A kind of honeycomb type denitrification catalyst and preparation method thereof

A denitrification catalyst, honeycomb technology, applied in the field of selective catalytic reduction catalyst, to achieve the effect of low cost, excellent mechanical properties and anti-poisoning performance, and long operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

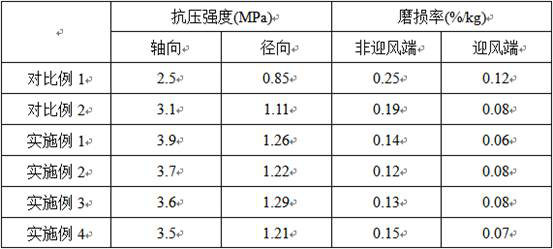

Examples

Embodiment 1

[0034] Weigh the sepiolite fiber, place it in 1mol / L HCl solution (solid-to-liquid ratio 1:80), and then add AEO-15 in an amount of 0.5% of the mass of the mineral fiber. Stir and reflux at 60°C for 5 hours, filter, dry, and roast at 500°C for 2 hours;

[0035] The roasted sepiolite fiber and TiO 2 Mix, add deionized water, attapulgite, ammonium metavanadate solution, ammonium metatungstate solution, polyvinyl alcohol, mix evenly to form a paste, extrude, dry, and calcined at 500°C for 2 hours to obtain Honeycomb denitrification catalyst.

[0036] The mass fraction ratio of paste ingredients is: 10% of calcined sepiolite fiber, TiO 2 70%, binder 5%, ammonium metavanadate 1%, ammonium metatungstate 4%, molding aid 5%, and the rest is water.

Embodiment 2

[0038] Weigh wollastonite fiber and place in 0.5mol / L HNO 3 In the solution (solid-to-liquid ratio 1:100), add AEO-10, the amount added is 2% of the mineral fiber mass. Stir and reflux at 90°C for 1 hour, filter, dry, and roast at 400°C for 5 hours;

[0039] The fired wollastonite fiber and TiO 2 Mix, add deionized water, Al 2 o 3 , ammonium metavanadate solution, ammonium metatungstate solution, and carboxymethyl cellulose, mixed evenly to form a paste, extruded, dried, and calcined at 400°C for 6 hours to obtain a honeycomb denitration catalyst.

[0040] The mass fraction ratio of the paste components is: 5% wollastonite fiber after roasting, TiO 2 65%, binder 1%, ammonium metavanadate 0.5%, ammonium metatungstate 2.5%, molding aid 2.5%, and the rest is water.

Embodiment 3

[0042] Weigh wollastonite fiber and place in 5mol / L H 2 SO 4 Solution (solid-to-liquid ratio 1:20), then add OP-10, the amount added is 5% of the mineral fiber mass. Stir and reflux at 50°C for 8 hours, filter, dry, and roast at 600°C for 1 hour;

[0043] The fired wollastonite fiber and TiO 2 Mix, add deionized water, clay, ammonium metavanadate solution, ammonium metatungstate solution, hydroxypropyl cellulose, mix evenly to form a paste, extrude, dry, and calcined at 600°C for 1 hour to obtain Honeycomb denitrification catalyst.

[0044] The mass fraction ratio of paste ingredients is: 1% wollastonite fiber after roasting, TiO 2 50%, binder 2%, ammonium metavanadate 1.5%, ammonium metatungstate 3%, molding aid 1%, and the rest is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com