Avalanche photodiode

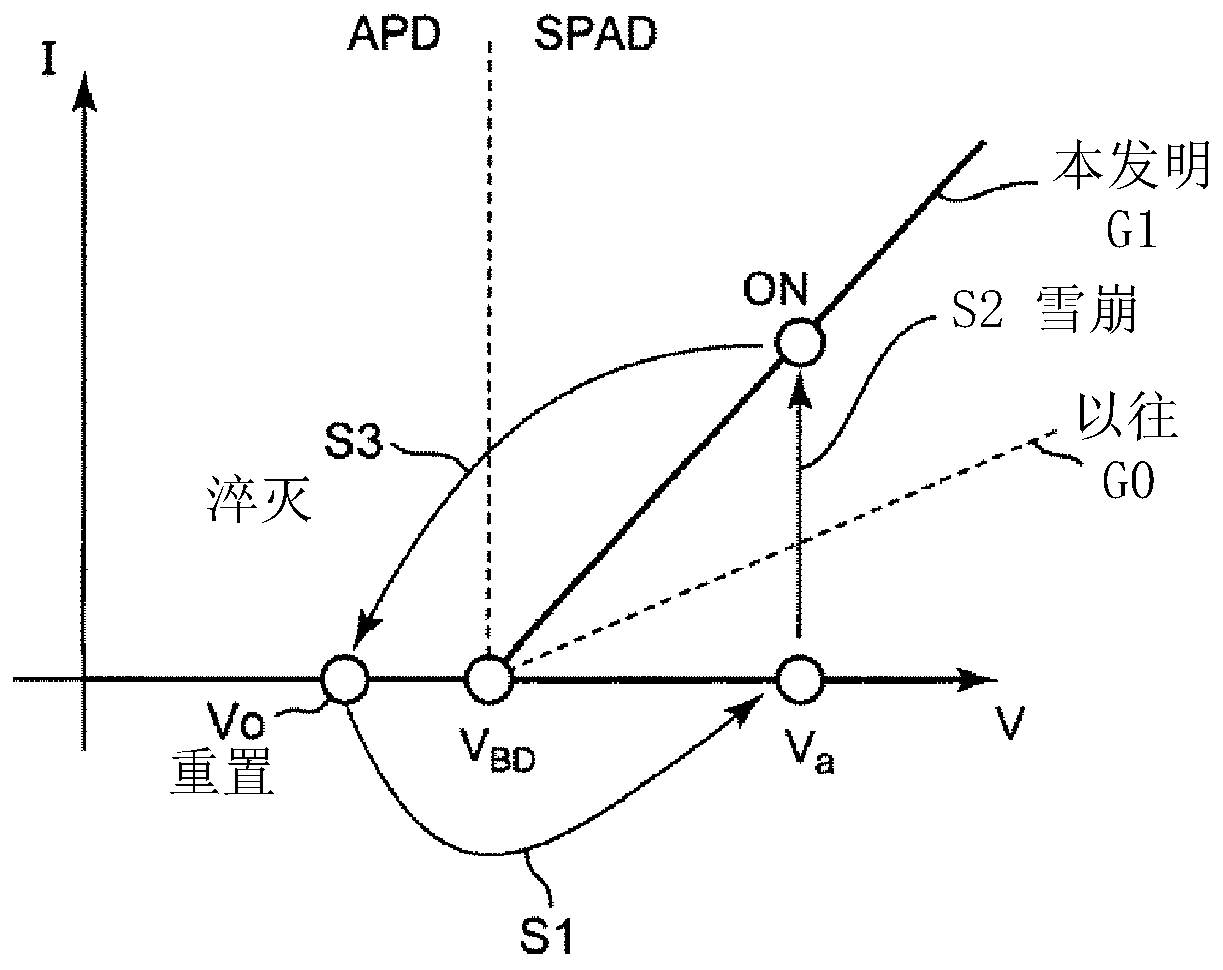

An avalanche photoelectric and diode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as malfunctioning components, and achieve the effects of increasing the maximum amplified current, improving light sensitivity, and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

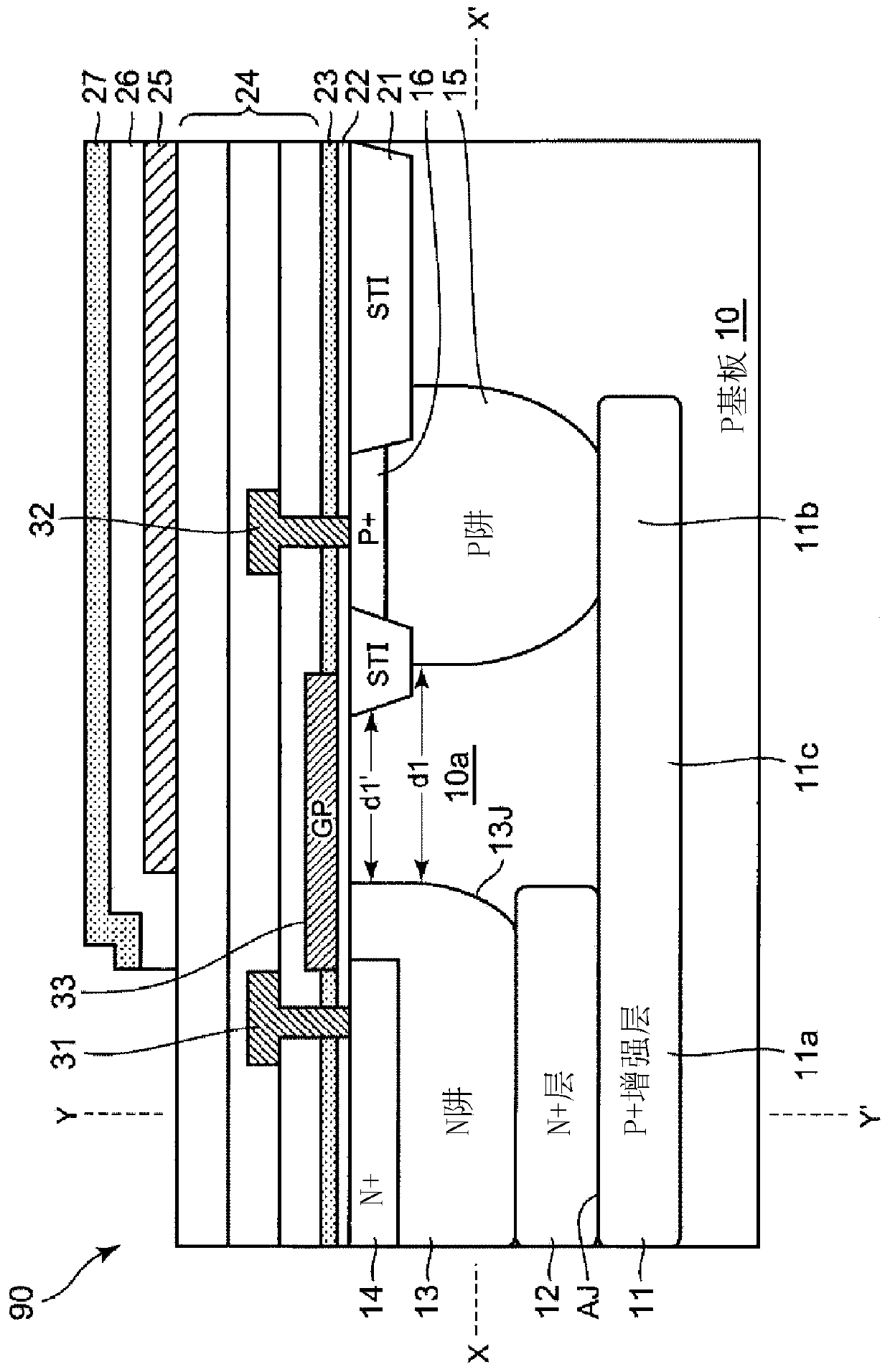

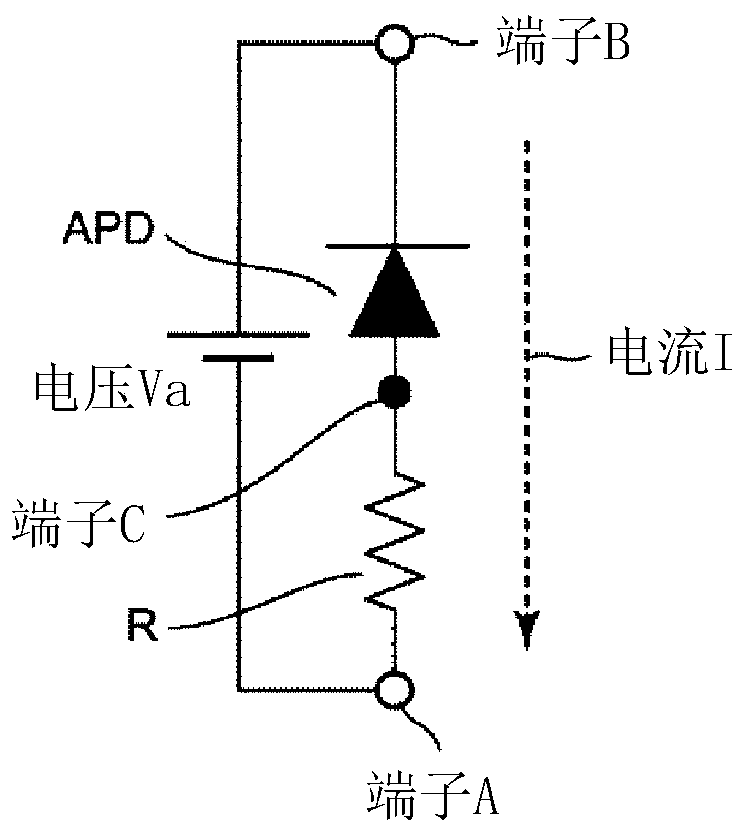

[0049] (Avalanche photodiode configuration)

[0050] figure 1 A cross-sectional structure of an avalanche photodiode (SPAD) 90 according to the first embodiment of the present invention is shown. This SPAD 90 includes a P substrate (silicon substrate) 10 having a uniform impurity concentration (resistivity of about 10Ω·cm) as a substrate semiconductor layer. It includes: P+ enhancement layer (impurity concentration 1×10 17 cm -3 left and right) 11, as the first semiconductor layer, formed in the interior of the P substrate 10 (about 2 μm in depth) to occupy a predetermined area in the lateral direction; N+ layer (impurity concentration 2×10 17 cm -3 About), which is used as the second semiconductor layer, which is formed on the P+ enhancement layer in contact with it; N well (about 2 μm in depth, impurity concentration of 3×10 16 cm -3 Left and right) 13, which is used as the third semiconductor layer, formed in contact with the N+ layer 12, and has a lower impurity con...

no. 2 approach

[0074] Figure 6 A cross-sectional structure of an avalanche photodiode (SPAD) 90A according to the second embodiment of the present invention is shown. In addition, in Figure 6 For and figure 1Components in the same components are denoted with the same reference numerals, and repeated descriptions are omitted.

[0075] The SPAD90A, with respect to figure 1 The SPAD 90 differs in that the first portion 11a of the P+ enhancement layer 11A that exists directly below the N+ layer 12 and the second portion 11b that exists directly below the P well 15 are only separated from each other by a distance d2( 2μm or so). Other components of the SPAD90A are with figure 1 The configuration of the SPAD90 is the same.

[0076] In the case of manufacturing this SPAD90A, the implantation mask used in the process of forming the P+ enhancement layer 11A by ion implantation is set to be used for forming figure 1 The implantation mask of the P+ enhancement layer 11 of the SPAD 90 is ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com