A kind of leveling agent for color photoresist

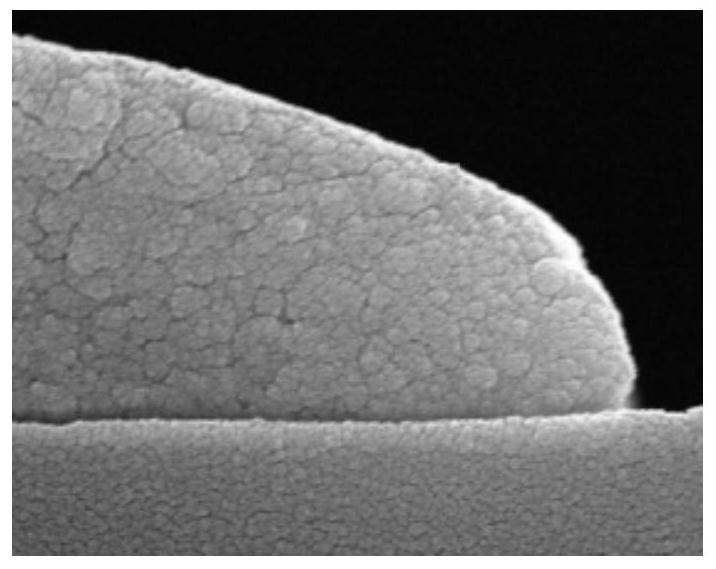

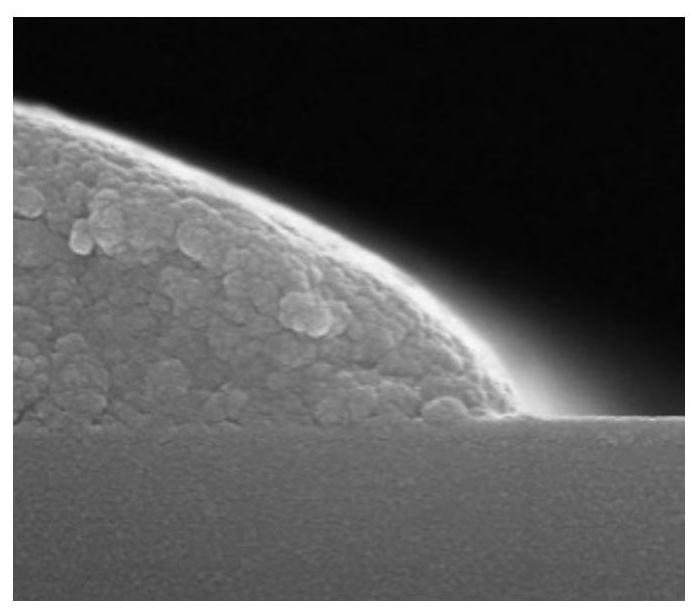

A technology of leveling agent and monomer, applied in the field of liquid crystal display, can solve the problems of flushing out the leveling agent, poor wetting of the substrate by the molten photoresist material, etc., so as to improve the fluidity and reduce the roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also relates to the preparation method of said leveling agent, comprising a polymerization reaction step and a post-treatment step,

[0029] Polymerization reaction step: use a four-necked flask as a reaction vessel, and connect a thermometer, a condenser (condensing reflux), a nitrogen inlet for protection, and a stirring paddle respectively. When synthesizing this leveling agent, benzoyl peroxide (BPO) or azobisisobutyronitrile (AIBN) is used as the initiator, and the stirring speed is 120-180rpm, and the solution of monomer, initiator, and chain transfer agent gradually turns to xylene Add dropwise for 1 to 2 hours. After the dropwise addition, continue to carry out solution polymerization in xylene at 60-80°C for 2-4 hours. The target molecular weight of the leveling agent in this technical proposal is preferably within 8000-10000, and the migration effect of the leveling agent will be deteriorated if the molecular weight is too large; dodecan...

Synthetic example 1

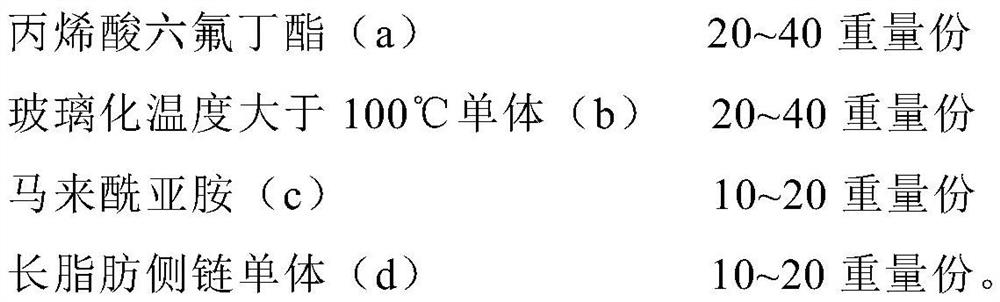

[0031] Synthesis example 1. Preparation of leveling agent A

[0032] Weigh 30 parts by weight of hexafluorobutyl acrylate, 30 parts by weight of styrene, 20 parts by weight of maleimide, 20 parts by weight of myrcene; and 6 parts by weight of initiator AIBN, 0.5 parts by weight of chain transfer agent dodecanethiol , dissolved in 100 parts by weight of xylene, mixed evenly and placed in a constant pressure funnel. In addition, 50 parts by weight of xylene was weighed and added into a four-neck flask, protected by nitrogen gas, heated to 65° C., and started to stir to 150 revolutions per minute (rpm).

[0033] Synthesis: Add the premixed monomer and initiator solution dropwise to xylene, and control the drop rate. The whole drop process takes 2 hours. After the drop is completed, keep stirring for 3 hours and add MEHQ 0.5 parts by weight to terminate the reaction.

[0034] Post-processing: use dropwise addition, after cooling the xylene solution obtained from the reaction to ...

Synthetic example 2

[0036] Synthesis example 2. Preparation of leveling agent B

[0037] Use 40 parts by weight of hexafluorobutyl acrylate, 30 parts by weight of acrylonitrile, 15 parts by weight of maleimide, 15 parts by weight of undecene; and 7 parts by weight of initiator AIBN, 0.5 parts by weight of chain transfer agent dodecanethiol , dissolved in 100 parts by weight of xylene, mixed evenly and placed in a constant pressure funnel. In addition, 50 parts by weight of xylene was weighed and added into a four-neck flask, protected by nitrogen gas, the temperature was raised to 60° C., and the stirring was started to 150 rpm.

[0038] Synthesis: Add the premixed monomer and initiator solution dropwise to xylene, and control the drop rate. The whole drop process takes 1.5 hours. After the drop is completed, keep the temperature and continue to stir for 4 hours. Add 0.5 parts by weight of MEHQ terminated the reaction.

[0039] Post-processing: use dropwise addition, after cooling the xylene so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com