Mechanical equipment operating state monitoring method and system used for edge calculation side

A technology of mechanical equipment and edge computing, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of trend change analysis, can not reflect the details of equipment operating status changes, etc., to achieve the effect of improving the level of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

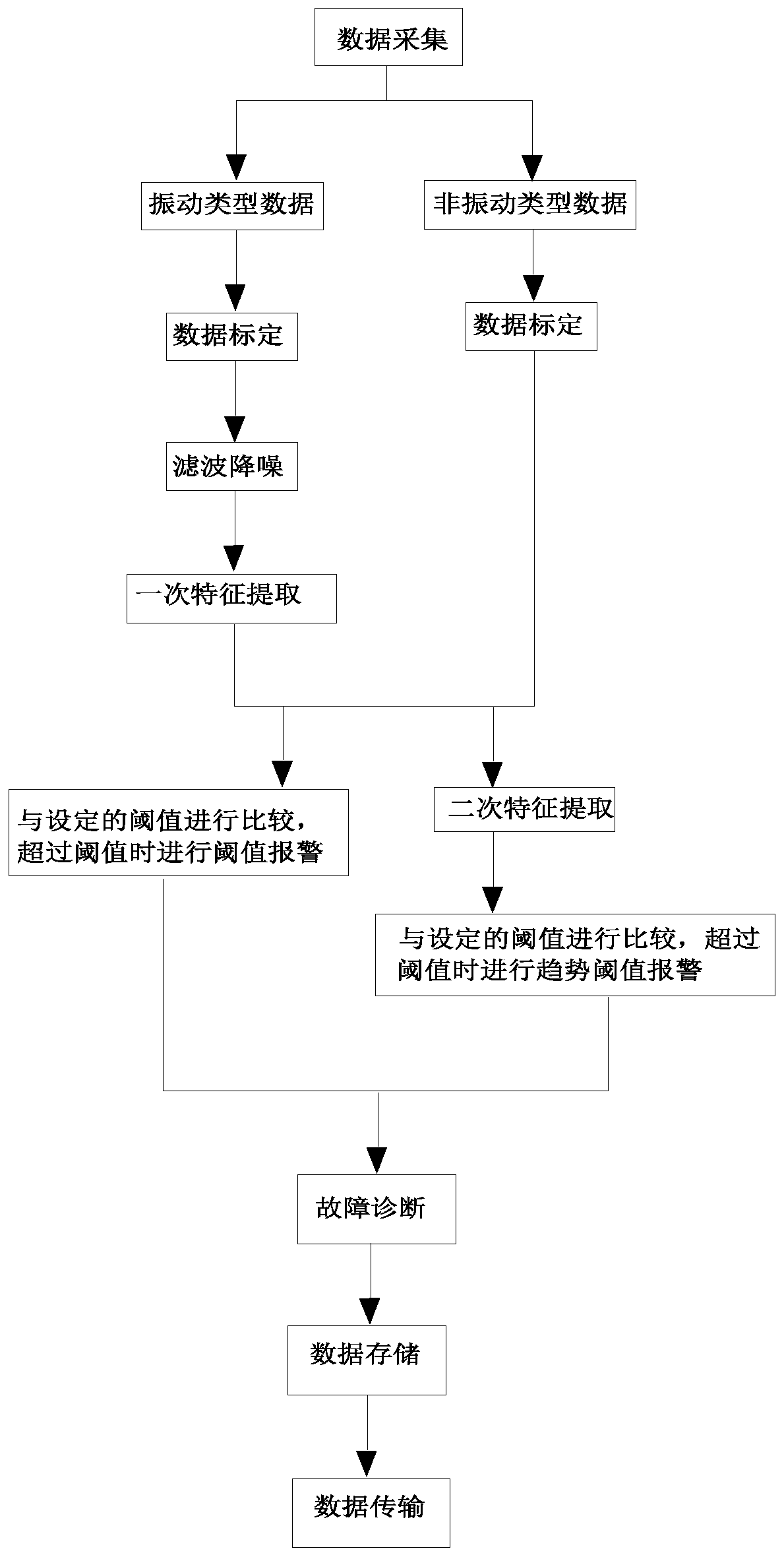

[0048] A method for monitoring the operating status of mechanical equipment on the edge computing side, such as figure 1 As shown, the method includes the following steps:

[0049] (1) Design the sensor layout plan, select the required type of sensors, arrange the sensors for the mechanical equipment according to the plan, and record the corresponding information in the configuration file; use various types of sensors (including temperature sensors and acceleration sensors, etc.) to collect the operating condition data of the mechanical equipment Including vibration type data and non-vibration type data; wherein, the eigenvalues corresponding to vibration type data include effective value, peak value, rotational frequency and its multiplier, bearing characteristic frequency and blade passing frequency; non-vibration type data include rotational speed and temperature;

[0050] (2) Then, the above-mentioned working condition data signals are subjected to signal conditioning (d...

Embodiment 2

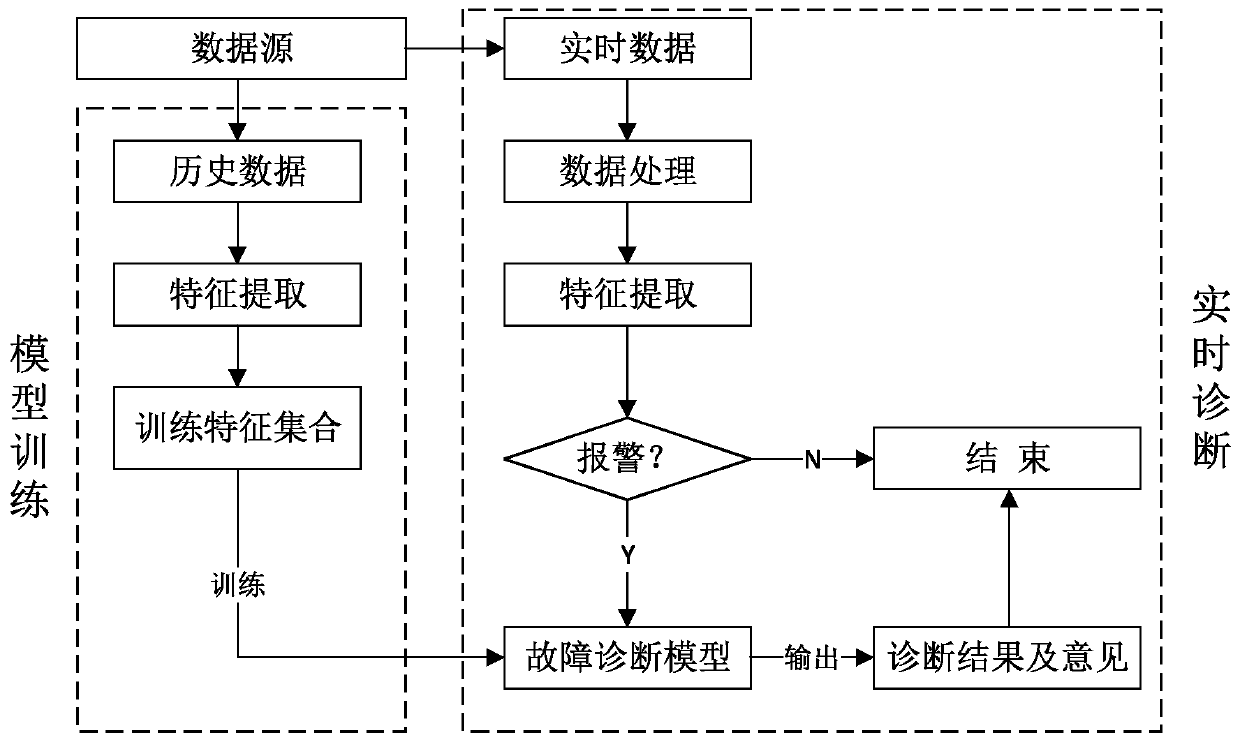

[0060] A method for fault diagnosis of mechanical equipment, such as figure 2 As shown, the method includes the following steps:

[0061] (1) Model training

[0062] a) Obtain historical operation data of mechanical equipment from the data center;

[0063] b) Perform data processing and feature extraction, and determine the training sample set in combination with the equipment operating status corresponding to each data;

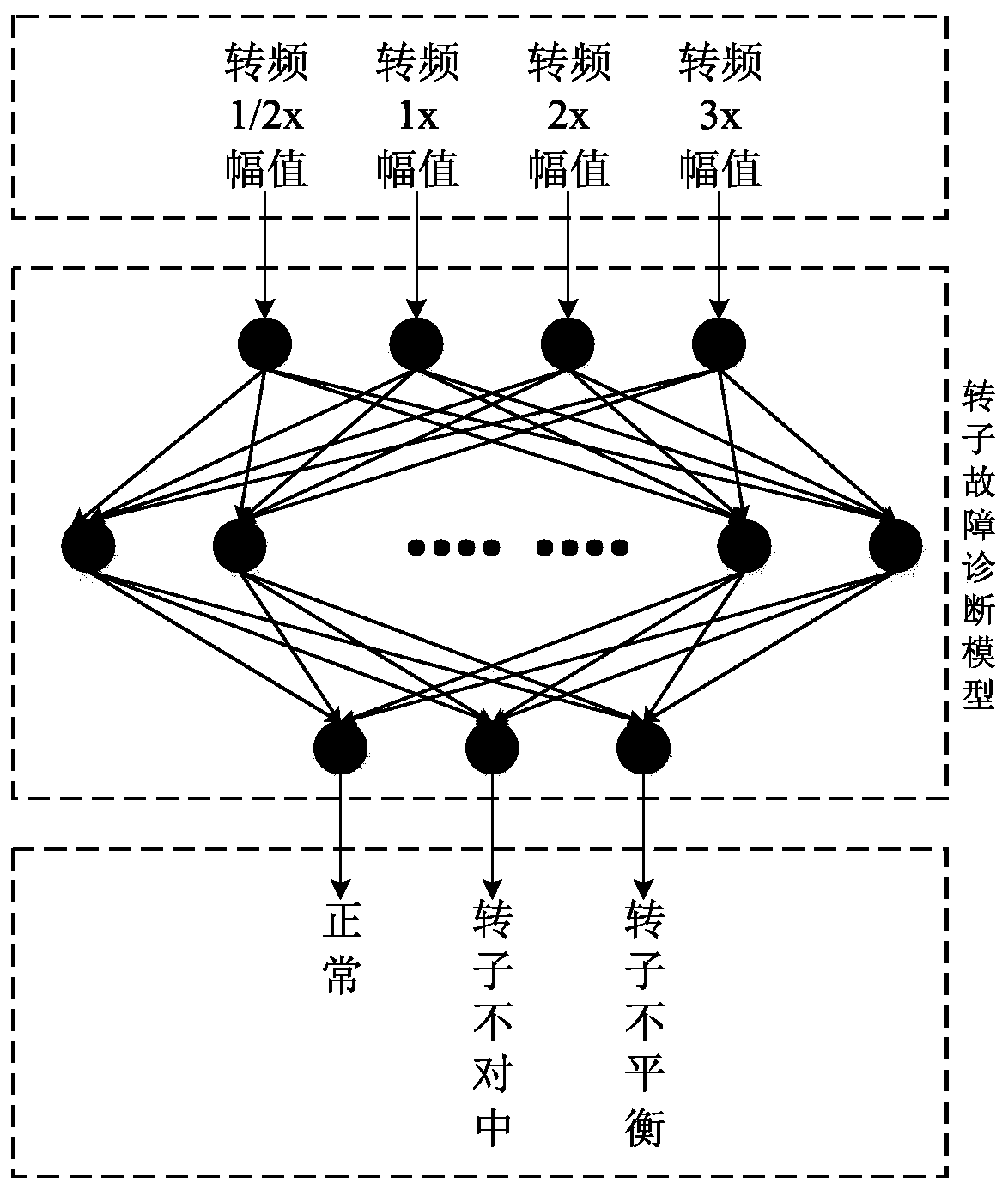

[0064] c) Determine the parameters of the BP neural network, including the number of input layer nodes, the number of hidden layer nodes, and the number of output layer nodes, train the BP neural network according to the training sample set, obtain the neural network weight matrix, and establish a fault diagnosis model;

[0065] (2) Real-time diagnosis

[0066] a) Collect real-time operation data of mechanical equipment;

[0067] b) carry out data processing and feature extraction, and use the extracted features to carry out alarm discrimination, wherei...

Embodiment 3

[0071] A method for discriminating alarms of mechanical equipment, said method comprising the following steps:

[0072] (1) For non-vibration type data, including temperature, rotational speed, etc., directly compare with the set threshold value, if the threshold value is exceeded continuously for 3 times in normal state, then set this type of physical quantity as an alarm state, for example, temperature alarm, Speed alarm, etc.; if the threshold value is not exceeded for 3 consecutive times in the alarm state, the physical quantity of this type will be released from the alarm and return to the normal state;

[0073] (2) For the vibration type data, a feature extraction is completed for the first time, and the extracted feature value is compared with the set threshold value. If it exceeds the threshold value for 3 times in a normal state, the feature value is set as an alarm state; if If the threshold value is not exceeded for 3 consecutive times in the alarm state, the char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com