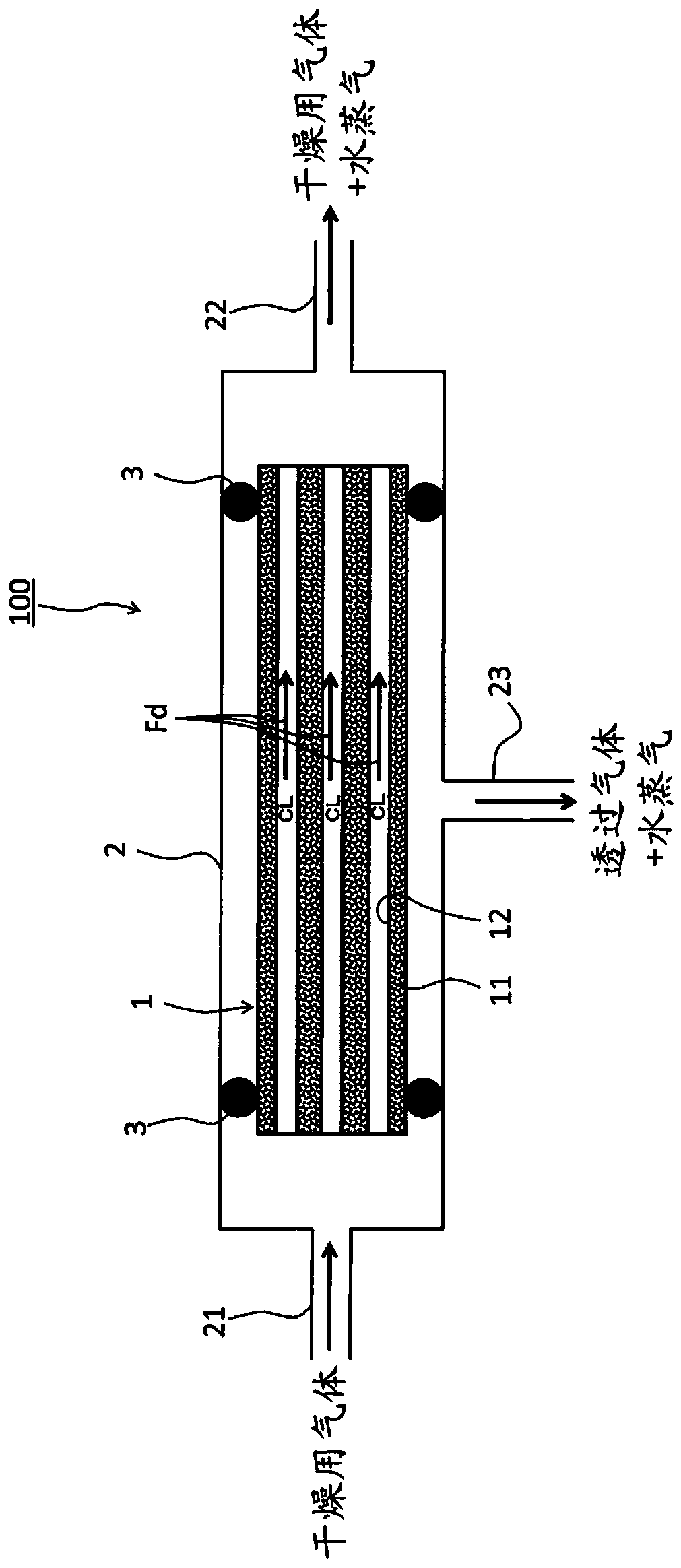

Method for drying separation membrane and method for producing separation membrane structure

A drying method and separation membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve problems such as clogging of pores, and achieve the effect of simple and rapid drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

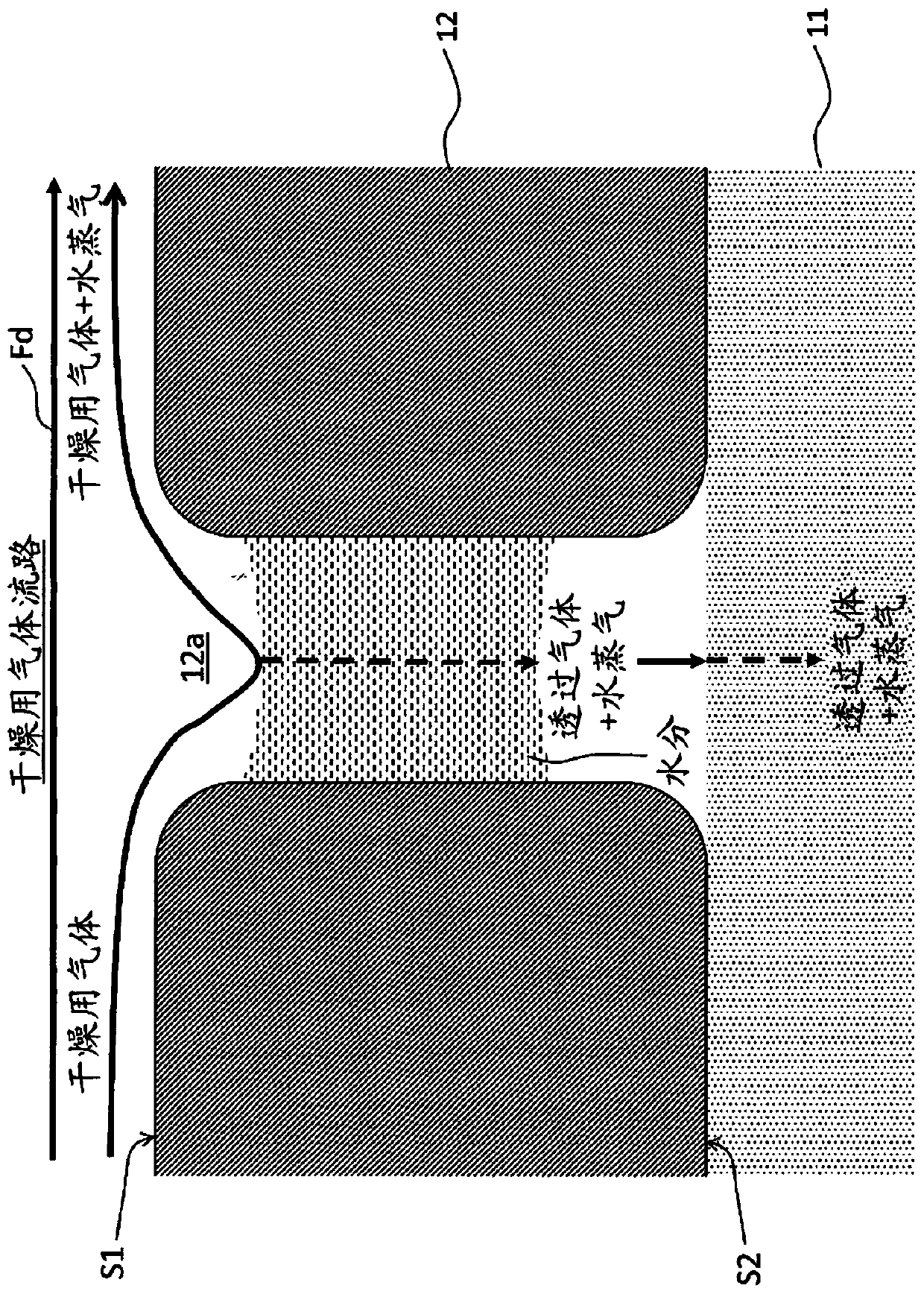

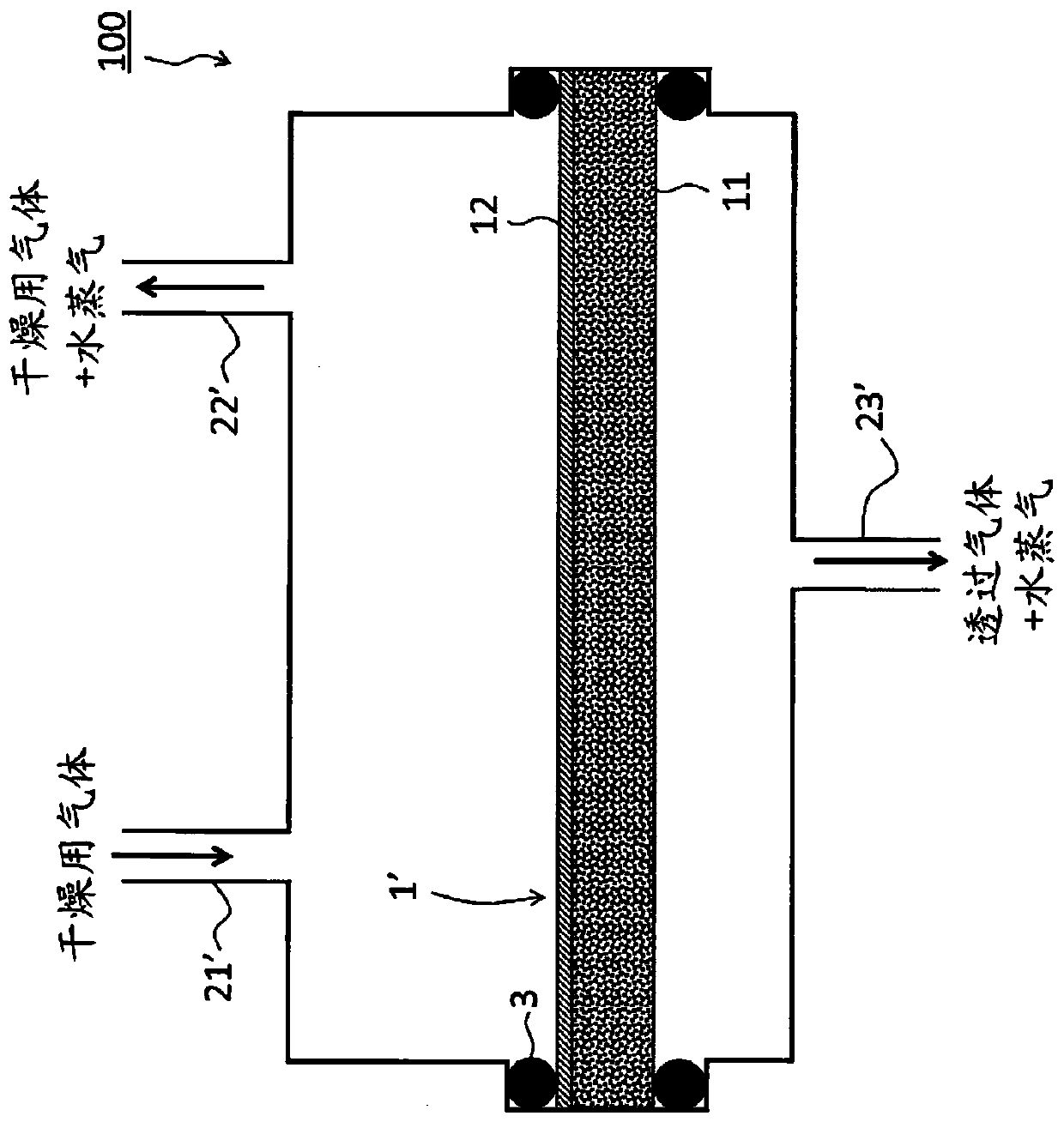

Method used

Image

Examples

Embodiment

[0077] (Sample No.1~5)

[0078] First, add 30% by volume of an inorganic binder to 70% by volume of alumina particles (aggregate) with an average particle diameter of 12 μm, and then add a molding aid such as an organic binder and a pore-forming agent, and perform dry mixing Thereafter, water and a surfactant were added, mixed and kneaded, thereby preparing kneaded clay. As an inorganic binder, talc, kaolin, feldspar, clay, etc. with an average particle size of 1 to 5 μm are used to make SiO 2 (70% by mass), Al 2 o 3 (16% by mass), an alkaline earth metal and an alkali metal (11% by mass).

[0079] Next, the kneaded clay is extruded to produce a molded body of the monolithic porous base material. Then, the molded body of the porous substrate was fired (1250°C, 1 hour) to obtain an alumina matrix having a plurality of cells.

[0080] Next, PVA (organic binder) was added to the alumina powder to prepare a slurry, which was used to form a molded body of an intermediate layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com