Novel asymmetric wettable electrostatic spinning double-layer film and preparation method thereof

An electrospinning and asymmetric technology, applied in bandages, absorbent pads, medical science, etc., can solve the problems of not being suitable for large-scale production and complicated preparation process, and achieve the effect of promoting rapid healing, simple process and favorable absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

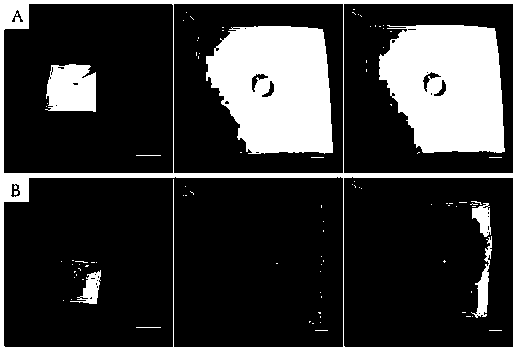

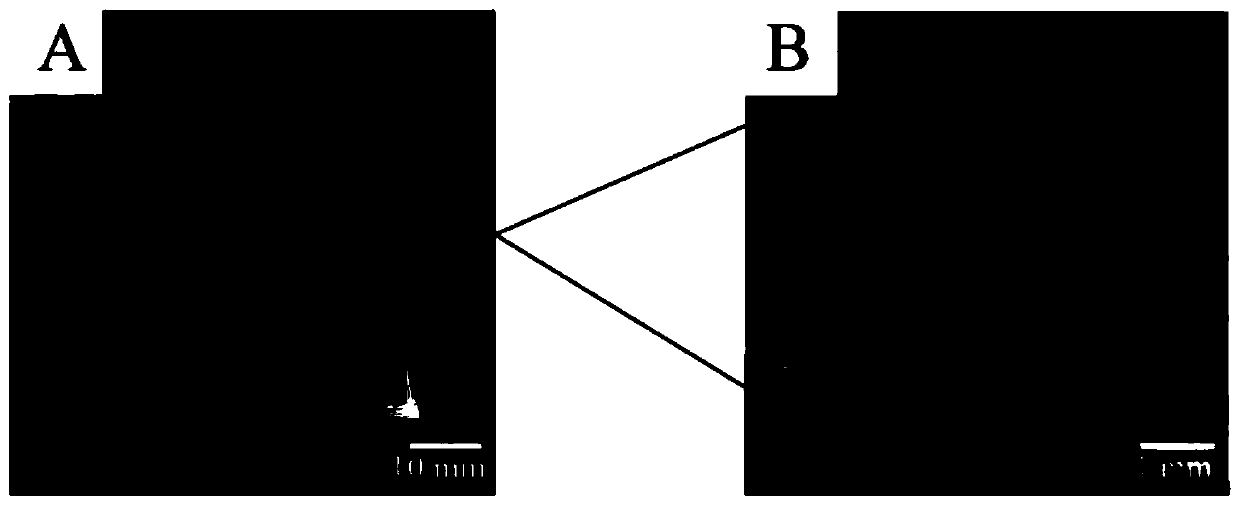

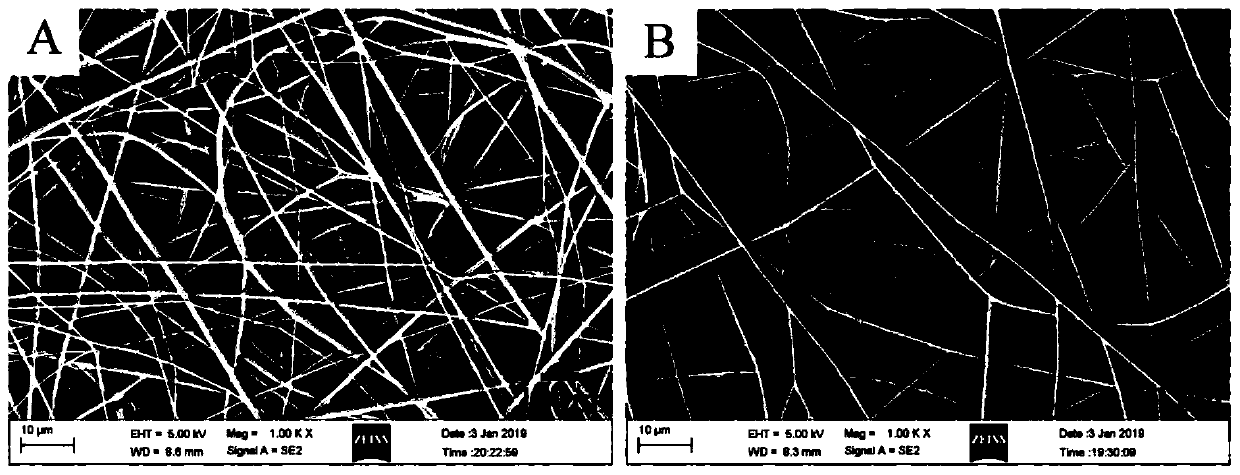

[0044] An embodiment of the novel asymmetric wettable electrospinning double-layer membrane of the present invention, the novel asymmetric wettable electrostatic spinning double-layer membrane described in this embodiment includes a hydrophobic layer and a hydrophilic layer, so The hydrophobic layer and the hydrophilic layer are bonded and connected; the hydrophobic layer is made of hydrophobic materials, and the hydrophilic layer is made of hydrophilic materials. The hydrophobic material is poly(lactic acid-glycolic acid); the hydrophilic material comprises PEG-COOH, silk fibroin and a cross-linking agent; the mass ratio of the PEG-COOH and silk fibroin is: PEG-COOH: Silk fibroin=10:3; the cross-linking agent is a mixture of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide.

[0045] The preparation method of the novel asymmetric wettable electrospinning double-layer membrane described in this example is as follows:

[0046] (1) Preparation...

Embodiment 2

[0049] An embodiment of the novel asymmetric wettable electrospinning double-layer membrane of the present invention, the novel asymmetric wettable electrostatic spinning double-layer membrane described in this embodiment includes a hydrophobic layer and a hydrophilic layer, so The hydrophobic layer and the hydrophilic layer are bonded and connected; the hydrophobic layer is made of hydrophobic materials, and the hydrophilic layer is made of hydrophilic materials. Described hydrophobic material is poly(lactic acid-glycolic acid) and polyacrylamide, and the mass ratio of described poly(lactic acid-glycolic acid) and polyacrylamide is: poly(lactic acid-glycolic acid):polyacrylamide=5: 1; the hydrophilic material comprises PEG-COOH, silk fibroin and a cross-linking agent; the mass ratio of the PEG-COOH to silk fibroin is: PEG-COOH: silk fibroin=10:3; the cross-linking agent The joint agent is a mixture of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysu...

Embodiment 3

[0054] An embodiment of the novel asymmetric wettable electrospun double-layer membrane of the present invention, the difference between the novel asymmetric wettable electrospun double-layer membrane described in this embodiment and Example 2 is only The difference lies in the hydrophilic material, the hydrophilic material comprises PEG-COOH, silk fibroin and cross-linking agent; the mass ratio of the PEG-COOH and silk fibroin is: PEG-COOH: silk fibroin=5: 1; The crosslinking agent is a mixture of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide.

[0055] The preparation method of the novel asymmetric wettable electrospinning double-layer membrane described in this example is as follows:

[0056] (1) Preparation of hydrophobic layer: with embodiment 2;

[0057] (2) Preparation of hydrophilic layer: Weigh 1.5g of carboxypolyethylene glycol (PEG-COOH) and 0.3g of silk fibroin dissolved in 10mL of hexafluoroisopropanol, stir for 12h with an e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com