component A at 165°C and stir for 3 hours at 250r / min to obtain the high-performance composite modified asphalt.

[0039] The technical indicators of the prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com