Cobalt-sulfur compound/nitrogen-sulfur-doped carbon composite catalyst and preparation method thereof

A cobalt-sulfur compound and carbon composite technology, applied in the field of electrocatalysis, can solve the problems of unsatisfactory catalytic performance of catalysts, hindering large-scale commercial production, uneven distribution of catalysts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

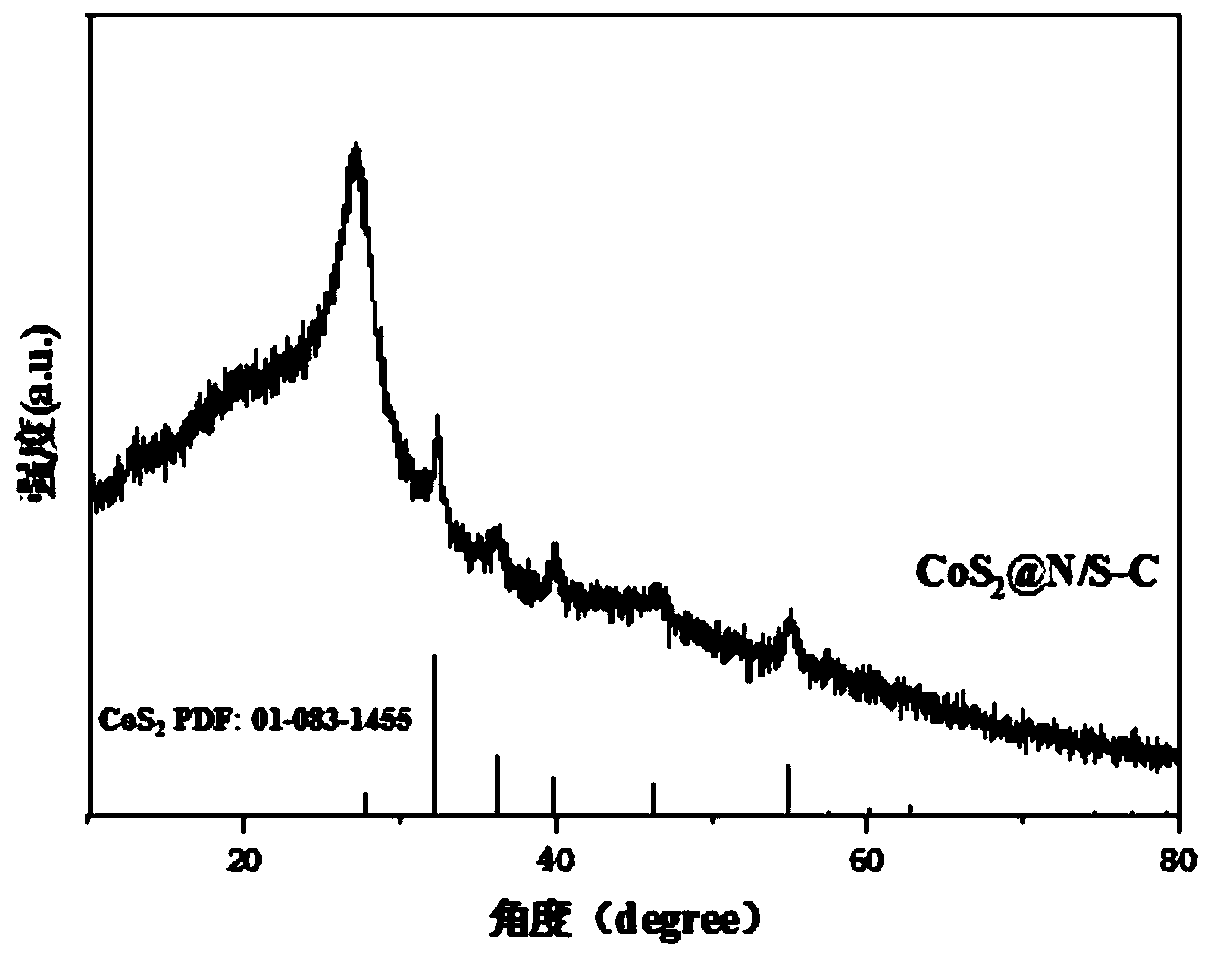

Embodiment 1

[0035] A kind of cobalt sulfur compound / nitrogen-sulfur doped carbon composite catalytic material, its preparation method comprises the steps:

[0036] 1) Weigh 0.001mol cobalt nitrate, 0.004mol thiourea and 0.5g polyaniline, mix and ball mill for 2h at 180rmp to obtain mixed raw materials;

[0037] 2) Transfer the mixed raw materials obtained in step 1) into a crucible, and under an Ar atmosphere, first heat to 200°C for 4 hours, then heat up to 500°C for 2 hours, and cool to room temperature with the furnace, then use deionized water and anhydrous The ethanol was washed 3 times each (the washing process was all realized by centrifuging at 8000rpm for 3min), and the washing obtained was put into a vacuum drying oven and dried at 80°C for 12h to obtain the cobalt-sulfur compound / nitrogen-sulfur compound Heterocarbon composite catalytic material (cobalt disulfide / nitrogen sulfur doped carbon composite electrocatalytic material).

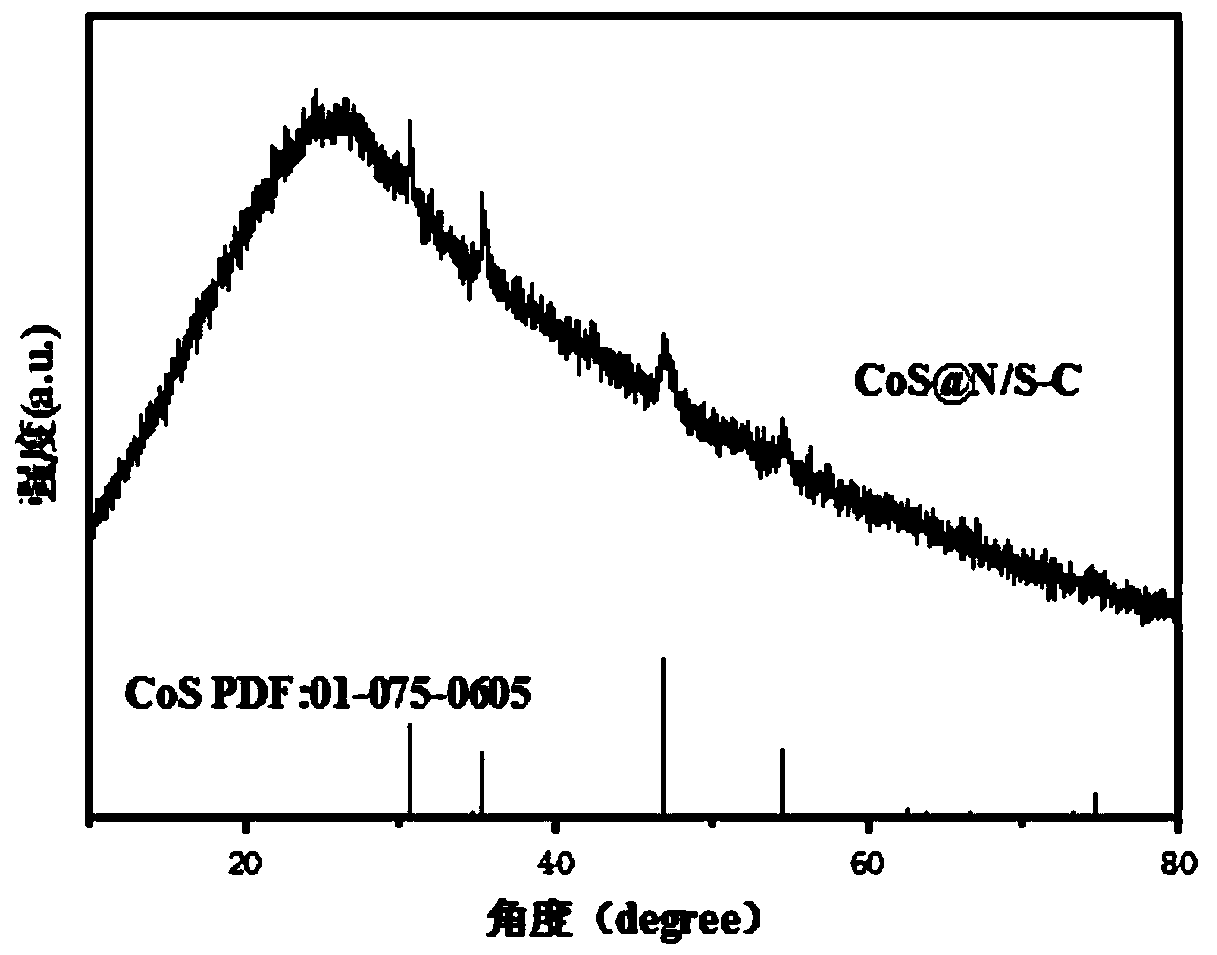

Embodiment 2

[0039] A kind of cobalt sulfur compound / nitrogen-sulfur doped carbon composite catalytic material, its preparation method comprises the steps:

[0040] 1) Weigh 0.001mol cobalt nitrate, 0.004mol thiourea and 0.5g polyaniline, mix and ball mill for 2h at 180rmp to obtain mixed raw materials;

[0041]2) Transfer the mixed raw materials obtained in step 1) into a crucible, and in an Ar atmosphere, first heat to 200°C for 4 hours, then heat up to 600°C for 2 hours, and cool to room temperature with the furnace, then use deionized water and anhydrous The ethanol was washed 3 times each (the washing process was all realized by centrifuging at 8000rpm for 3min), and the washing obtained was put into a vacuum drying oven and dried at 80°C for 12h to obtain the cobalt-sulfur compound / nitrogen-sulfur compound Heterocarbon composite catalytic material (cobalt sulfide / nitrogen sulfur doped carbon composite electrocatalytic material).

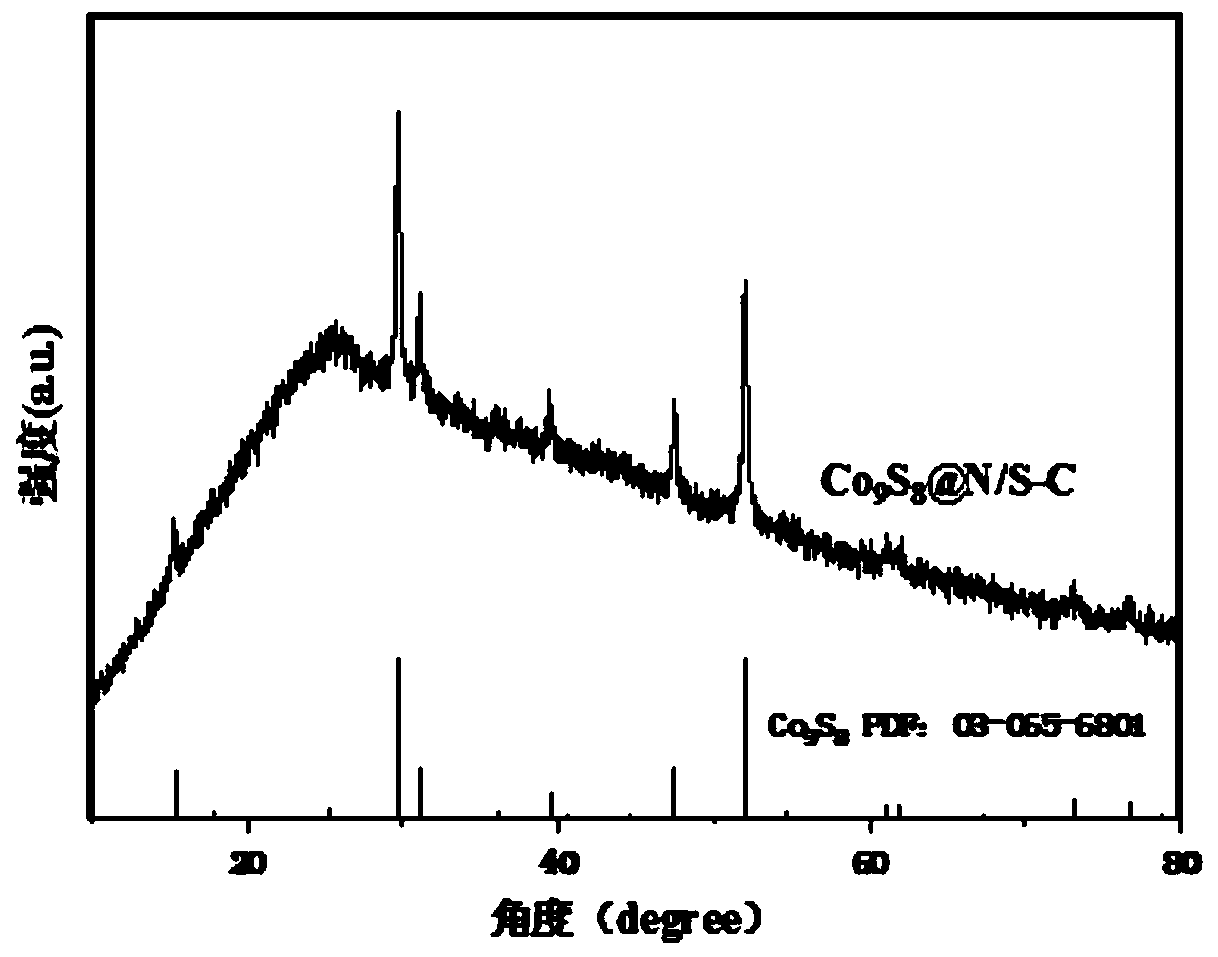

Embodiment 3

[0043] A kind of cobalt sulfur compound / nitrogen-sulfur doped carbon composite catalytic material, its preparation method comprises the steps:

[0044] 1) Weigh 0.001mol cobalt nitrate, 0.012mol thiourea and 1.5g polyaniline, mix and ball mill for 2h at 180rmp to obtain mixed raw materials;

[0045] 2) Transfer the mixed raw materials obtained in step 1) into a crucible, and under an Ar atmosphere, first heat to 180°C for 6 hours, then heat up to 900°C for 4 hours, and cool to room temperature with the furnace, then use deionized water and anhydrous The ethanol was washed twice each (the washing process was all realized by centrifuging at 8000rpm for 3min), and the washing obtained was put into a vacuum drying oven and dried at 80°C for 6h to obtain the cobalt-sulfur compound / nitrogen-sulfur compound Heterocarbon composite catalytic material (nine cobalt octasulfide / nitrogen-sulfur doped carbon composite electrocatalytic material).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com