Three-electrode system, electrochemical sensor and manufacturing method thereof, and electrochemical workstation and application thereof

A three-electrode system, electrochemical technology, applied in the field of detection, can solve the problems of quantitative detection of heavy metal ions, heavy metal ions, pollution, etc. The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

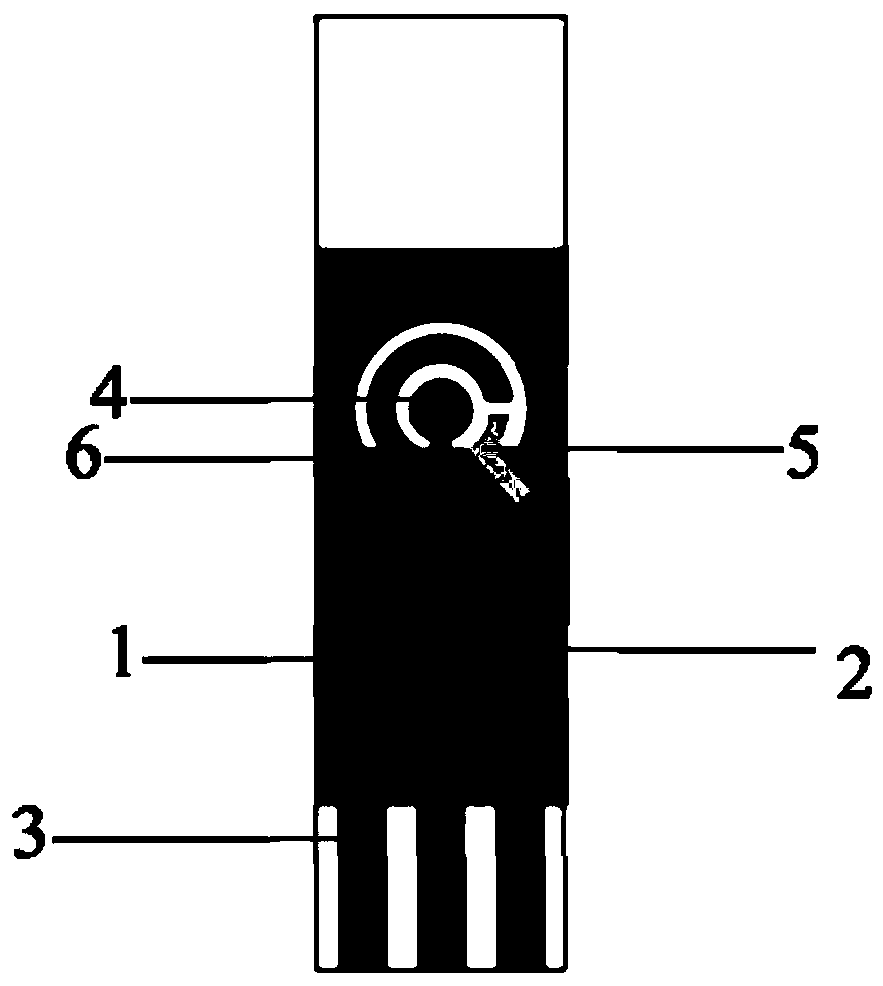

[0066] This embodiment provides a three-electrode system, such as figure 1 As shown, the three-electrode system includes a three-electrode system including a working electrode and a conductive layer on the surface of the working electrode conductive region 1, a reference electrode and a conductive layer on the surface 2 of the reference electrode conductive region, a counter electrode and a surface 3 of the counter electrode conductive region The conductive layer; the conductive layer is a mixture of carbon paste ink and silver paste ink; the conductive layer is a mixture of carbon paste ink and silver paste ink; wherein the molar ratio of carbon and silver in the conductive layer is 1:1; conduction The thickness of the layer is 10 μm; the surface of the working electrode working area 4 is printed with a carbon paste ink layer, and the thickness of the carbon paste ink layer is 15 μm; the surface of the reference electrode working area 5 is printed with a silver chloride layer,...

Embodiment 2

[0081] This embodiment provides a three-electrode system, which includes a working electrode and a conductive layer on the surface of the conductive region of the working electrode, a reference electrode and a conductive layer on the surface of the conductive region of the reference electrode, a counter electrode and a surface of the conductive region of the counter electrode The conductive layer; the conductive layer is a mixture of carbon paste ink and silver paste ink; wherein the molar ratio of carbon and silver in the conductive layer is 1:3; the thickness of the conductive layer is 15 μm; the surface of the working electrode area is printed with carbon The thickness of the carbon paste ink layer is 19 μm; the surface of the counter electrode working area is printed with a carbon paste ink layer, and the thickness of the carbon paste ink layer is 19 μm; the surface of the reference electrode working area is printed with a silver chloride layer, silver chloride The thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com