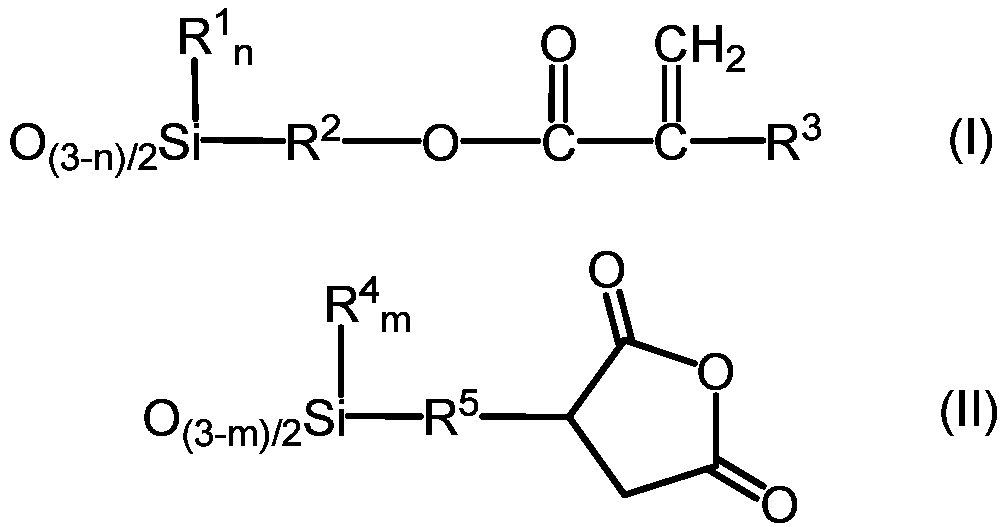

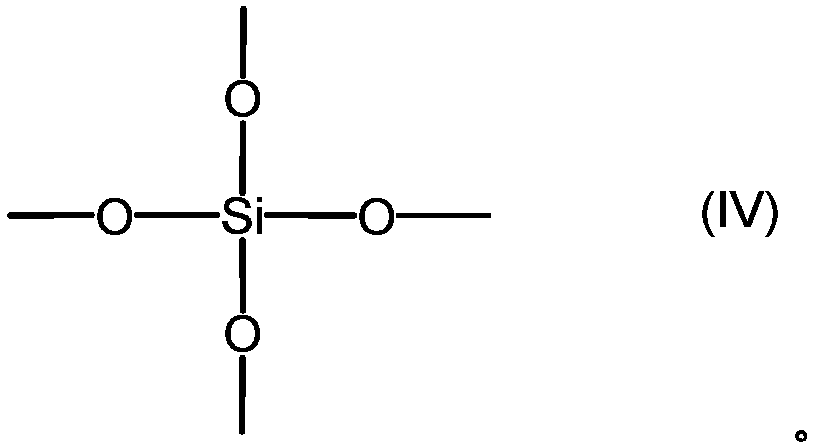

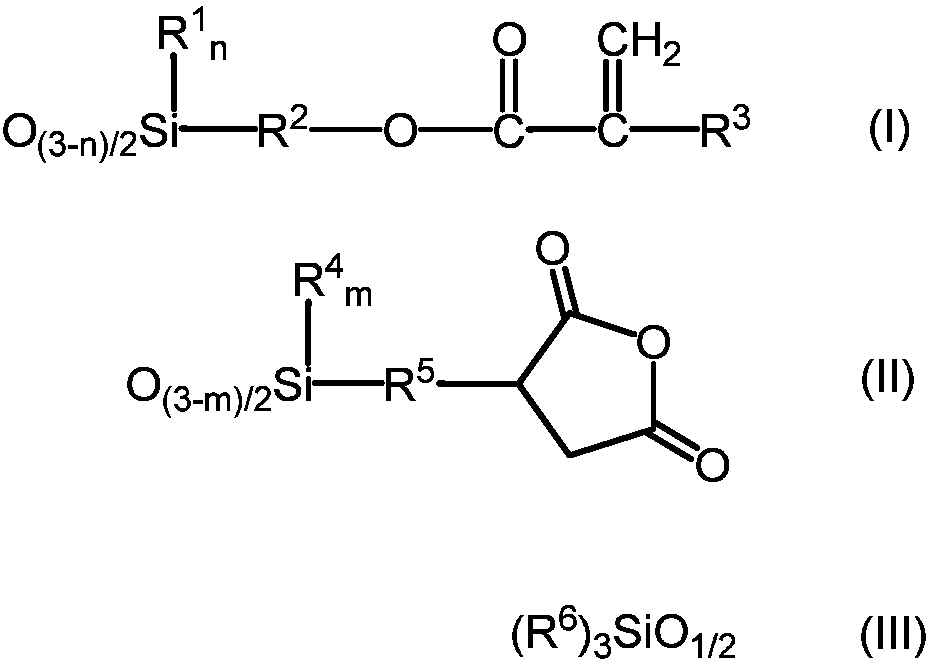

Organopolysiloxane compound and active energy ray curable composition containing the same

A curable composition and active energy ray technology, applied in organic chemistry, compounds of group 4/14 elements of the periodic table, chemical instruments and methods, etc., can solve problems such as corrosion of metal wiring parts and changes over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0112] 468.6g (2.0mol) of 3-acryloxypropyltrimethoxysilane, 262.3g (1.0mol) of 3-(trimethoxysilyl)propylsuccinic anhydride, 487.13g of hexamethyldisiloxane (3.0 mol) and 5.1 g of methanesulfonic acid were added to the reactor, and when it became uniform, 115.2 g of ion-exchanged water was added, and stirred at 25° C. for 4 hours. 25.3 g of Keyword 500SH (manufactured by Kyowa Chemical Industry Co., Ltd.) was charged, stirred for 2 hours, and neutralized. Volatile components such as methanol were distilled off under reduced pressure, and pressure filtration was performed.

[0113] The obtained reactant was a liquid having a viscosity of 890 mPa·s at 25° C., a volatile component of 6.4% by mass, and a weight average molecular weight of 1180. The values of a to g in the average formula (V) calculated from the results of NMR were a=0.29, b=0.13, c=0, d=0, e=0, f=0.58, and g=0.13, respectively.

Embodiment 1-2

[0115] 468.6g (2.0mol) of 3-acryloxypropyltrimethoxysilane, 524.7g (2.0mol) of 3-(trimethoxysilyl)propylsuccinic anhydride, 487.1g of hexamethyldisiloxane (3.0 mol) and 6.0 g of methanesulfonic acid were added to the reactor, and when it became uniform, 165.6 g of ion-exchanged water was added, and stirred at 25° C. for 2 hours. 30.1 g of Keyword 500SH (manufactured by Kyowa Chemical Industry Co., Ltd.) was added, stirred for 2 hours, and neutralized. Volatile components such as methanol were distilled off under reduced pressure, and pressure filtration was performed.

[0116] The obtained reactant was a liquid having a viscosity of 550 mPa·s at 25° C., a volatile content of 3.3% by mass, and a weight average molecular weight of 970. The values of a to g in the average formula (V) calculated from the results of NMR were a=0.26, b=0.26, c=0, d=0, e=0, f=0.48, g=0.11, respectively.

Embodiment 1-3

[0118] 702.9g (3.0mol) of 3-acryloxypropyltrimethoxysilane, 262.3g (1.0mol) of 3-(trimethoxysilyl)propylsuccinic anhydride, 487.1g of hexamethyldisiloxane (3.0 mol) and 5.1 g of methanesulfonic acid were charged into the reactor, and when it became uniform, 147.6 g of ion-exchanged water was added, and stirred at 25° C. for 4 hours. 25.3 g of Keyword 500SH (manufactured by Kyowa Chemical Industry Co., Ltd.) was charged, stirred for 2 hours, and neutralized. Volatile components such as methanol were distilled off under reduced pressure, and pressure filtration was performed.

[0119] The obtained reactant was a liquid having a viscosity of 190 mPa·s at 25° C., a volatile content of 4.1% by mass, and a weight average molecular weight of 1,210. The values of a to g in the average formula (V) calculated from the results of NMR were a=0.42, b=0.14, c=0, d=0, e=0, f=0.44, g=0.08, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com