Process and device for lime calcining by cement kiln tail

A technology for calcining lime and cement kiln, which is applied in the field of lime calcining, which can solve the problems of high power consumption for grinding and poor grindability of massive lime, and achieve long equipment life, small footprint of equipment and utilization of vertical space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

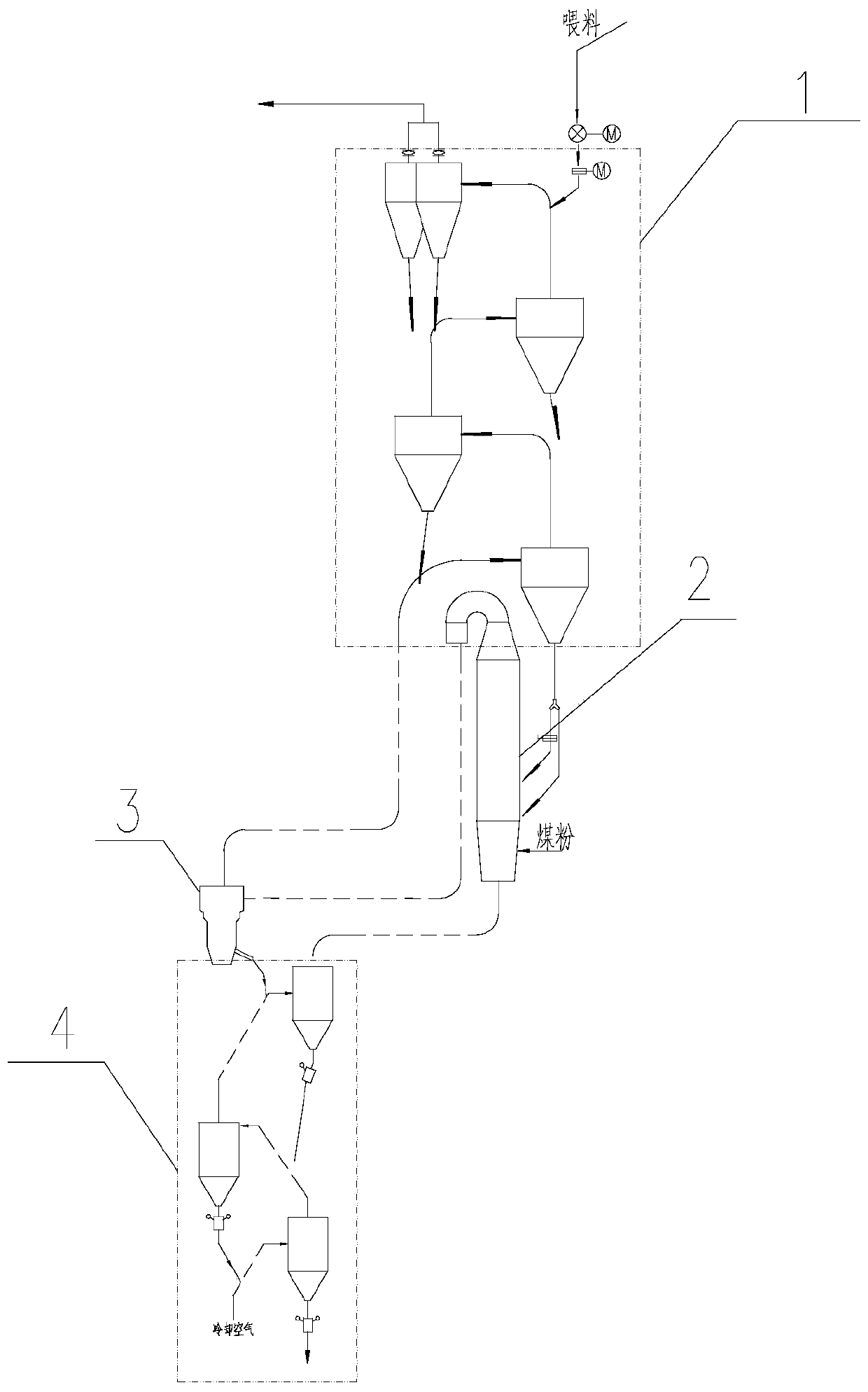

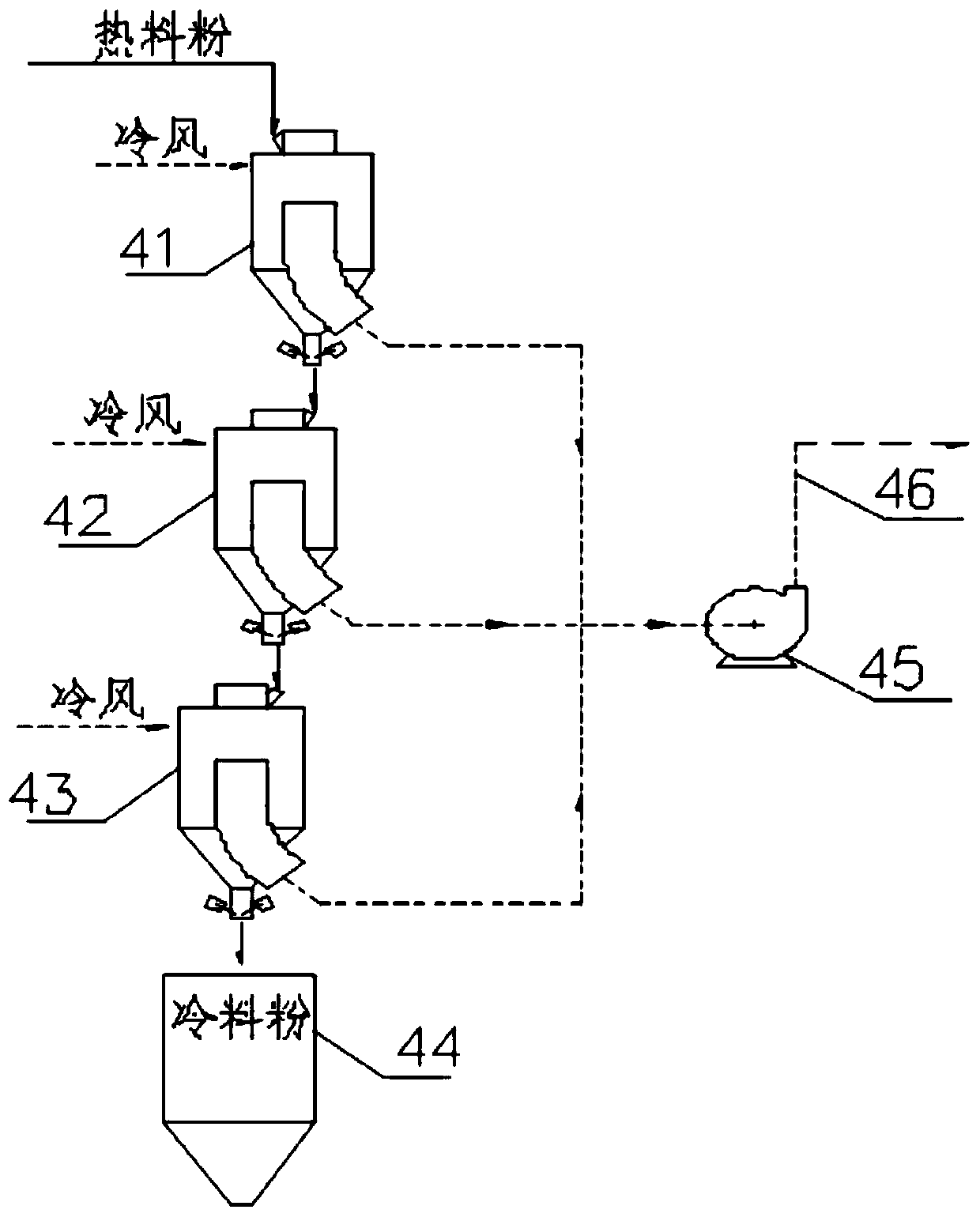

[0034] refer to figure 1 , Embodiment 1 of the present invention provides a kind of device that utilizes cement kiln tail calcined lime, comprises the preheating unit 1 of cement kiln tail, also comprises calciner 2, cyclone separator 3, cooling unit 4, and described preheating unit 1 consists of It consists of interconnected multi-stage preheating cyclones (from top to bottom are the first stage, the second stage, ..., the penultimate stage, the penultimate stage cyclone), and the penultimate stage of this preheating unit 1 The first-stage cyclone is replaced by the cyclone separator 3 (if the original cement kiln tail no longer produces cement, the last-stage cyclone of the preheating unit 1 of the preheating unit is no longer used, and the last stage of the preheating unit 1 of the original cement kiln tail can be replaced. The cylinder is directly transformed into a cyclone separator with a bottom material retention area, and the cooling unit 4 is arranged and designed acc...

Embodiment 2

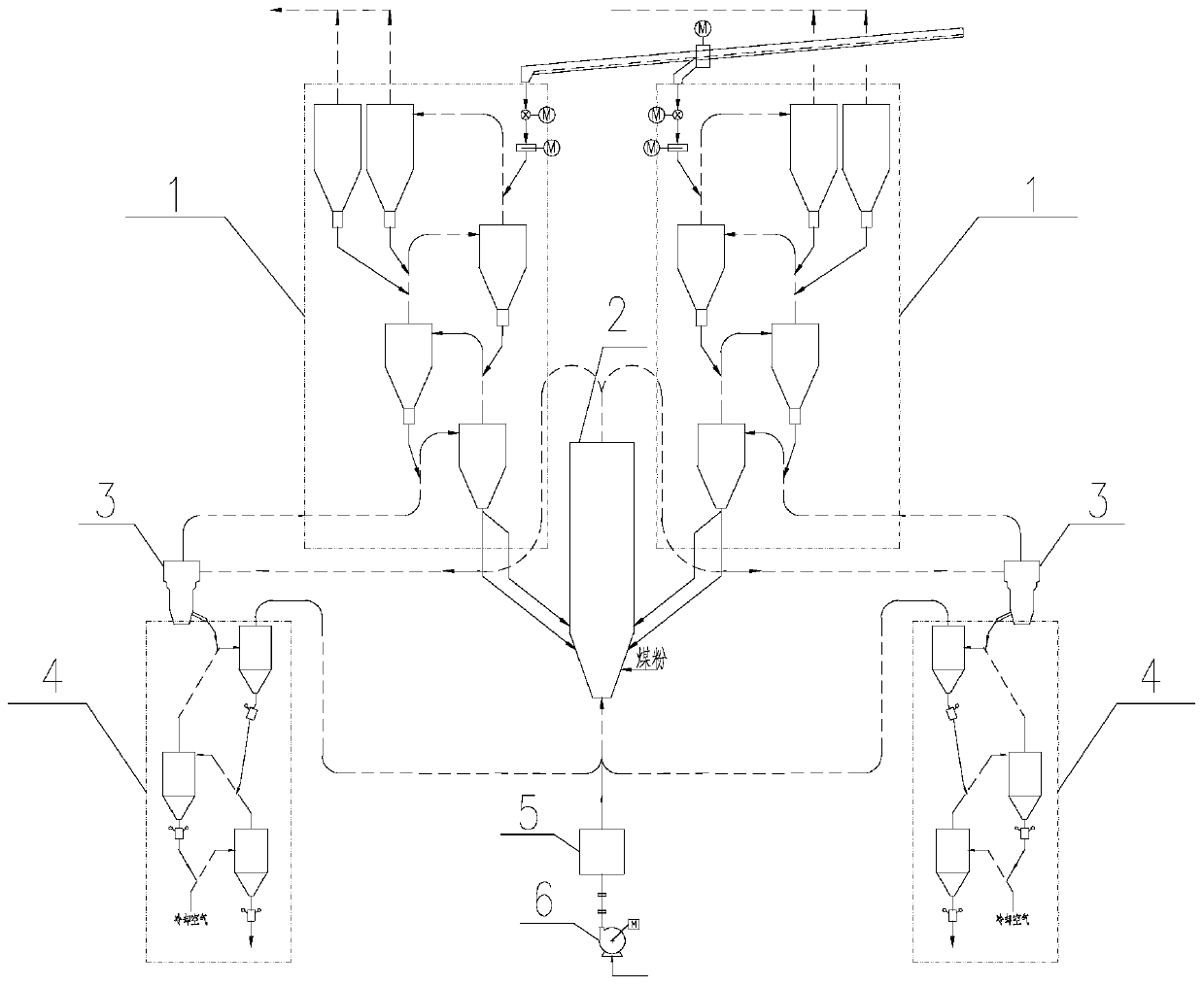

[0039] refer to figure 2 , Embodiment 2 of the present invention provides a kind of device that utilizes cement kiln tail calcined lime, comprises the preheating unit 1 of cement kiln tail, also comprises calciner 2, cyclone separator 3, cooling unit 4, and described preheating unit 1 consists of It consists of interconnected multi-stage preheating cyclones (from top to bottom are the first stage, the second stage, ..., the penultimate stage, the penultimate stage cyclone), and the penultimate stage of this preheating unit 1 The first-stage cyclone is replaced by the cyclone separator 3 (if the original cement kiln tail no longer produces cement, the last-stage cyclone of the preheating unit 1 of the preheating unit is no longer used, and the last stage of the preheating unit 1 of the original cement kiln tail can be replaced. The cylinder is directly transformed into a cyclone separator with a bottom material retention area, and the cooling unit 4 is arranged and designed ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com