Heat-insulating fluffy down quilt and preparation process thereof

A preparation process and technology for down quilts, applied in the field of down quilts, can solve problems such as poor bulkiness and poor antibacterial performance, and achieve the effects of good anti-felting performance, good antibacterial properties, and reduced damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A warm and fluffy duvet, comprising a duvet cover and an inner core, the inner core is wrapped with a duvet cover, and the inner core is filled with bamboo charcoal fiber and pretreated wool and down;

[0040] Wherein, the warm and fluffy duvet is prepared through the following steps:

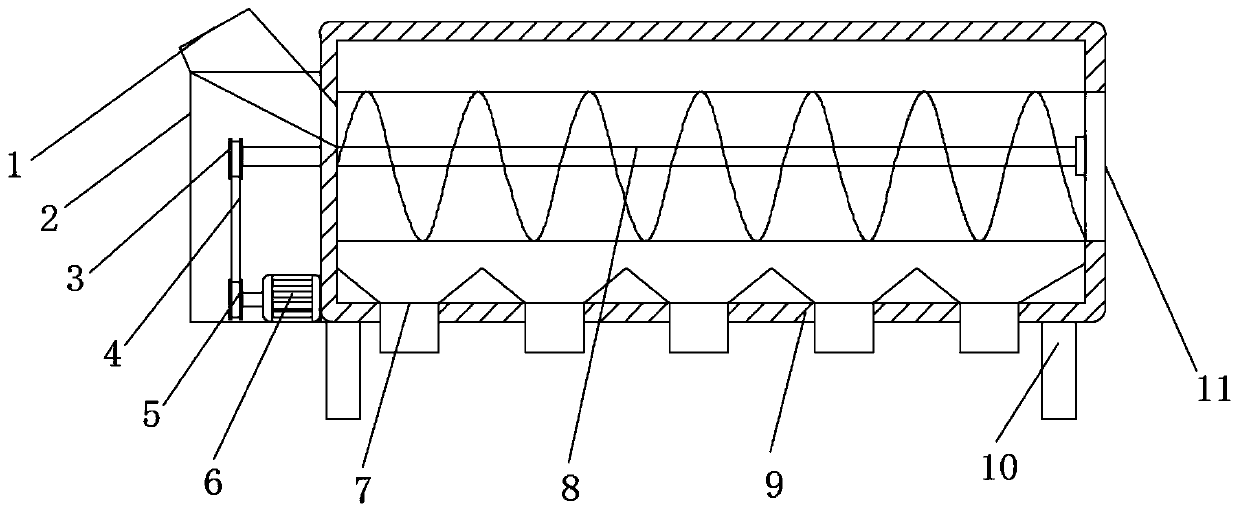

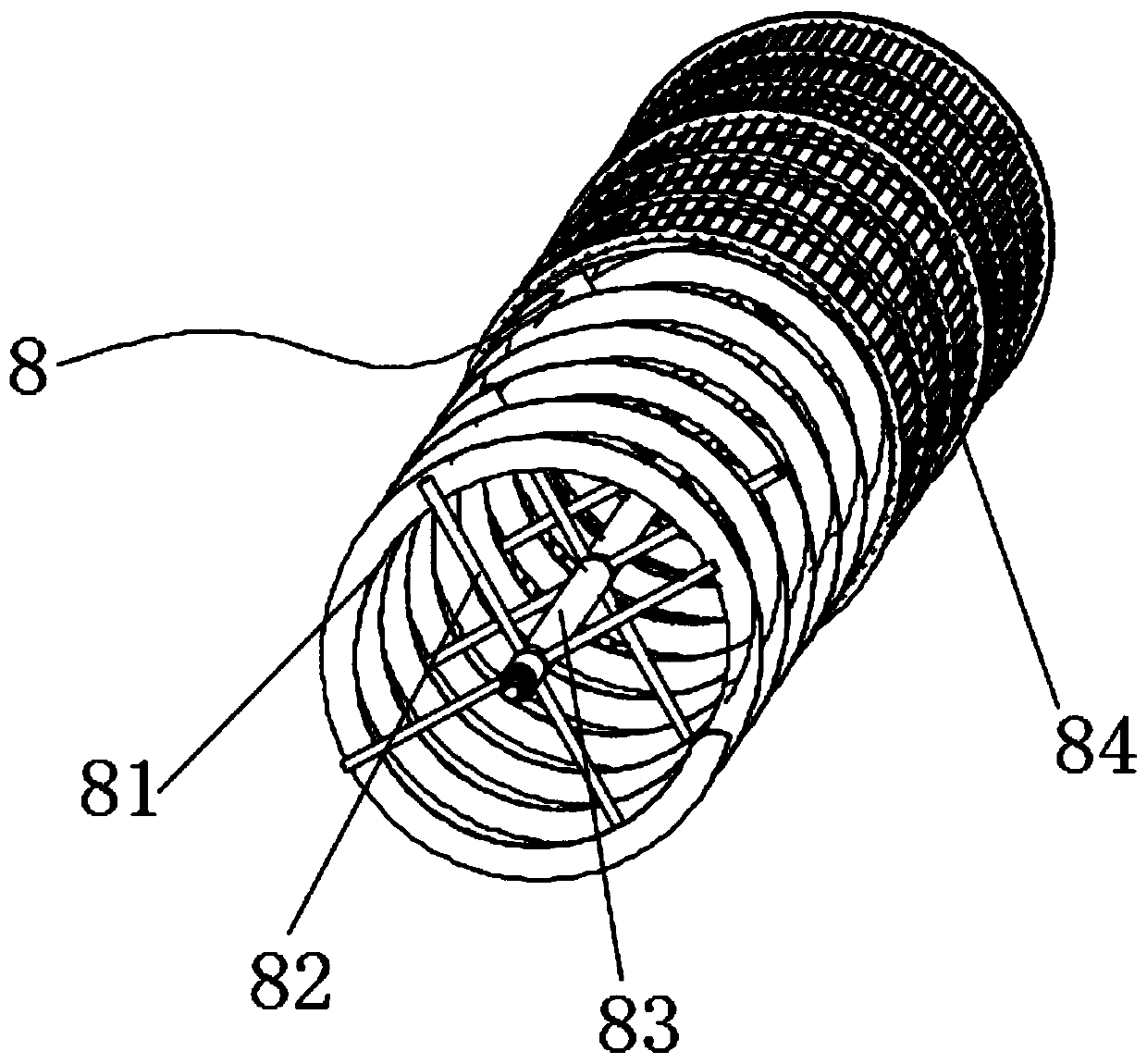

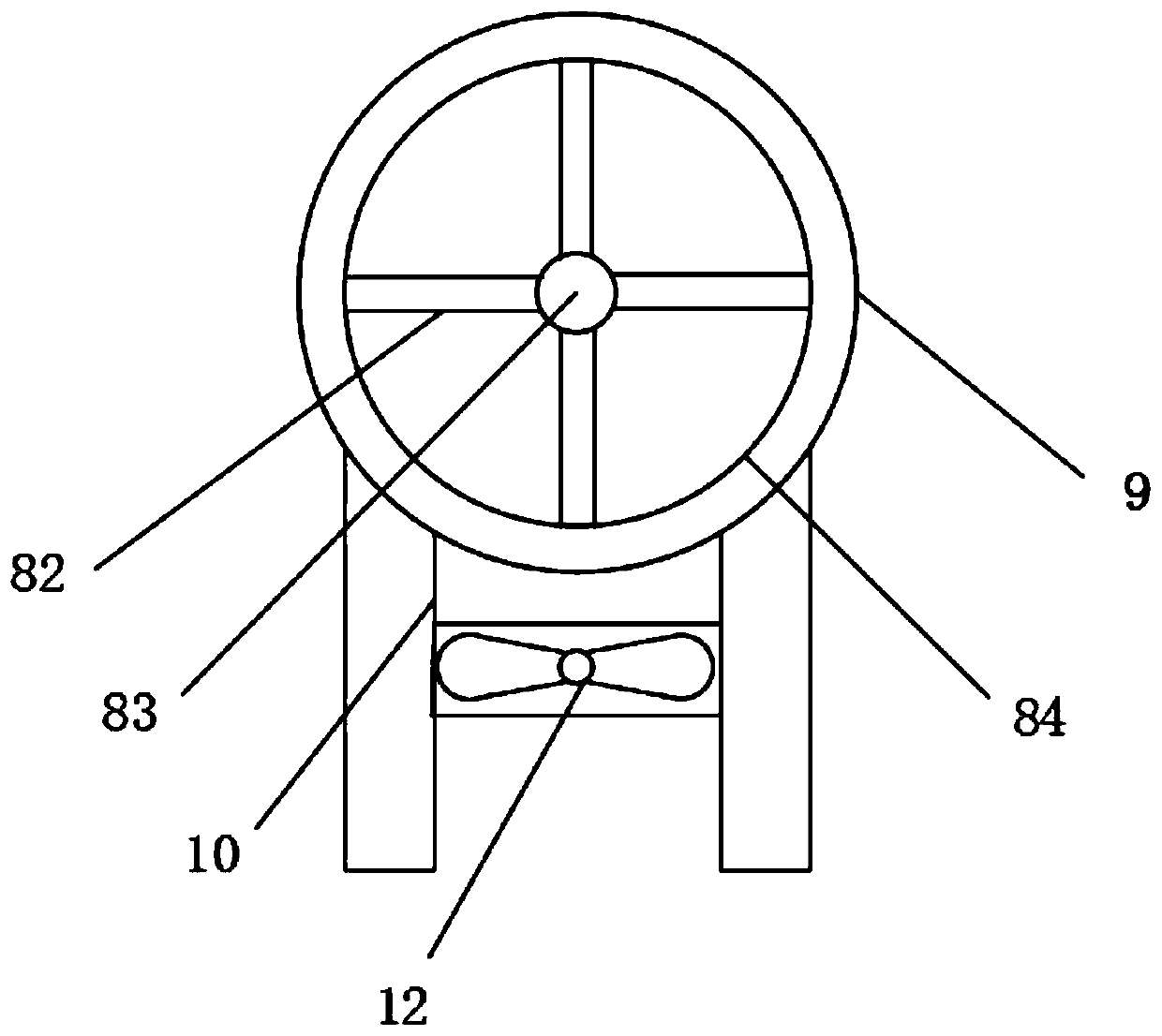

[0041]1) Down pretreatment: sterilization - destemming of raw materials - sand removal - fine separation - initial washing - washing - dehydration - drying; the method of fine separation is: pour the down through the feed funnel 1 of the down screening machine into the screening mechanism 8, the starter motor 6 rotates, drives the second pulley 5, drives the first pulley 3 to rotate through the belt 4, and then drives the screening mechanism 8 to rotate for the first screening. Carry out the second screening, and the small fluff is discharged from the discharge funnel 7;

[0042] 2) Wool pretreatment: add the wool fiber to the dichloroisocyanuric acid solution with a concentration of 1%...

Embodiment 2

[0050] A warm and fluffy duvet, comprising a duvet cover and an inner core, the inner core is wrapped with a duvet cover, and the inner core is filled with bamboo charcoal fiber and pretreated wool and down;

[0051] Wherein, the warm and fluffy duvet is prepared through the following steps:

[0052] 1) Down pretreatment: sterilization - destemming of raw materials - sand removal - fine separation - initial washing - washing - dehydration - drying; the method of fine separation is: pour the down through the feed funnel 1 of the down screening machine into the screening mechanism 8, the starter motor 6 rotates, drives the second pulley 5, drives the first pulley 3 to rotate through the belt 4, and then drives the screening mechanism 8 to rotate for the first screening. Carry out the second screening, and the small fluff is discharged from the discharge funnel 7;

[0053] 2) Wool pretreatment: add the wool fiber to the dichloroisocyanuric acid solution with a concentration of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com