Modified baijiu distiller grain-based activated carbon and preparation method thereof

A technology of distiller's grains and activated carbon, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as lack, and achieve the effects of easy operation, suitable for industrial production, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

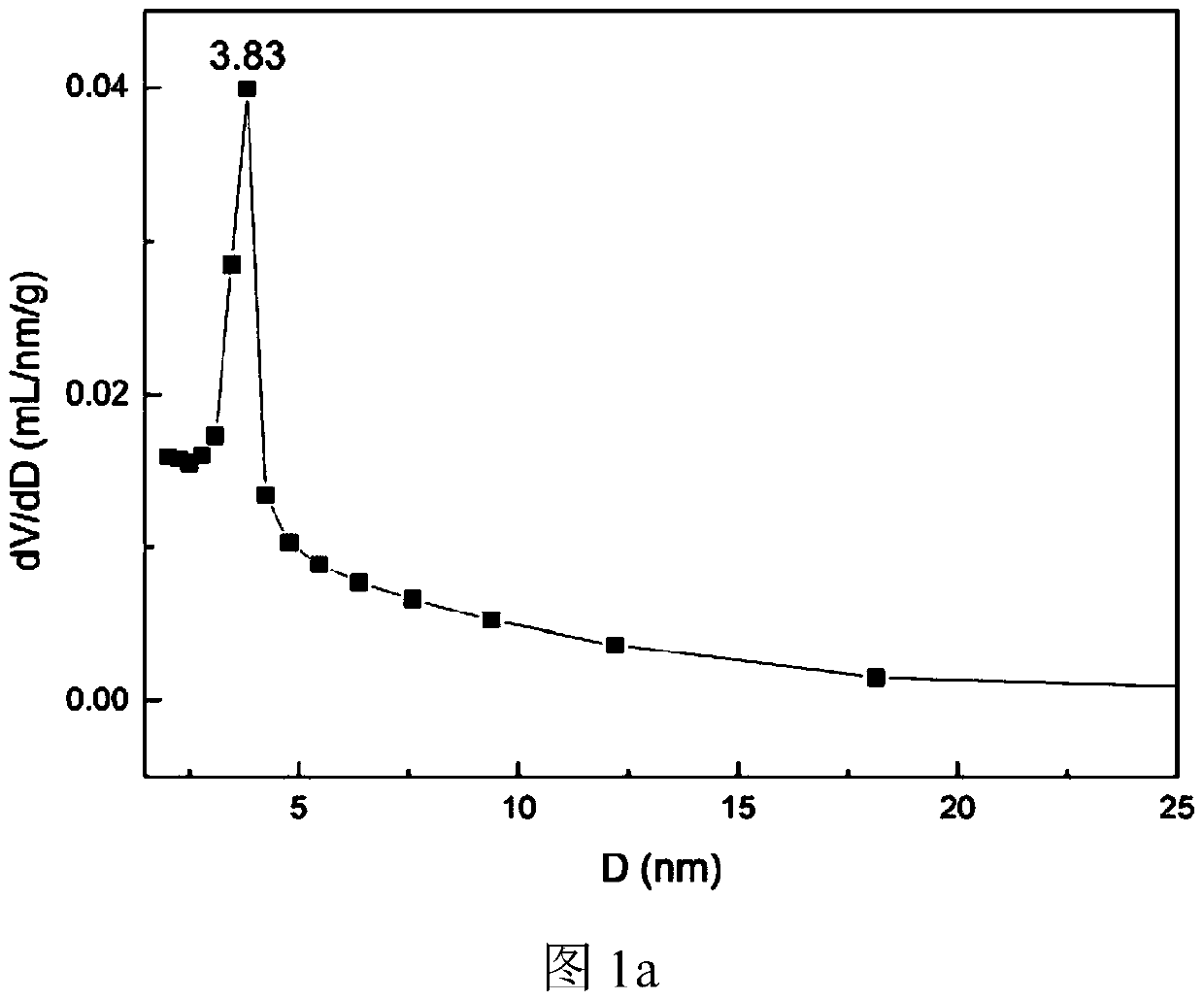

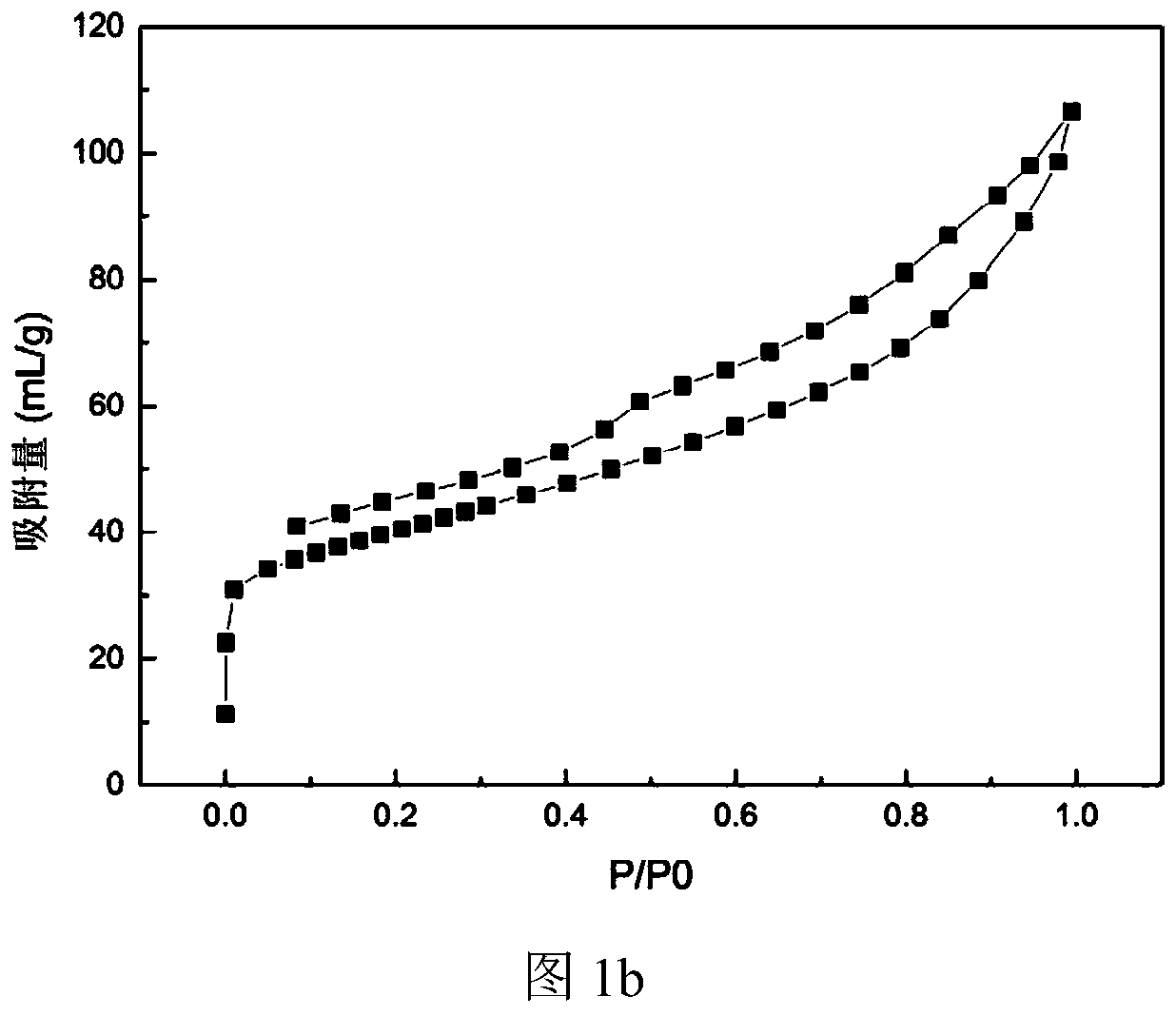

Embodiment 1

[0029] A preparation method of modified distiller's grains-based activated carbon, comprising the following steps:

[0030] (1) Pulverize the dried distiller's grains to 80 mesh with a pulverizer, then weigh 10g of distiller's grains powder in N 2 High temperature carbonization at 800℃ for 1h under atmosphere;

[0031] (2) Add 2g of potassium hydroxide to the hydrothermal reaction kettle, then add 15mL of deionized water, ultrasonically dissolve to form a homogeneous solution, then add 2g of carbonized distiller's grains powder, mix well, and heat at 180°C Undertake hydrothermal reaction for 20 hours; after the hydrothermal reaction kettle is cooled to room temperature, filter it with suction and wash it with deionized water, and then dry it in an oven at 100°C to prepare activated carbon;

[0032] (3) immerse 1 g of activated carbon in a melamine solution with a mass fraction of 0.1% at a temperature of 70° C. for 3 h;

[0033] (4) Suction filtration and drying at 100°C aft...

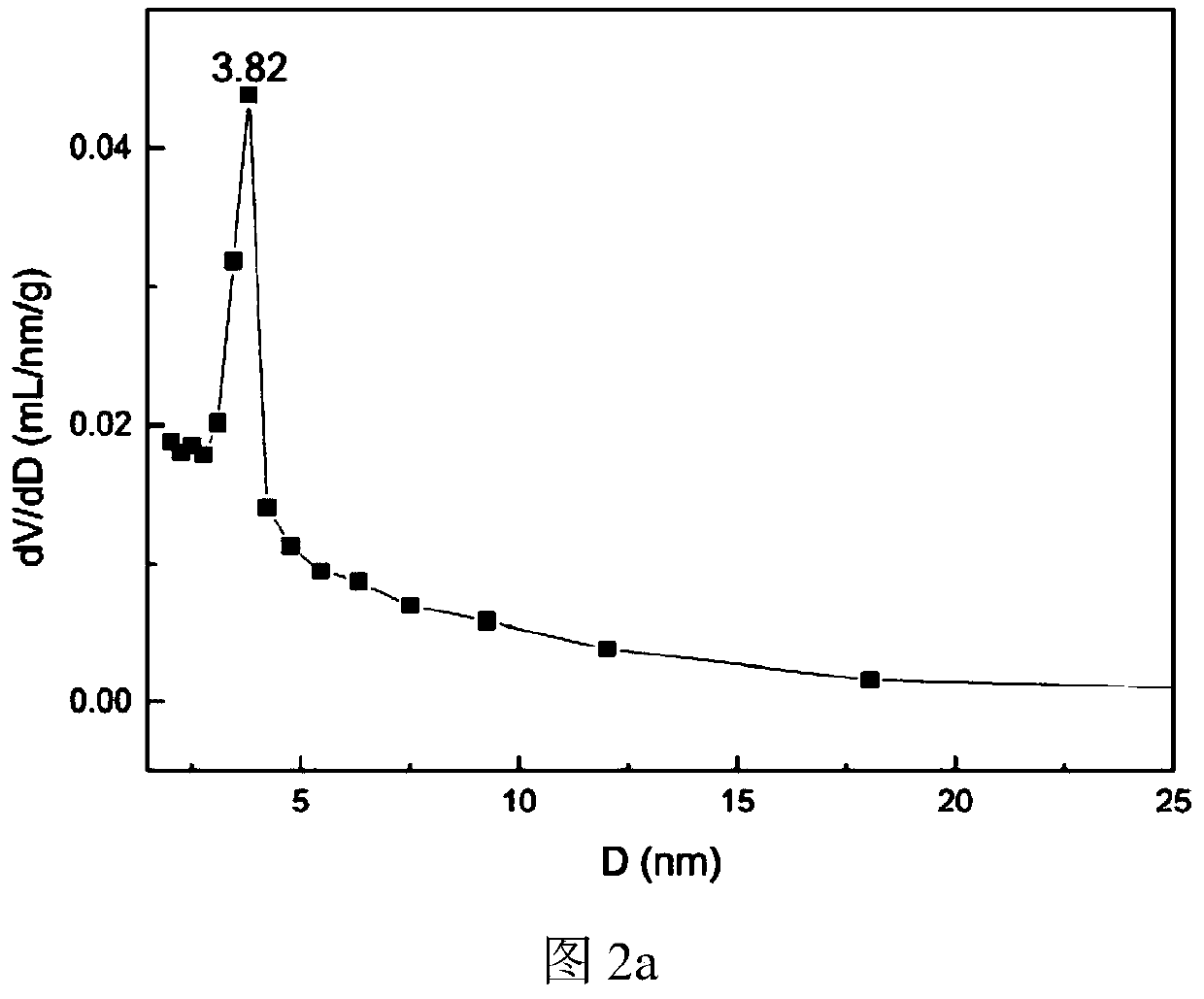

Embodiment 2

[0036] A preparation method of modified distiller's grains-based activated carbon, comprising the following steps:

[0037] (1) Pulverize the dried distiller's grains to 100 mesh with a pulverizer, then weigh 10g of distiller's grains powder in N 2 High temperature carbonization at 700℃ for 1h under atmosphere;

[0038] (2) Add 2g of potassium hydroxide to the hydrothermal reaction kettle, then add 15mL of deionized water, ultrasonically dissolve to form a homogeneous solution, then add 2g of carbonized distiller's grains powder, mix well, and heat at 180°C Undertake hydrothermal reaction for 16 hours; after the hydrothermal reaction kettle is cooled to room temperature, filter it with suction and wash it with deionized water, and then dry it in an oven at 100°C to prepare activated carbon;

[0039] (3) immerse 1 g of activated carbon in a melamine solution with a mass fraction of 0.3% at a temperature of 80° C. for 3 h;

[0040] (4) Suction filtration and drying at 100°C af...

Embodiment 3

[0043] A preparation method of modified distiller's grains-based activated carbon, comprising the following steps:

[0044] (1) Grind the dried distiller's grains to 100-150 mesh with a pulverizer, then weigh 10 g of distiller's grains powder in N 2 High temperature carbonization at 800°C for 2 hours under atmosphere;

[0045](2) Add 2g of potassium carbonate to the hydrothermal reaction kettle, then add 15mL of deionized water, ultrasonically dissolve to form a homogeneous solution, then add 2g of carbonized distiller’s grains powder, mix well, and water under the condition of 180°C Thermal reaction for 16 hours; after the hydrothermal reaction kettle was cooled to room temperature, suction filtered and washed with deionized water, and then dried in an oven at 100°C to prepare activated carbon;

[0046] (3) immerse 1 g of activated carbon in a melamine solution with a mass fraction of 0.4% at a temperature of 80° C. for 3 h;

[0047] (4) Suction filtration and drying at 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com