Metal-air battery cathode and preparation method thereof

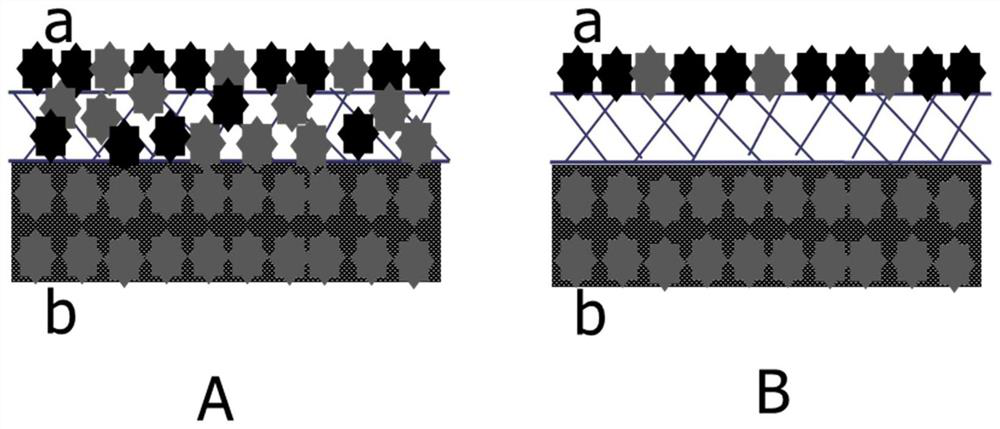

A metal-air battery and air cathode technology, which is applied to battery electrodes, fuel cell half-cells, primary battery-type half-cells, circuits, etc., can solve the problems of easy corrosion of nickel foam, leakage of electrolyte, and increased service life And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of current-collecting layer: 30% PTFE emulsion 5.3g of water-repellent agent is mixed with acetylene black 0.4g, and then 2ml of ethanol is added and stirred evenly to obtain carbon powder / hydrophobic agent mixed paste, and the paste is scraped into nickel foam to obtain Collector layer, dry the collector layer at 25°C, and bake at 340°C for 1h; the filling amount of the carbon powder / hydrophobic agent mixed paste in the metal foam is 0.2mg / mm 3 ; The mass ratio of carbon powder and hydrophobic agent in the mixed paste is 1:4, first mixing the hydrophobic agent with carbon powder is to make the hydrophobic agent disperse more evenly, and to prevent the hydrophobic agent from agglomerating after directly adding the solvent .

[0038](2) Preparation of the catalytic layer: roll-press 60% PTFE emulsion 50g of hydrophobic agent and 180g slurry of Ag-MnOx / C catalyst into a catalytic layer by rolling method; and bake the catalytic layer at 350°C for 24h, The ...

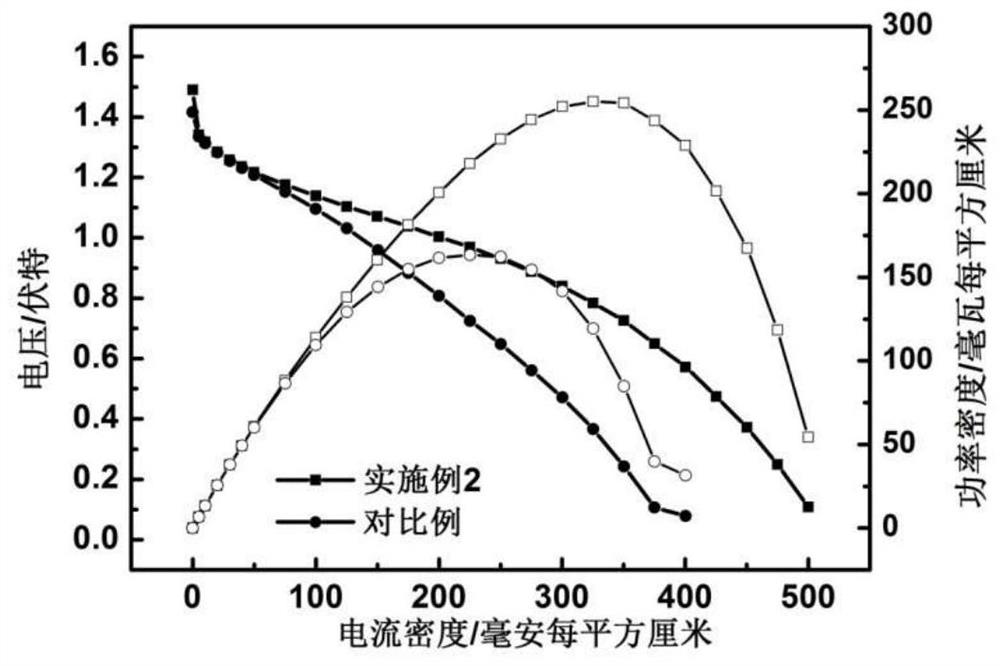

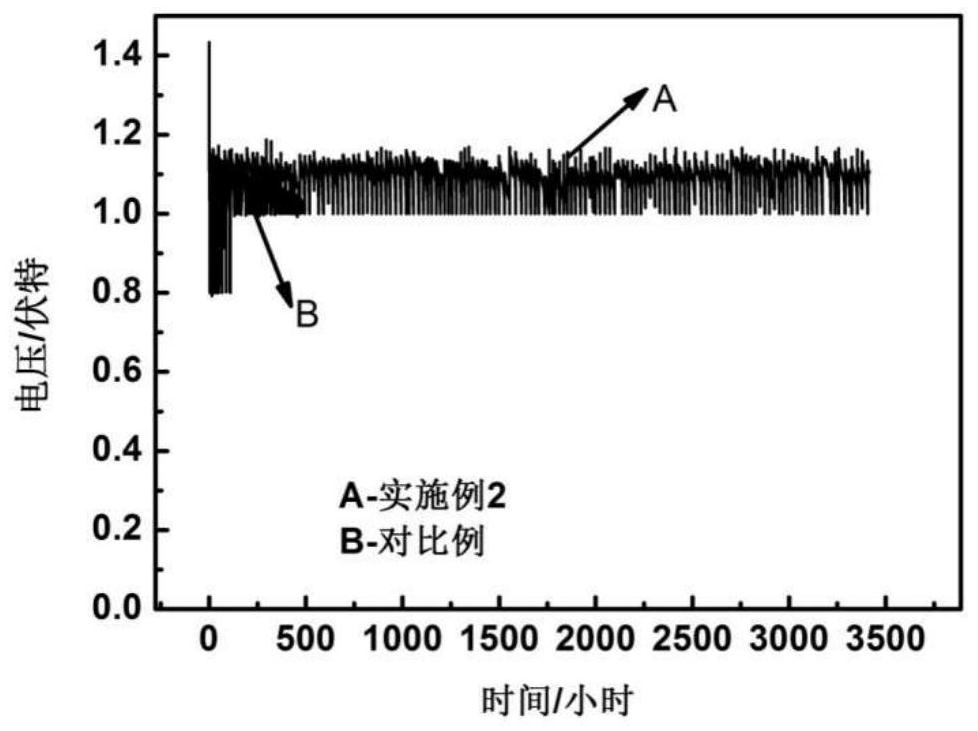

Embodiment 2

[0042] (1) Preparation of current-collecting layer: Mix 4.0 g of hydrophobic agent 30% PTFE emulsion with 0.8 g of acetylene black, add 2 mL of ethanol solvent, stir evenly to obtain a carbon powder / hydrophobic agent mixed paste, scrape or squeeze the paste To obtain a collector layer in nickel foam, dry the collector layer at 25°C and bake at 340°C for 1h, the filling amount of the carbon powder / hydrophobic agent mixed paste in the metal foam is 0.5mg / mm 3 The mass ratio of the carbon powder and the hydrophobic agent in the mixed paste is 2:3; the hydrophobic agent is mixed with the carbon powder first in order to make the hydrophobic agent disperse more evenly, and to prevent the hydrophobic agent from agglomerating after directly adding the solvent .

[0043] (2) Preparation of the catalytic layer: roll-press 60% PTFE emulsion 250g of hydrophobic agent and 180g slurry of Ag-MnOx / C catalyst into catalytic layer by rolling method; and bake catalytic layer at 350°C for 24h, an...

Embodiment 3

[0048] (1) Preparation of current collecting layer: Add 2.3g of hydrophobic agent 30% PTFE emulsion and 1.3g of acetylene black into 2ml of ethanol solvent, stir evenly to obtain a mixed paste of carbon powder / hydrophobic agent, scrape or squeeze the paste until foam The collector layer was obtained in nickel, the collector layer was dried at 80°C for 1h, and fired at 340°C for 1h, and the filling amount of the carbon powder / hydrophobic agent mixed paste in the metal foam was 1.0mg / mm 3 The mass ratio of the carbon powder and the hydrophobic agent in the mixed paste is 1:2; the hydrophobic agent is first mixed with the carbon powder in order to make the hydrophobic agent disperse more evenly, and at the same time prevent the hydrophobic agent from agglomerating after directly adding the solvent .

[0049] (2) Preparation of catalytic layer: adopt roll pressing method to roll 1250g of 60% PTFE emulsion and Ag-MnOx catalyst 180g into catalytic layer; 0.5mg / mm 2 ;

[0050] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com