Solid waste treatment system adopting plasma gasification

A plasma and treatment system technology, applied in the field of plasma combustion devices, can solve the problems of poor waste gas treatment effect and reduced generation efficiency, so as to prevent secondary damage and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

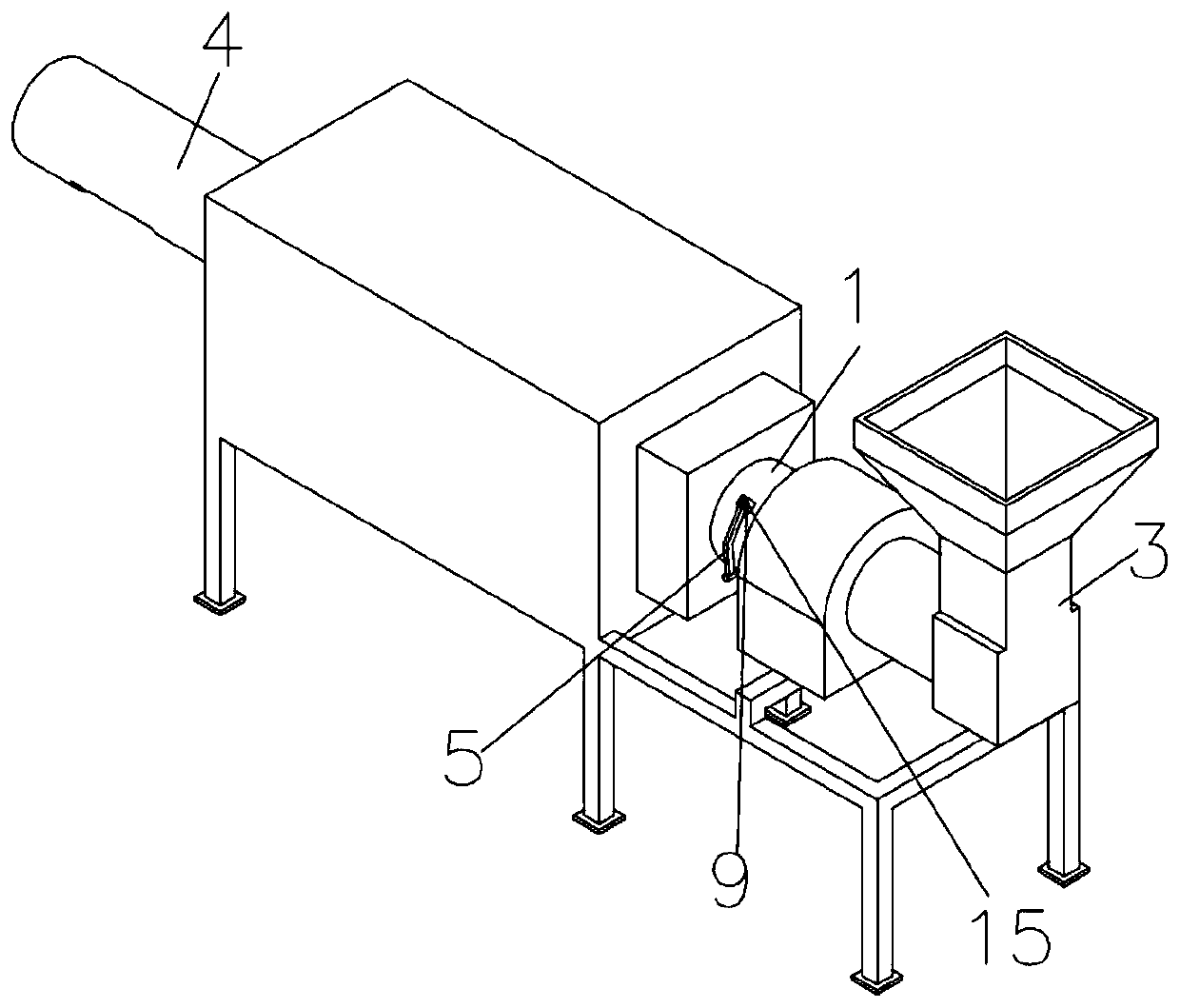

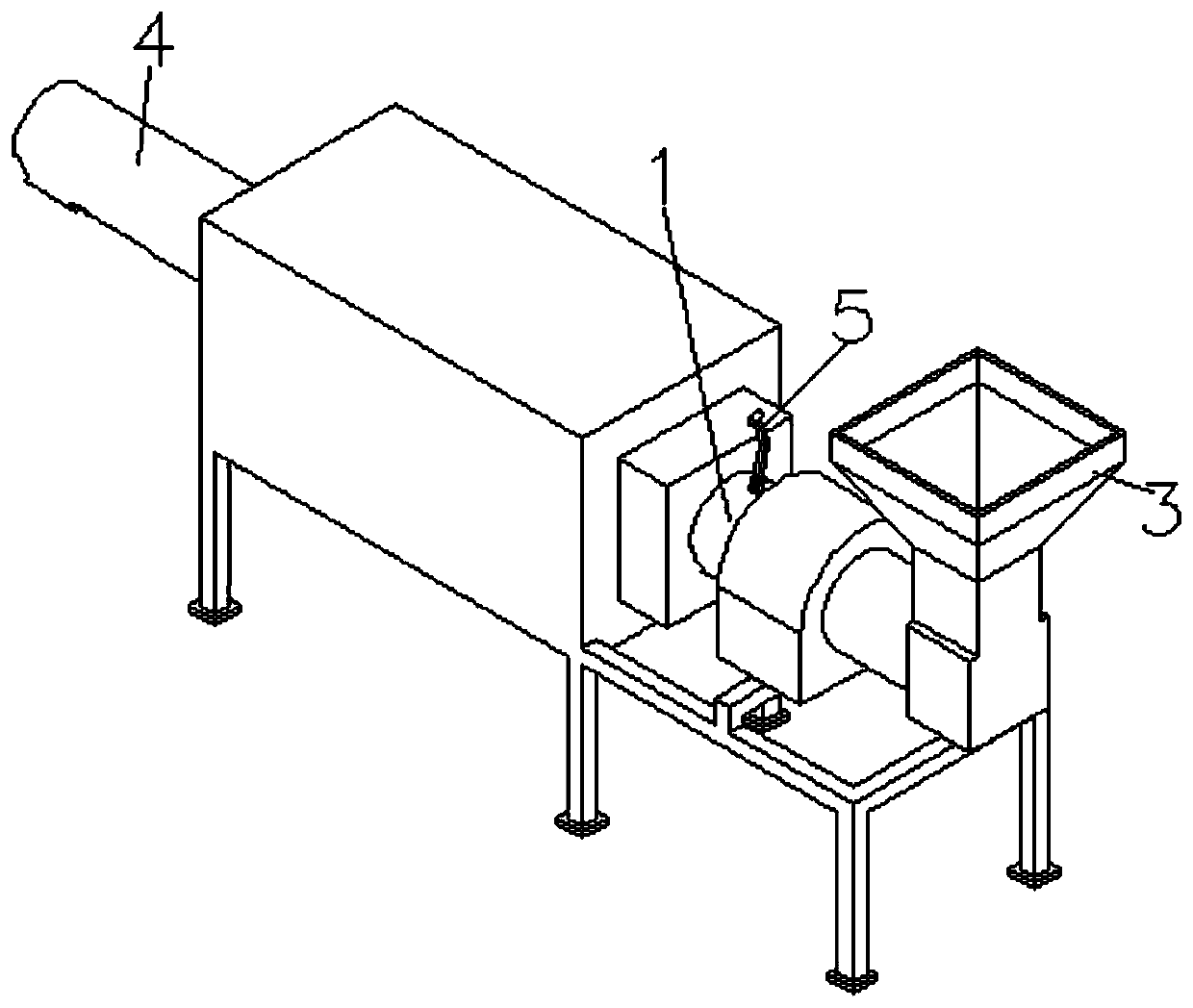

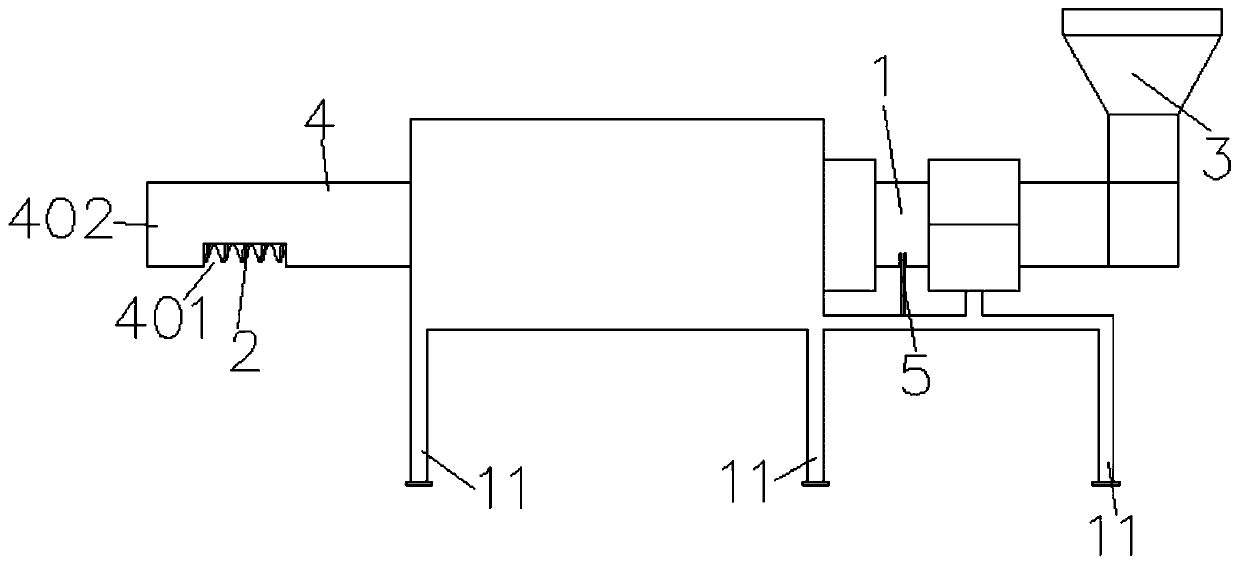

[0036] Such as Figure 1-8 As shown, a plasma gasification solid waste treatment system provided by the present invention includes a furnace body 1 and a drive assembly (not shown) that drives the furnace body 1 to rotate; specifically, the drive assembly can be a motor, etc., which can drive The furnace body 1 rotates; a charging device 3 located on one side of the furnace body 1 , and a discharge device 4 located on one side of the furnace body 1 . In this embodiment, the drive assembly can drive the furnace body 1 to rotate. When the furnace body 1 rotates, the ashes or solid waste on the inner wall of the furnace body 1 at the highest point of the worktable will automatically fall down by gravity, and some sticky Sticky ashes and solid waste cannot fall. The plasma gasification solid waste treatment system also includes a striking assembly 5, which is movably arranged on the furnace body 1, and the rotating furnace body 1 in the working state drives the striking assembly ...

Embodiment 2

[0042] As a further improvement of the above-mentioned embodiment, in this embodiment, during the cycle of one rotation of the furnace body 1, the beating assembly 5 passes the highest point at least once at a certain moment, and the above-mentioned highest point is the distance from the end of the beating assembly 5 The vertical distance of the furnace body is the farthest. In this embodiment, by setting the highest point, the falling height is high, and the gravity is large when knocking, which increases the removal of ash or waste residue in the furnace body 1; at the same time, after passing the highest point, it continues to rotate, and the striking assembly 5 falls by gravity. Hit the furnace body 1.

[0043] In the present embodiment, two striking assemblies 5 are arranged symmetrically, on the outer periphery of the furnace body 1 , two strikings can be realized each time. Certainly, there may be more striking assemblies 5 , which may be evenly distributed on the oute...

Embodiment 3

[0047] As a further improvement of the above embodiment, in this embodiment, the striking assembly 5 includes a striking hammer 6, a connecting rod 7 connected to the striking hammer 6, and a through hole 8 is provided at the end of the connecting rod 7; in this embodiment , a fixing seat 9 is provided on the outer surface of the furnace body 1, a connecting hole 15 matching the through hole 8 is arranged on the fixing seat 9, and a fastener (for example, the fastener can be configured as a bolt assembly, a rivet, etc.) Through the through hole 8 and the connecting hole 15, the striking assembly 5 and the fixing seat 9 can be rotatably assembled. Compared with Embodiment 1 and / or Embodiment 2, in this embodiment, the beating assembly 5 is movably connected to the fixed seat 9 through fasteners, etc., and the beating assembly 5 is loosely connected to the furnace body 1 , falling causes safety problems.

[0048] Further, refer to Figure 8 As shown, the connecting rod 7 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com