Low-temperature curing method for silver coated silica gel

A curing method, silver silica gel technology, applied in the direction of radioactive purification, nuclear engineering, etc., can solve the problems of unsatisfactory long-term disposal of radioactive iodine, the deformation of the solidified body affects the stability, etc., achieve good industrial application prospects, inhibit migration, and the process is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] In this example, the common iodine-127 is used to simulate the radionuclide iodine-129. A low-temperature curing method for silver-coated silica gel, comprising the following steps:

[0068] (1) mixing and grinding silica gel particles and AgI to obtain iodine-containing silver-coated silica gel particles, and filtering through a filter to obtain iodine-containing silver-coated silica gel particles with a maximum outer diameter less than or equal to 200 μm;

[0069] (2) Mix iodine-containing silver-coated silica gel particles with borate raw material powders (boron oxide, bismuth oxide and zinc oxide), grind after adding deionized water to obtain a wet mixture, and dry the wet mixture, A dry mixture is obtained; in the borate raw material powder, in terms of mass percentage, boron oxide is 60%, bismuth oxide is 28%, and zinc oxide is 12%. In actual use, boron oxide is 40% to 70%, bismuth oxide is 22% to 48%, and zinc oxide is 8% to 12%. In the dry mixture, silver-coate...

Embodiment 2

[0075] In this example, the common iodine-127 is used to simulate the radionuclide iodine-129. A low-temperature curing method for silver-coated silica gel, comprising the following steps:

[0076] (1) mixing and grinding silica gel particles and AgI to obtain iodine-containing silver-coated silica gel particles, and filtering through a filter to obtain iodine-containing silver-coated silica gel particles with a maximum outer diameter less than or equal to 200 μm;

[0077] (2) Mix iodine-containing silver-coated silica gel particles with borate raw material powders (boron oxide, bismuth oxide and zinc oxide), grind after adding deionized water to obtain a wet mixture, and dry the wet mixture, A dry mixture is obtained; in the borate raw material powder, according to mass percentage, boron oxide is 50%, bismuth oxide is 40%, and zinc oxide is 10%. In the dried mixture, by mass fraction, silver-coated silica gel is 65.65%, iodine element is 14.35%, and borate glass ceramic powd...

Embodiment 3

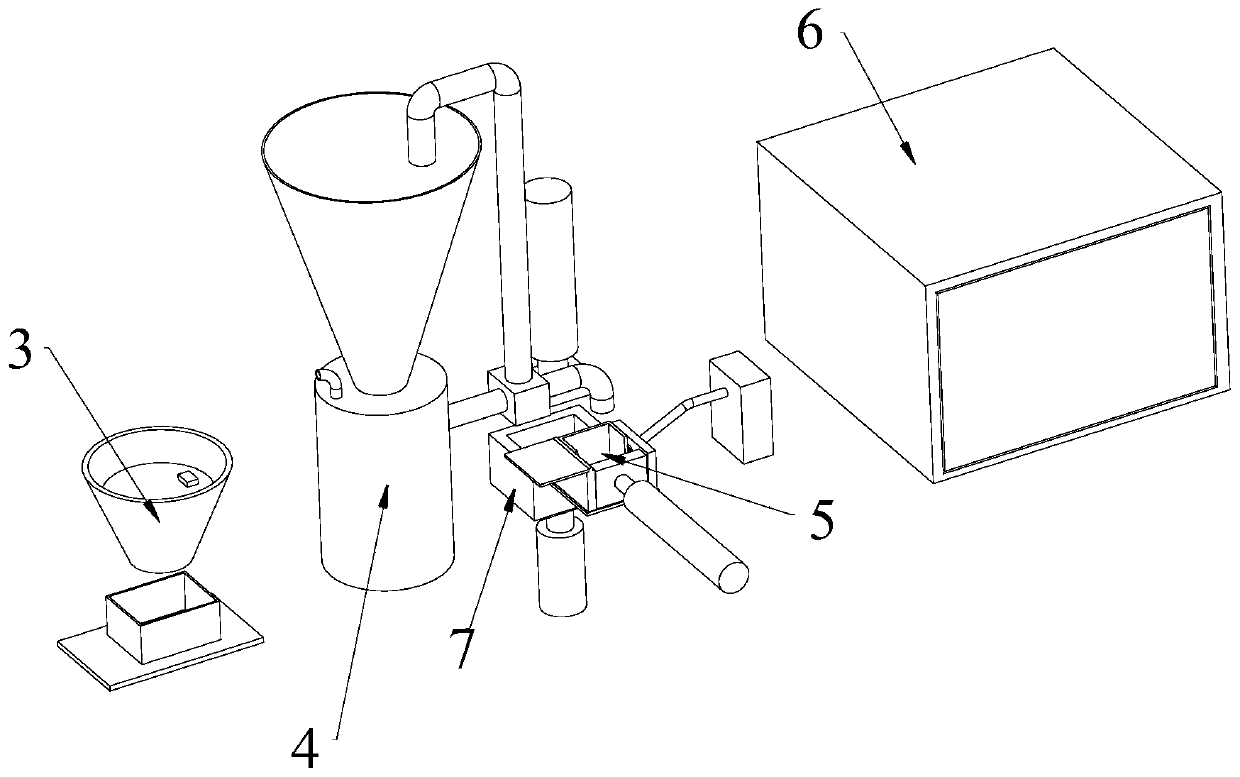

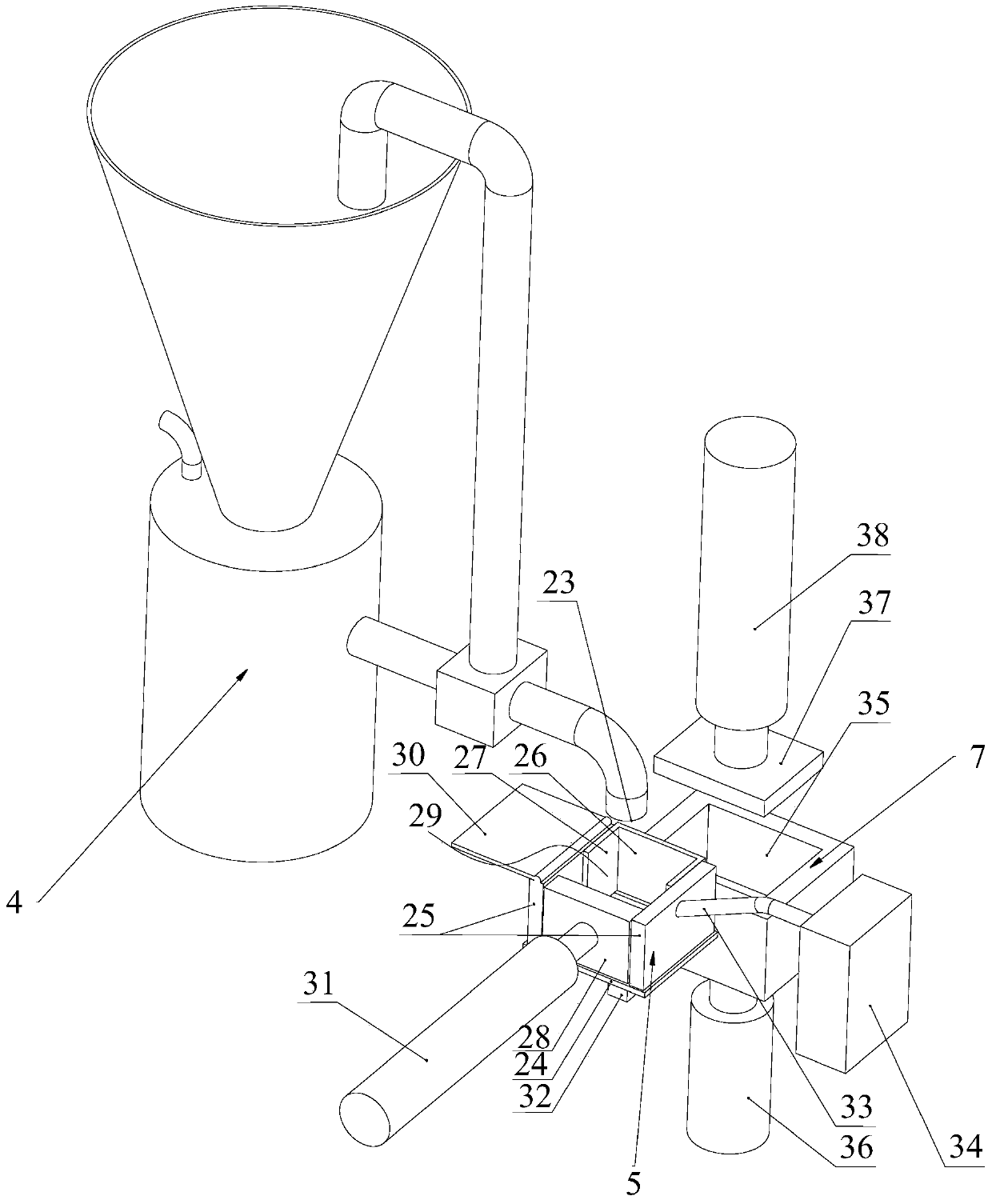

[0081] like figure 1 As shown, this embodiment discloses a curing device for implementing the method of the present application, and the curing device includes:

[0082] Silver-coated silica gel particle filter mechanism 3;

[0083] Colloid mill 4, for mixing and grinding silver-coated silica gel particles and borate raw material powder;

[0084] Drying device 5, is used for receiving the wet mixture from colloid mill 4, and to mixture drying, obtains dry mixture;

[0085] The second sintering device 6 is used for sintering the dried mixture.

[0086] The second sintering device 6 may be equipment such as a high-temperature muffle furnace or a microwave sintering furnace.

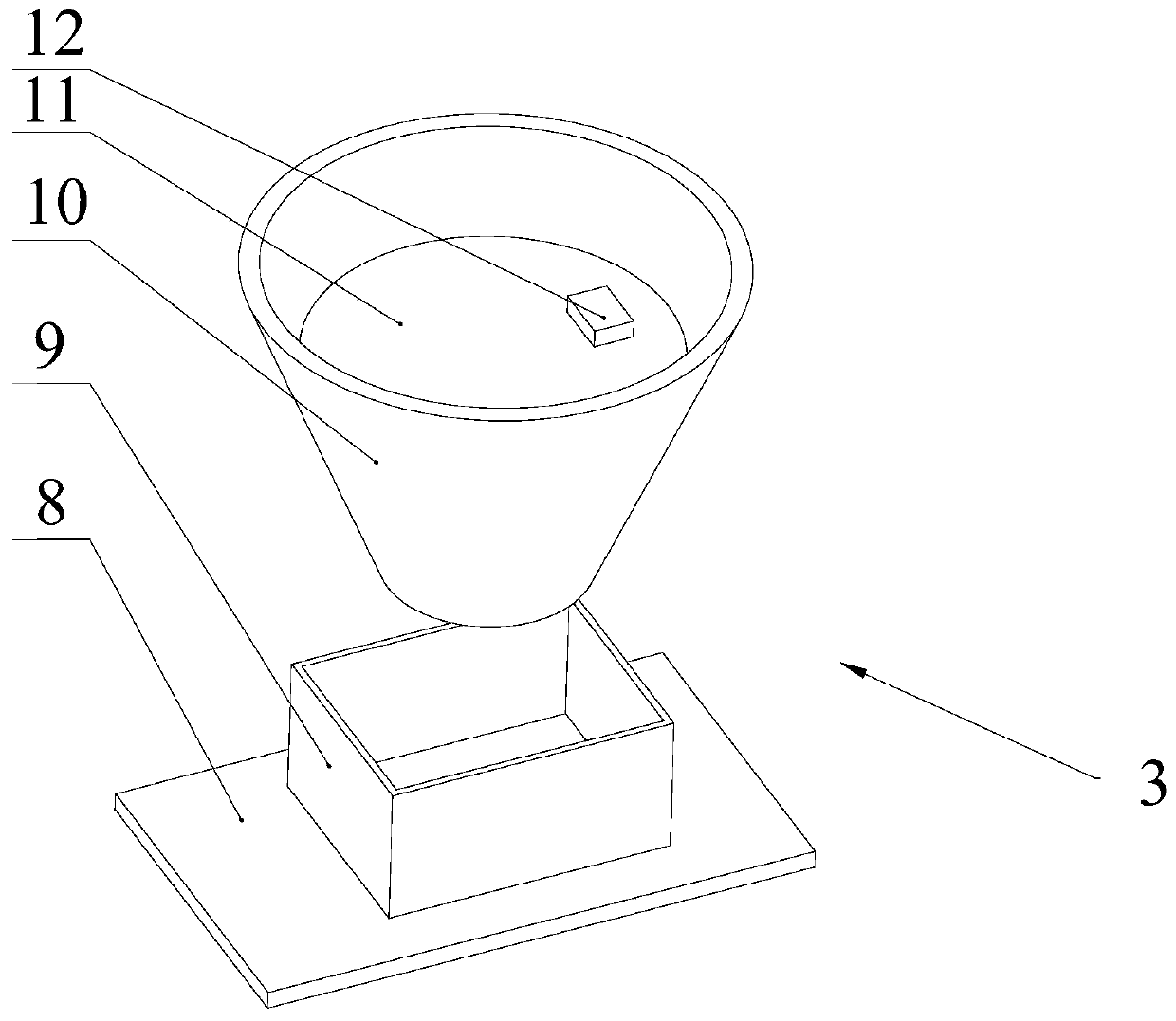

[0087] like figure 2 As shown, the silver-coated silica gel particle filter mechanism 3 includes:

[0088] weighing scale 8;

[0089] The first funnel 10 is arranged directly above the weighing scale 8;

[0090] Filter screen 11 is installed in the first funnel 10;

[0091] The first vibration moto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com