Water treatment method and device

A water treatment device and water treatment technology, applied in water/sewage treatment, natural water treatment, non-polluted water treatment, etc., can solve the problems of high cost and reduced ultraviolet intensity, achieve high TOC removal rate, and improve decomposition efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

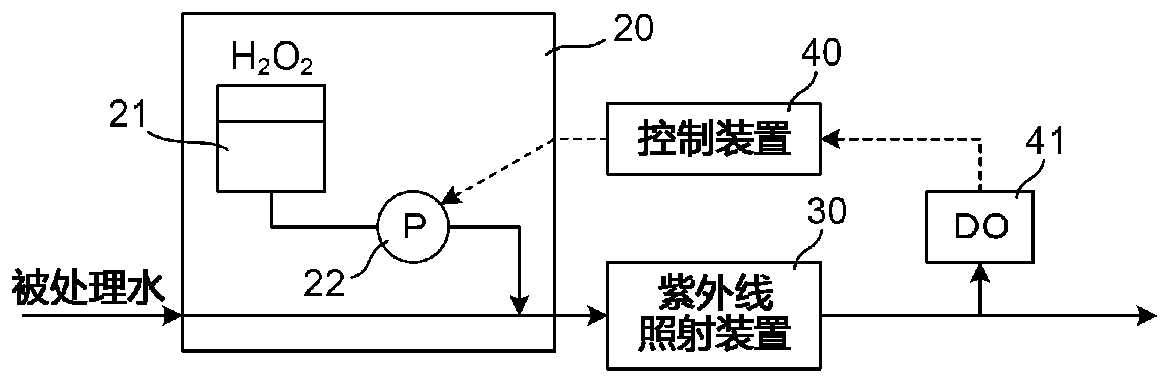

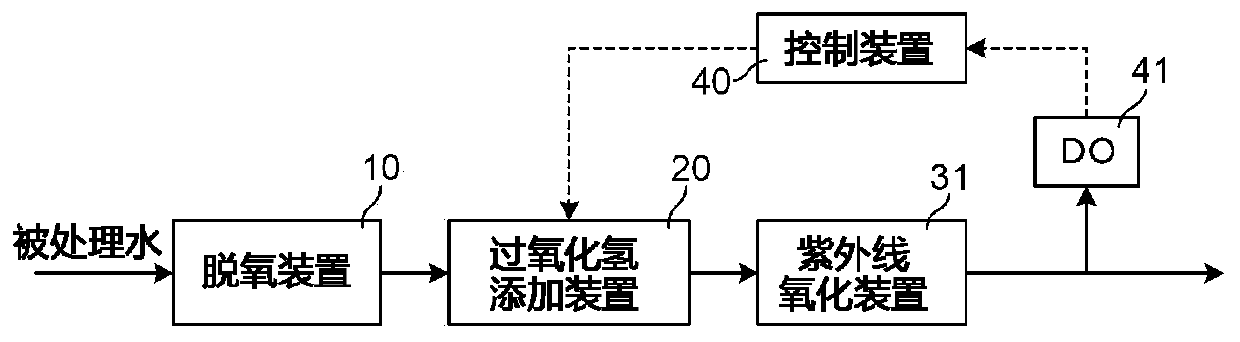

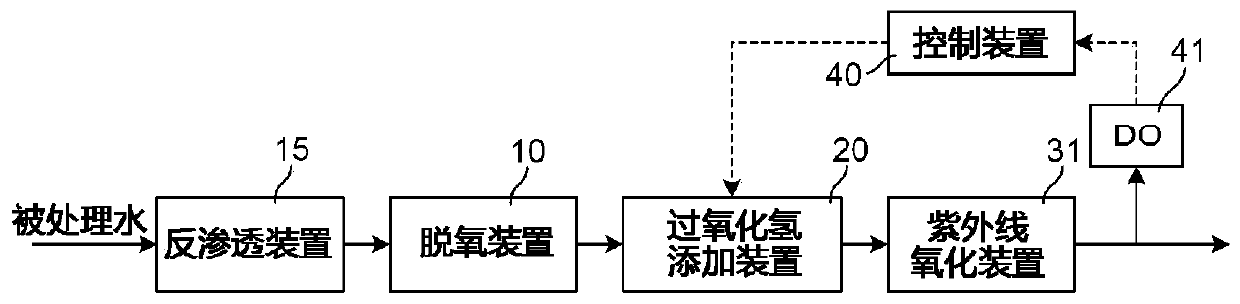

Image

Examples

experiment example 1

[0053] assembled Figure 7 The structure shown in the device. In this device, isopropanol (CH 3 CH(OH)CH 3 ;IPA), then add H 2 o 2 , with added IPA and H 2 o 2 The water is subjected to ultraviolet oxidation treatment. The water quality of the pure water used here is: the resistivity is above 1MΩ·cm, the TOC is below 3μg / L, the dissolved oxygen concentration is 7.8mg / L, and the H 2 o 2 The concentration is below 1 μg / L. This device uses pure water containing IPA as organic matter (TOC component) as water to be treated, and decomposes the organic matter contained in the water to be treated. It can be said that deoxidation treatment by membrane degassing before adding IPA is used. It is used to reduce the dissolved oxygen concentration of the treated water. Considering that degassing through the membrane generally does not remove IPA in water, the Figure 9 The device shown will be obtained by supplying the treated water containing IPA to the deoxidation treatment dev...

experiment example 2

[0065] In addition to setting the TOC concentration of the treated water, that is, the TOC concentration at the inlet of the ultraviolet oxidizing device 31 to 1000 μg / L, an addition of H 2 o 2 The experiment was performed under the same conditions as in Experimental Example 1 except that the addition amount was 20.0 mg / L. The results are shown in Table 2. It can also be obtained by reducing the concentration of dissolved oxygen in the water to be treated and adding H 2 o 2 , so that the TOC removal rate is improved.

[0066] In addition, the dissolved oxygen concentration was adjusted to 7.8 mg / L by bypassing the membrane degassing module 11, and the H 2 o 2The addition amount of was set as 0mg / L, 2.5mg / L, and the TOC removal rate was measured. These results are also shown in Table 2. Bypassing the membrane degassing module 11 means that the concentration of dissolved oxygen is kept substantially at the saturation level under atmospheric pressure without reducing the c...

experiment example 3

[0070] In addition to setting the dissolved oxygen concentration at the inlet of the ultraviolet oxidizing device 31 to 500 μg / L, H 2 o 2 The experiment was performed under the same conditions as in Experimental Example 1 except that the addition amount was 0 mg / L, 1.5 mg / L, 2.5 mg / L, and 5.0 mg / L. The results are shown in Table 3.

[0071] 【table 3】

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com